Are you gearing up for an interview for a Tufting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tufting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

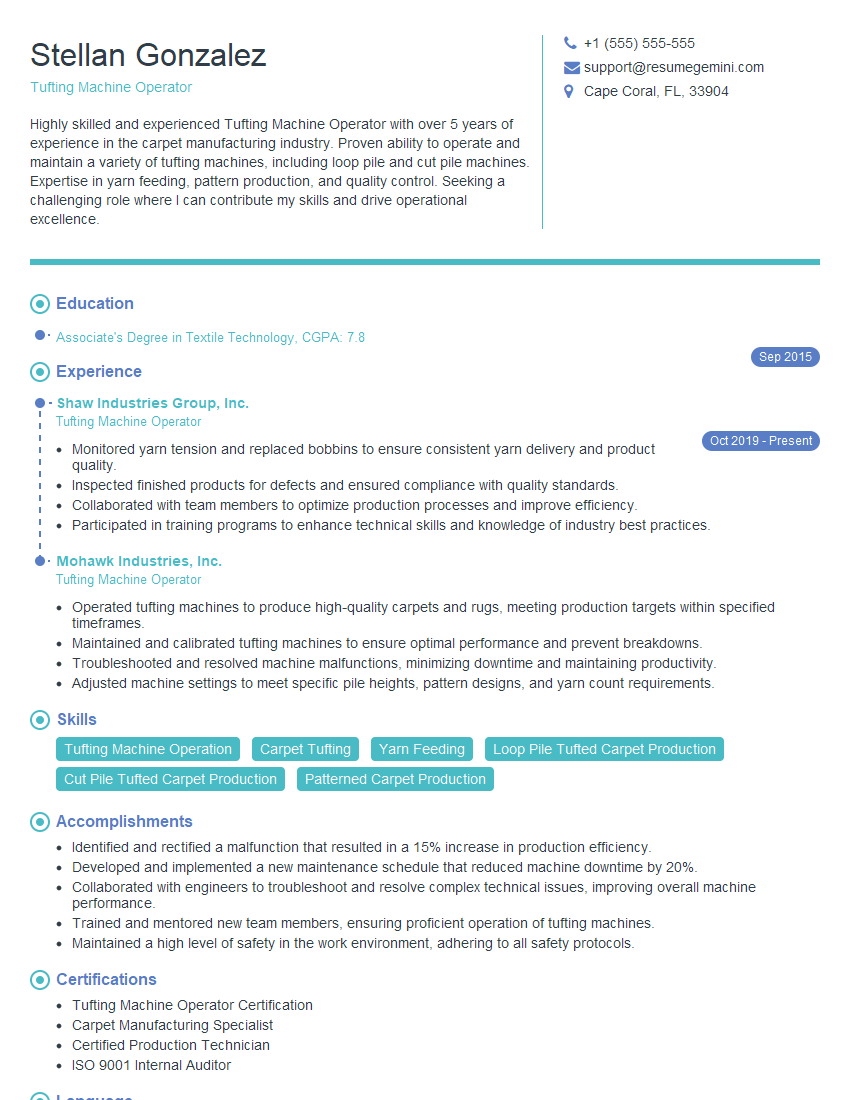

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tufting Machine Operator

1. What are the key responsibilities of a Tufting Machine Operator?

As a highly skilled Tufting Machine Operator, I am responsible for:

- Operating and maintaining tufting machines to produce high-quality tufted products.

- Inspecting and adjusting machines to ensure optimal performance and prevent breakdowns.

- Threading machines and loading yarn into the machine

- Adjusting machine settings and speed to achieve the desired product quality.

- Monitoring production and maintaining records to ensure efficiency.

- Performing routine maintenance and troubleshooting to prevent issues.

2. Describe the different types of tufting machines and their applications.

Manual Tufting Machines

- Suitable for small-scale production and customization.

- Operated manually, allowing for greater control over the tufting process.

Semi-Automatic Tufting Machines

- Combine manual and automated processes.

- Faster than manual machines, but still require human input for complex patterns.

Fully Automated Tufting Machines

- Designed for high-volume production.

- Controlled by computer software, allowing for precise tufting and complex designs.

Specialty Tufting Machines

- Used for specific applications, such as carpet, upholstery, or automotive interiors.

- Equipped with specialized features to meet the unique requirements of the industry.

3. Explain the process of threading a tufting machine.

Threading a tufting machine involves the following steps:

- Prepare the yarn by winding it onto bobbins or cones.

- Load the bobbins or cones onto the yarn racks.

- Thread the yarn through the tensioner and guide it through the machine.

- Insert the needles into the yarn path and ensure they are properly aligned.

- Tighten the needles and adjust the tension to achieve the desired yarn tension.

4. How do you calibrate a tufting machine to ensure accurate tufting?

Calibrating a tufting machine involves the following steps:

- Set the stitch length and pile height according to the product specifications.

- Adjust the machine speed to achieve optimal tufting density.

- Run test samples and measure the pile height, stitch length, and density.

- Make fine adjustments to the machine settings until the desired results are achieved.

- Document the calibration settings for future reference.

5. What are the common problems that can occur during tufting and how do you troubleshoot them?

Common problems include:

- Yarn breakage: Check yarn tension, bobbin alignment, and needle condition.

- Skipped stitches: Inspect needles for damage or misalignment, and adjust machine settings.

- Uneven pile height: Calibrate machine settings, check needle spacing, and adjust yarn tension.

- Fabric puckering: Adjust machine speed and tension settings, and check fabric backing for tightness.

- Machine overheating: Check motor and bearings for wear or lack of lubrication, and improve ventilation.

6. What safety precautions should be taken when operating a tufting machine?

Safety precautions include:

- Wear appropriate protective gear, such as safety glasses, gloves, and hearing protection.

- Keep the work area clean and free of obstacles.

- Lock out and tag the machine before performing maintenance or repairs.

- Never touch moving parts while the machine is in operation.

- Be aware of the location of emergency stop buttons.

7. How do you maintain a tufting machine to ensure optimal performance and longevity?

Maintenance includes:

- Regular cleaning and lubrication of all moving parts.

- Inspection and replacement of worn needles and other components.

- Checking and adjusting yarn tension and machine settings.

- Monitoring machine temperature and ventilation.

- Keeping a maintenance log to track repairs and replacements.

8. Describe your experience in using different types of tufting machines.

I have experience operating both manual and automated tufting machines, including:

- Manual Tufting Machine: Used for small-scale production and intricate designs.

- Semi-Automatic Tufting Machine: Operated with a foot pedal, allowing for faster production while maintaining precision.

- Fully Automated Tufting Machine: Controlled by computer software, capable of producing complex patterns and high volumes.

9. How do you handle working in a fast-paced production environment?

In a fast-paced production environment, I maintain productivity while ensuring accuracy by:

- Prioritizing tasks and managing time effectively.

- Working efficiently and minimizing distractions.

- Communicating effectively with team members and supervisors.

- Taking short breaks to maintain focus and prevent burnout.

- Staying updated on new techniques and technologies to improve productivity.

10. How do you stay updated on the latest advancements in tufting technology?

To stay updated, I:

- Attend industry conferences and exhibitions.

- Subscribe to trade publications and online resources.

- Network with other professionals in the field.

- Participate in online forums and discussions.

- Research new technologies and their applications through online research and experimentation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tufting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tufting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tufting Machine Operator is responsible for operating and maintaining a tufting machine used to manufacture carpets, rugs, and other tufted products. The primary duties include:

1. Machine Operation

intro paragraph

- Set up, operate, and maintain tufting machines to produce textiles according to specifications.

- Monitor machines during operation, ensuring proper functioning and identifying any issues.

2. Quality Control

intro paragraph

- Inspect tufted products for quality, identifying and correcting any defects.

- Maintain records of production and quality control data.

3. Maintenance and Repair

intro paragraph

- Perform routine maintenance on tufting machines, including cleaning, lubrication, and adjustments.

- Troubleshoot and repair minor machine malfunctions.

4. Production Optimization

intro paragraph

- Monitor production rates and identify areas for improvement.

- Suggest and implement process enhancements to increase efficiency and reduce waste.

Interview Tips

To ace an interview for a Tufting Machine Operator position, candidates should:

1. Research the Company and Position

intro paragraph

- Learn about the company’s history, products, and values.

- Review the job description thoroughly to understand the specific requirements and responsibilities.

2. Highlight Relevant Experience and Skills

intro paragraph

- Emphasize previous experience operating tufting machines or similar equipment.

- Showcase expertise in quality control, maintenance, and troubleshooting.

3. Demonstrate Attention to Detail

intro paragraph

- Provide examples of situations where you identified and corrected quality issues.

- Explain how you ensure accuracy and precision in your work.

4. Emphasize Problem-Solving Abilities

intro paragraph

- Discuss instances where you successfully diagnosed and resolved machine malfunctions.

- Highlight your analytical skills and ability to think quickly and creatively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tufting Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tufting Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.