Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tubing Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

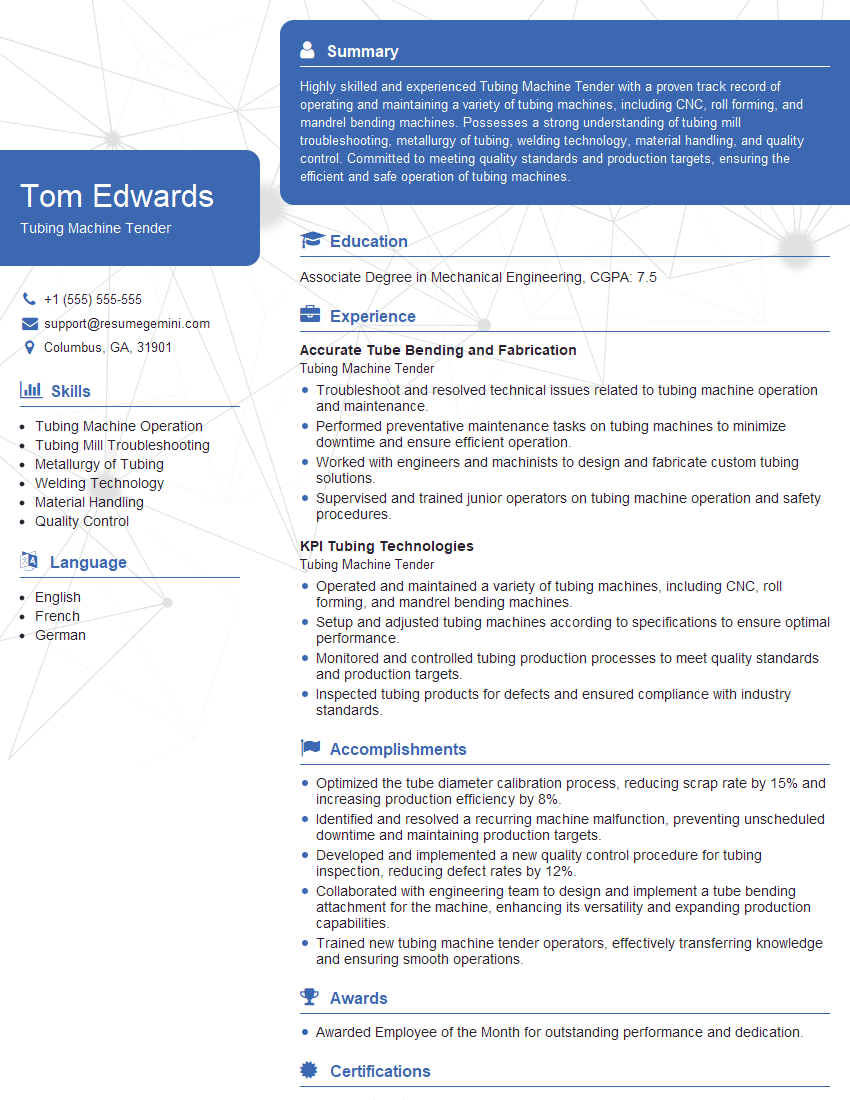

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tubing Machine Tender

1. Describe the key steps involved in tubing machine operation?

- Set up the machine according to specifications, including loading and aligning the tubing.

- Control the machine’s operation, ensuring smooth production and quality.

- Monitor the tubing’s dimensions, pressure, and temperature to maintain optimal conditions.

- Make adjustments to the machine’s settings to address any deviations or defects.

- Unloading and preparing the finished tubing for further processing or packaging.

2. How do you ensure the quality of the tubing produced by the machine?

In-Process Checks:

- Regularly inspect the tubing during production for any defects or imperfections.

- Continuously monitor the machine’s performance and adjust settings as needed.

- Take measurements of the tubing’s dimensions and compare them to specifications.

Post-Production Checks:

- Conduct final inspections of the finished tubing to ensure adherence to quality standards.

- Use precision measuring tools to verify dimensions and tolerances.

- Check for defects, such as leaks, cracks, or surface imperfections.

3. What maintenance procedures do you follow to keep the tubing machine in optimal condition?

- Perform regular cleaning and inspection of the machine’s components.

- Lubricate moving parts to reduce wear and ensure smooth operation.

- Check for any loose connections or worn-out parts and replace them promptly.

- Monitor the machine’s sensors and gauges to detect any potential issues early on.

- Follow the manufacturer’s recommended maintenance schedule.

4. Describe your understanding of the different types of tubing materials and their properties?

- Steel: Strong, durable, and resistant to corrosion. Used in applications requiring high strength and pressure resistance.

- Stainless Steel: More corrosion-resistant than steel. Ideal for applications involving food, medical, or chemical processes.

- Copper: Excellent electrical and thermal conductivity. Used in electrical wiring, plumbing, and refrigeration.

- Aluminum: Lightweight, strong, and corrosion-resistant. Used in aerospace, automotive, and construction industries.

- Plastic: Versatile, flexible, and resistant to chemicals. Used in a wide range of applications, including fluid handling, packaging, and construction.

5. How do you handle unexpected machine breakdowns or production issues?

- Stay Calm and Assess: Remain calm and assess the situation to identify the root cause of the problem.

- Consult Documentation: Refer to the machine’s user manual or troubleshoot guide for potential solutions.

- Contact Maintenance: If the issue is beyond my expertise, I promptly contact the maintenance team for assistance.

- Isolate and Repair: Isolate the affected area and focus on repairing or replacing the faulty component.

- Test and Resume: Once the repair is complete, I thoroughly test the machine to ensure it is operating correctly before resuming production.

6. Explain the importance of safety protocols in tubing machine operation?

- Protect Operators: Ensure the safety of personnel by preventing injuries from moving machinery, sharp edges, or hazardous materials.

- Prevent Machine Damage: Minimize the risk of damage to the machine caused by improper operation or handling.

- Maintain Production Quality: Create a safe work environment that fosters focus and reduces errors, leading to consistent product quality.

- Reduce Liability: Adhering to safety protocols helps the company mitigate potential legal or financial consequences of workplace incidents.

- Meet Regulatory Compliance: Comply with industry regulations and standards related to machinery safety and operator protection.

7. Describe your experience in working with different tube sizes and dimensions?

- I have worked with a variety of tube sizes, ranging from small-diameter medical tubing to large-scale industrial pipes.

- I am proficient in adjusting the machine’s settings and tooling to accommodate different dimensions.

- I have a strong understanding of tolerances and specifications for various tube applications.

- I ensure that the machine consistently produces tubing that meets the required dimensions and quality standards.

8. How do you ensure that the tubing machine is calibrated accurately?

- Regular Calibration: Conduct regular calibration checks using certified measuring instruments.

- Calibration Procedures: Follow established calibration procedures to ensure accuracy and consistency.

- Reference Standards: Use traceable reference standards to ensure measurements are accurate.

- Verification: Verify the calibration results and make necessary adjustments.

- Documentation: Keep detailed records of calibration activities for quality assurance purposes.

9. Can you explain the role of tooling in the tubing machine’s operation?

- Tooling Selection: Select appropriate tooling based on the tube size, material, and production requirements.

- Tooling Maintenance: Regularly clean, inspect, and replace tooling to ensure optimal performance.

- Tooling Alignment: Ensure proper alignment of tooling to prevent defects or damage to the tubing.

- Tooling Optimization: Optimize tooling settings to maximize production efficiency and minimize waste.

- Tooling Troubleshooting: Identify and resolve any issues related to tooling to maintain smooth machine operation.

10. How do you manage and minimize scrap in tubing production?

- Process Optimization: Optimize the machine’s settings and tooling to reduce waste during the production process.

- Tooling Maintenance: Ensure proper maintenance of tooling to prevent defects or damage to the tubing.

- Raw Material Quality: Inspect raw materials to identify and reject any defective pieces before production.

- Operator Training: Provide thorough training to operators on proper machine operation to reduce errors and waste.

- Scrap Management: Implement a proper scrap management system to recycle or dispose of waste materials responsibly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tubing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tubing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tubing Machine Tender is a highly skilled individual responsible for operating and maintaining automated tubing machines. The primary objective of the role is to ensure the production of high-quality tubular products by operating, adjusting, and troubleshooting machines according to established specifications, procedures, and quality standards.

1. Machine Operation and Maintenance

Operate automated tubing machines, such as bending, cutting, flaring, and welding machines, to produce tubular components.

- Set up machines, load materials, and adjust machine parameters according to engineering drawings and specifications.

- Monitor machine operations, make necessary adjustments to ensure accurate and efficient production, and identify and resolve any issues promptly.

- Perform routine maintenance tasks on machines, such as cleaning, lubricating, and replacing worn parts, to maintain optimal performance.

2. Quality Assurance

Inspect tubular products during and after production to ensure they meet the required quality standards.

- Check dimensions, tolerances, and surface finish using measuring tools and gauges.

- Identify and sort defective products and initiate corrective actions.

- Maintain documentation related to quality inspections and corrective actions.

3. Production Planning and Scheduling

Plan and schedule production activities based on customer orders and production requirements.

- Review production orders and determine the required materials, machines, and tooling.

- Schedule production runs to optimize efficiency and minimize downtime.

- Coordinate with other departments, such as engineering and procurement, to ensure smooth production flow.

4. Continuous Improvement

Identify areas for improvement and implement measures to enhance production efficiency and quality.

- Analyze production data and identify bottlenecks or areas for optimization.

- Propose and implement process improvements to reduce waste, increase productivity, and improve quality.

- Stay updated with the latest industry trends and technologies related to tubing manufacturing.

Interview Tips

To ace the interview for a Tubing Machine Tender position, it’s essential to prepare thoroughly, demonstrate your skills and experience, and convey your enthusiasm for the role.

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing. Research the specific role you’re applying for and understand the key responsibilities and expectations.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in tubing machine operation, quality assurance, and production planning. Provide specific examples of your accomplishments and quantify your results whenever possible.

3. Show Your Passion for Tubing Manufacturing

Express your interest in the tubing manufacturing industry and your desire to contribute to the company’s success. Discuss your understanding of the principles of tubing production and how you can apply your knowledge to the role.

4. Ask Thoughtful Questions

Prepare intelligent questions to ask the interviewer that demonstrate your interest in the position and the company. This shows that you’re engaged and eager to learn more about the opportunity.

5. Practice Your Interview Answers

Rehearse your answers to common interview questions related to your skills, experience, and motivation. Practice with a friend or family member to get feedback and improve your delivery.

6. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving for your interview on time. Punctuality and a polished appearance demonstrate respect for the interviewer and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tubing Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.