Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tubing Oiler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

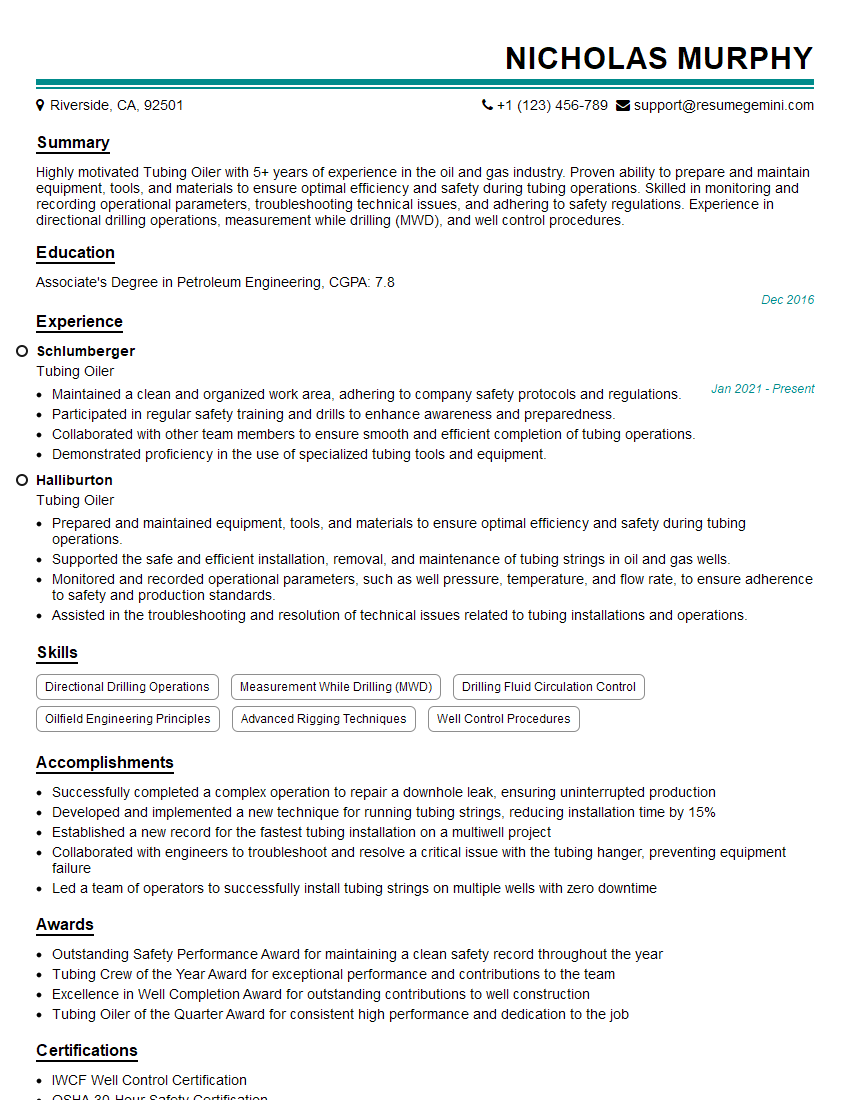

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tubing Oiler

1. What is the role of a Tubing Oiler?

The primary role of a Tubing Oiler is to maintain and operate tubing and pumping systems essential for oil and gas production. I am responsible for monitoring and lubricating tubing and associated components to ensure efficient and safe operations.

2. Describe the different types of tubing you have worked with.

Carbon Steel Tubing

- Strong and durable, used in high-pressure and high-temperature applications

- Prone to corrosion, requires regular inspection and maintenance

Alloy Steel Tubing

- Corrosion-resistant, suitable for harsh environments

- More expensive than carbon steel tubing

3. What is the purpose of a stuffing box in a tubing system?

A stuffing box is a mechanical seal used to prevent leakage of fluid or gas around a rotating shaft or rod. In a tubing system, it creates a tight seal between the tubing and the wellhead to prevent fluid loss from the annulus.

4. Explain the process of tubing pickup.

- Ensure the tubing is properly racked and aligned

- Use a pickup tool to engage the tubing thread

- Lift the tubing and align it with the wellhead

- Tighten the tubing connection to the wellhead

5. What safety precautions should be observed when handling tubing?

- Wear appropriate PPE (hard hat, gloves, safety glasses)

- Inspect tubing for damage before handling

- Use lifting equipment to move heavy tubing

- Follow established safety protocols for working with oilfield equipment

6. How do you troubleshoot tubing leaks?

- Check the stuffing box for leaks and tighten if necessary

- Inspect the tubing for damage or corrosion

- Check the connection between the tubing and the wellhead

- Contact a qualified technician if the leak persists

7. What is the purpose of tubing centralizers?

Tubing centralizers are used to keep the tubing centered in the wellbore. This helps to reduce wear on the tubing and casing, and improves fluid flow.

8. What are the different types of tubing hangers?

- Slip-type hangers

- Hydraulic-set hangers

- Mechanical-set hangers

9. Explain the importance of proper tubing installation.

- Ensures efficient fluid flow

- Reduces the risk of leaks and failures

- Extends the lifespan of tubing and associated components

10. How do you maintain a tubing system?

- Regular inspections for leaks and damage

- Lubrication of moving parts

- Monitoring of fluid levels and temperatures

- Prompt repairs and replacements as needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tubing Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tubing Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tubing Oilers are primarily responsible for maintaining and repairing oil wells, ensuring their efficient and safe operation. Their key responsibilities include:

1. Tubing Installation and Maintenance

Operate tubing tongs and powered equipment to install and remove tubing from oil wells.

- Inspect tubing and casing for defects and wear.

- Maintain tubing components, such as couplings, pup joints, and thread protectors.

2. Wellhead Maintenance

Maintain wellhead equipment, including valves, flanges, and seals.

- Lubricate and test wellhead components to ensure proper operation.

- Inspect and replace wellhead gaskets and seals to prevent leaks.

3. Oil Flow Control

Monitor and control oil flow from wells to ensure optimal production.

- Operate valves and chokes to adjust flow rates.

- Monitor wellhead pressure and temperature gauges to determine well performance.

4. HSE Compliance and Safety Procedures

Adhere to health, safety, and environmental (HSE) regulations and protocols.

- Wear appropriate personal protective equipment (PPE).

- Follow safety procedures when working at well sites.

Interview Tips

To ace an interview for a Tubing Oiler position, candidates should prepare thoroughly and highlight their skills and experience. Here are some key tips:

1. Research the Company and Job

Familiarize yourself with the oil company, its operations, and the specific job requirements. This knowledge will demonstrate your interest and engagement.

- Visit the company website and LinkedIn page.

- Review industry news and reports related to oil and gas production.

2. Highlight Relevant Skills and Experience

Emphasize your experience in tubing installation and maintenance, wellhead maintenance, and oil flow control. Provide specific examples of your work and quantify your accomplishments. Use keywords from the job description in your responses.

- Quantify your experience in tubing installation and removal.

- Describe your expertise in wellhead maintenance and troubleshooting.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. This includes questions about your technical skills, safety knowledge, and teamwork experience.

- Example question: Describe your experience with tubing inspection and maintenance.

- Example answer: “I have experience visually inspecting tubing for corrosion, cracks, and damage. I also use non-destructive testing techniques to identify potential problems.”

4. Emphasize Safety and Compliance

Health, safety, and environmental compliance are paramount in oil and gas operations. Highlight your understanding of HSE regulations and your commitment to safety protocols.

- Explain your experience working with hazardous materials.

- Describe your role in implementing safety measures at work.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive and enthusiastic attitude. Demonstrate your willingness to learn and your passion for the oil and gas industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tubing Oiler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!