Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tubing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tubing Machine Operator so you can tailor your answers to impress potential employers.

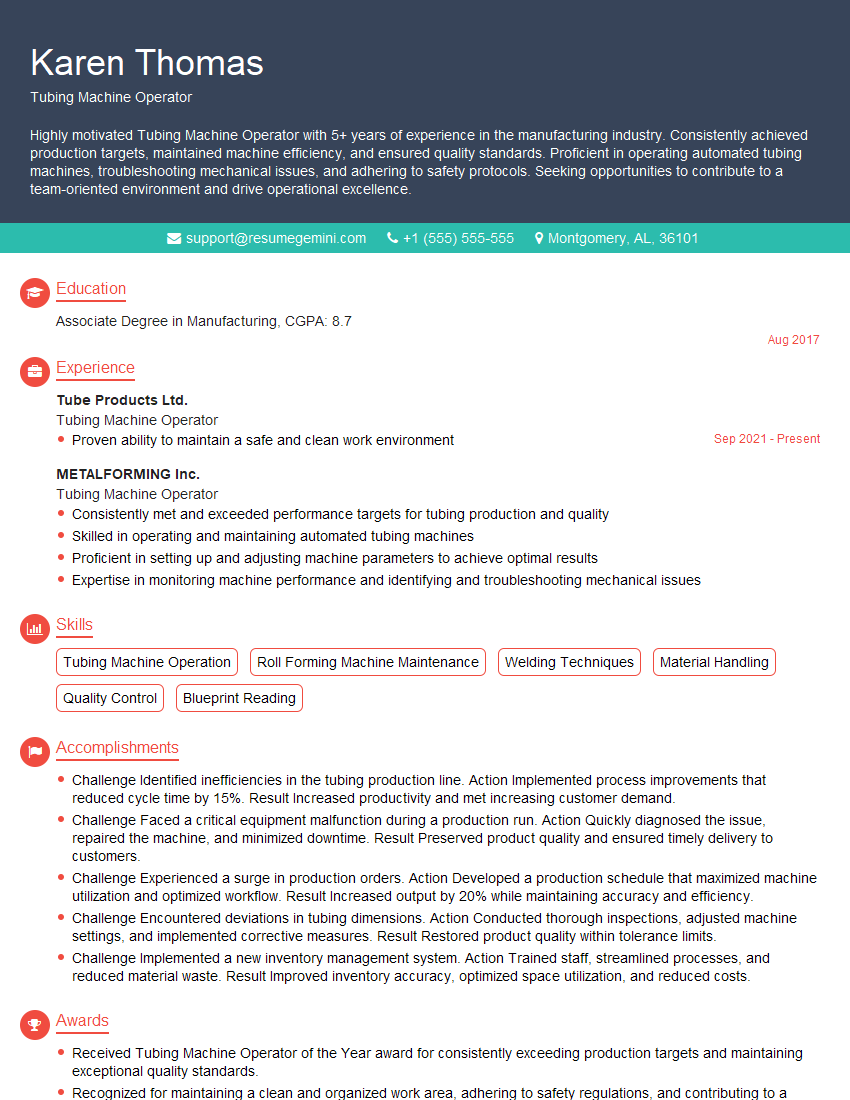

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tubing Machine Operator

1. What are the different types of tubing machines and their applications?

- Rotary Tube Machines: Used for high-volume production of precise, thin-walled tubes from ferrous and non-ferrous materials.

- Extrusion Tube Machines: Employed for creating seamless tubes with thicker walls from various metals.

- Cold Pilger Tube Machines: Specialized in producing high-strength, precision tubes with smooth inner and outer surfaces.

- Hydroforming Tube Machines: Utilizes pressurized fluid to shape tubes into complex geometries.

- Welding Tube Machines: Join tube sections together using welding techniques.

2. Explain the process of setting up and operating a tubing machine.

Pre-Setup

- Select and prepare the correct tooling for the desired tube size and material.

- Calibrate the machine according to manufacturer specifications.

Operation

- Feed the raw material into the machine.

- Monitor and adjust machine parameters (e.g., speed, temperature) as needed.

- Inspect finished tubes for quality and repeatability.

3. How do you ensure the quality of tubes produced on the tubing machine?

- Dimensional Inspection: Use precision measuring tools to verify tube dimensions meet specifications.

- Surface Inspection: Check for any defects, scratches, or imperfections on the tube surface.

- Material Testing: Conduct tensile or hardness tests to ensure material properties meet requirements.

- Calibration and Maintenance: Regularly calibrate and maintain the machine to prevent deviations in performance.

4. What are the common maintenance procedures for tubing machines?

- Regular Cleaning: Remove debris and contaminants from the machine to prevent damage.

- Lubrication: Apply lubricants to moving parts to reduce friction and extend component life.

- Tooling Inspection: Inspect tooling for wear or damage and replace as necessary.

- Calibration Verification: Periodically verify machine calibration to ensure ongoing accuracy.

5. Describe the different types of materials used in tubing production and their properties.

- Steel: Strong, durable, and versatile; suitable for various applications.

- Stainless Steel: Corrosion-resistant, ideal for food or chemical processing industries.

- Aluminum: Lightweight, corrosion-resistant, and good electrical conductivity.

- Copper: Excellent electrical and thermal conductivity, used in electrical wiring and plumbing.

- Plastics: Non-metallic materials with varying properties (e.g., flexibility, resistance to chemicals).

6. Explain the safety precautions that must be followed when operating a tubing machine.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Never operate the machine without proper training and supervision.

- Keep the work area clean and free of tripping hazards.

- Follow all lockout/tagout procedures before performing maintenance or adjustments.

- Report any accidents or near-misses immediately to the supervisor.

7. How do you troubleshoot common problems that may arise during tubing production?

Describe specific examples of troubleshooting and how you resolve them:

- Tube deformation: Adjust machine settings, check tooling alignment, or replace worn tooling.

- Surface defects: Clean the machine and tooling, adjust operating parameters, or use higher-quality material.

- Dimensional deviations: Recalibrate the machine, check tooling accuracy, or adjust process variables.

8. Explain the different types of cutting tools used in tubing production and their applications.

- Circular Saws: General-purpose cutting for straight cuts or miters.

- Band Saws: Used for curved or contoured cuts.

- Water Jet Cutters: Precision cutting using a high-pressure water jet.

- Plasma Cutters: High-heat cutting for thick metal tubes.

- Laser Cutters: Precise cutting of complex shapes with minimal heat distortion.

9. How do you optimize the production efficiency of a tubing machine?

- Equipment Calibration: Ensure accurate and consistent machine performance.

- Tooling Selection: Use the appropriate tools for the material and required precision.

- Process Optimization: Adjust machine parameters (e.g., speed, temperature) for maximum efficiency.

- Minimizing Waste: Implement strategies to reduce scrap and material loss.

10. Describe your experience in working with different types of tubing machines.

Provide specific examples of the machines you have operated and the tasks you performed:

- Rotary Tube Machine: Produced thin-walled steel tubes for automotive applications.

- Extrusion Tube Machine: Manufactured seamless copper tubes for plumbing and electrical systems.

- Hydroforming Tube Machine: Shaped complex geometry tubes for aircraft components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tubing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tubing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tubing Machine Operators are responsible for operating and monitoring tubing machines that produce tubes and pipes for various industries.

1. Machine Operation

intro paragraph

- Operate and monitor tubing machines to produce tubes and pipes of specified dimensions and tolerances.

- Set up, calibrate, and adjust machines to ensure optimal performance and product quality.

2. Production Monitoring

intro paragraph

- Monitor production processes to ensure smooth operation and identify any potential issues.

- Inspect tubes and pipes for defects and quality conformance.

3. Maintenance

intro paragraph

- Perform routine maintenance and cleaning of tubing machines to maintain optimal performance.

- Identify and troubleshoot machine malfunctions and take corrective actions.

4. Quality Control

intro paragraph

- Conduct quality control checks on finished tubes and pipes to ensure they meet specifications.

- Document production parameters, quality control data, and any deviations from specifications.

Interview Tips

Preparing for an interview for the position of Tubing Machine Operator requires careful planning and research. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s values, products, and industry standing. This will allow you to demonstrate your alignment with the company’s goals and values during the interview.

- Visit the company’s website to learn about its history, mission, and recent news.

- Read industry publications and articles to stay updated on the latest trends and technologies.

- Practice your answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining tubing machines. Quantify your achievements by providing specific examples of how you have contributed to production efficiency and quality.

- Describe your experience in setting up and calibrating tubing machines to meet production specifications.

- Explain how you have identified and resolved machine malfunctions, minimizing downtime and maximizing productivity.

3. Showcase Your Quality Control Expertise

Demonstrate your understanding of quality control procedures and your commitment to delivering high-quality products. Explain how you have implemented quality checks and ensured product compliance with industry standards.

- Discuss your experience in conducting visual inspections, dimensional measurements, and other quality control tests.

- Provide examples of how you have identified and addressed quality deviations, maintaining product integrity and customer satisfaction.

4. Emphasize Teamwork and Communication

Tubing Machine Operators often work in a team environment and must communicate effectively with colleagues and supervisors. Highlight your interpersonal skills and ability to collaborate with others.

- Explain how you have effectively communicated production updates, troubleshooting results, and quality control findings to relevant parties.

- Describe your experience in working as part of a team to resolve production issues and achieve operational goals.

Next Step:

Now that you’re armed with the knowledge of Tubing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tubing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini