Are you gearing up for an interview for a Tuber Machine Operator Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tuber Machine Operator Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

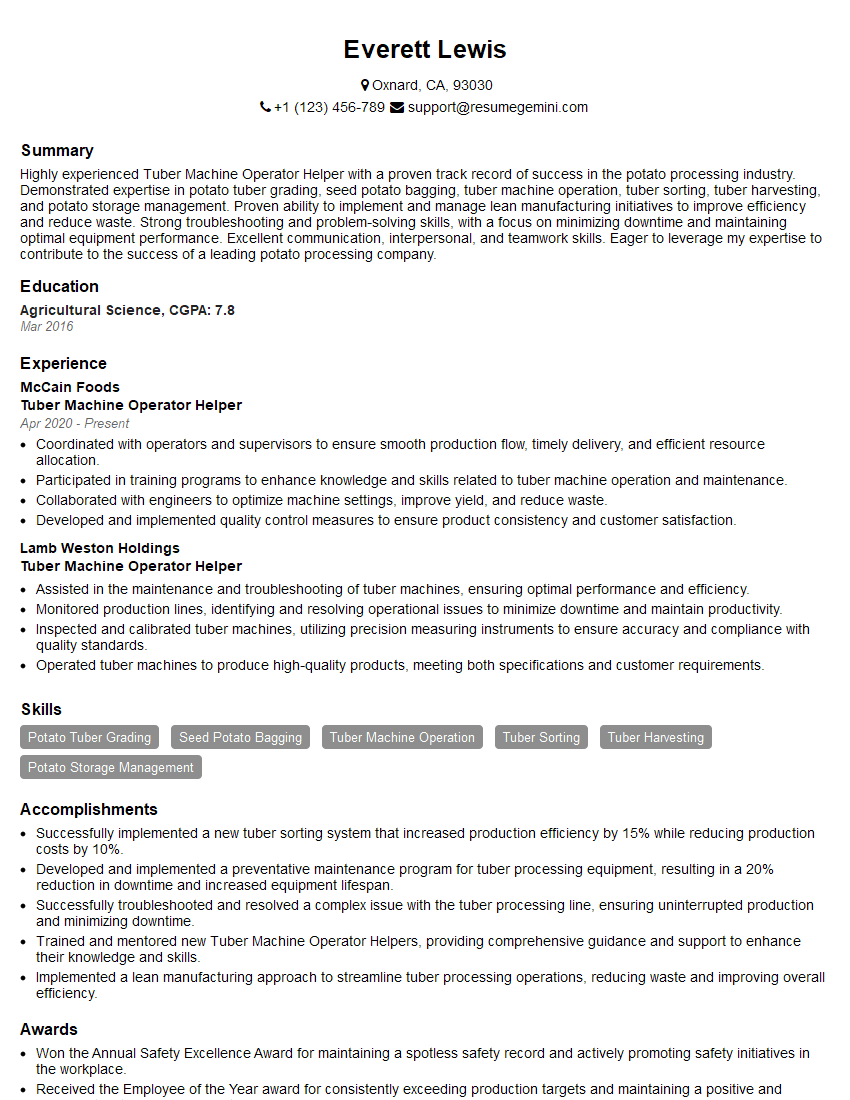

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tuber Machine Operator Helper

1. Describe the core responsibilities of a Tuber Machine Operator Helper?

- Assist the operator in setting up, operating, and maintaining tuber machines.

- Load and unload tubers into and out of the machines.

- Monitor the machines for proper operation and make adjustments as needed.

- Clean and maintain the machines and work area.

- Follow all safety procedures and regulations.

2. Explain the different types of tuber machines and their functions?

Potato tuber grading machine:

- Grading potatoes based on size, shape, and quality.

- Separating potatoes into different categories for packaging and sale.

Potato tuber planting machine:

- Planting potato tubers in rows at a specific depth and spacing.

- Ensuring proper tuber placement for optimal growth and yield.

3. What are the safety precautions that must be taken when operating tuber machines?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Keep hands and loose clothing away from moving parts.

- Never reach into the machine while it is running.

- Follow all lockout/tagout procedures before performing maintenance or repairs.

- Be aware of potential hazards, such as electrical shock, cuts, and bruises.

4. How do you troubleshoot common problems with tuber machines?

- Check for any loose or damaged parts.

- Inspect electrical connections and wiring.

- Clean any debris or obstructions from the machine.

- Check the settings and make sure they are correct.

- Refer to the manufacturer’s manual for specific troubleshooting steps.

5. What is the importance of proper maintenance for tuber machines?

- Ensures the machines are operating efficiently and effectively.

- Minimizes downtime and lost productivity.

- Extends the lifespan of the machines.

- Reduces the risk of accidents and injuries.

- Helps maintain the quality of the tubers being processed.

6. How do you ensure the accuracy and efficiency of the tuber grading process?

- Calibrate the grading machine regularly.

- Inspect tubers for defects before grading.

- Monitor the grading process closely and make adjustments as needed.

- Use a variety of grading methods to ensure accuracy, such as weight, size, and shape.

- Train operators on proper grading techniques.

7. What are the different types of tubers that can be processed using tuber machines?

- Potatoes

- Sweet potatoes

- Yams

- Carrots

- Beets

8. What is the role of automation in modern tuber processing plants?

- Increases efficiency and productivity.

- Reduces labor costs.

- Improves accuracy and consistency.

- Minimizes waste and spoilage.

- Enhances traceability and quality control.

9. What are the environmental considerations for tuber processing plants?

- Managing water usage and wastewater treatment.

- Reducing energy consumption and emissions.

- Minimizing waste and promoting recycling.

- Protecting the surrounding environment from noise and pollution.

- Complying with environmental regulations and standards.

10. How do you stay updated on the latest advancements in tuber processing technology?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Visit industry websites and online forums.

- Network with other professionals in the field.

- Take continuing education courses or certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tuber Machine Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tuber Machine Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tuber Machine Operator Helpers work under the supervision of experienced Tuber Machine Operators to perform various tasks related to the operation of tuber machines in the agricultural industry. Their primary responsibilities include the following:

1. Machine Operation

Assist in the loading, unloading, and operation of tuber machines used for planting, harvesting, and processing various tuber crops.

- Ensure proper setup and calibration of machines according to specifications.

- Monitor machine performance and make necessary adjustments to maintain optimal efficiency.

2. Crop Management

Inspect and assess crop conditions before and during machine operation to ensure proper planting and harvesting.

- Identify and remove any obstacles or debris from the field that could damage machines or hinder crop growth.

- Adjust machine settings to accommodate varying field conditions and crop characteristics.

3. Maintenance and Cleaning

Perform routine maintenance and cleaning tasks on tuber machines to ensure proper functioning and extend their lifespan.

- Clean and lubricate machine components to prevent wear and tear.

- Inspect and replace worn or damaged parts as needed.

4. Safety and Compliance

Follow established safety protocols and regulations related to the operation of tuber machines.

- Wear appropriate personal protective equipment (PPE) at all times.

- Operate machines in accordance with manufacturer’s guidelines and industry best practices.

Interview Tips

Preparing thoroughly for your interview is crucial to showcasing your skills and making a positive impression on potential employers:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific responsibilities of the Tuber Machine Operator Helper role.

- Visit the company website and social media pages.

- Review the job description thoroughly to understand the key requirements and expectations.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to emphasize the skills and experience that are most relevant to the position.

- Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Prepare specific examples of times when you successfully operated tuber machines or performed related tasks.

3. Practice Common Interview Questions

Research common interview questions and prepare thoughtful answers that highlight your strengths and qualifications.

- Review general interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Prepare answers to technical questions related to tuber machine operation and maintenance.

4. Demonstrate Enthusiasm and a Strong Work Ethic

Convey your passion for working with tuber machines and your commitment to performing at a high level.

- Share examples of your previous work experiences where you demonstrated strong attention to detail and a willingness to go the extra mile.

- Express your interest in learning and growing within the role and the company.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows your interest in the position and the company.

- Questions about the company’s future plans or the specific challenges faced by the team demonstrate your engagement.

- Inquire about opportunities for professional development or training within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tuber Machine Operator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tuber Machine Operator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.