Are you gearing up for a career in Tumbler Machine Operator Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tumbler Machine Operator Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

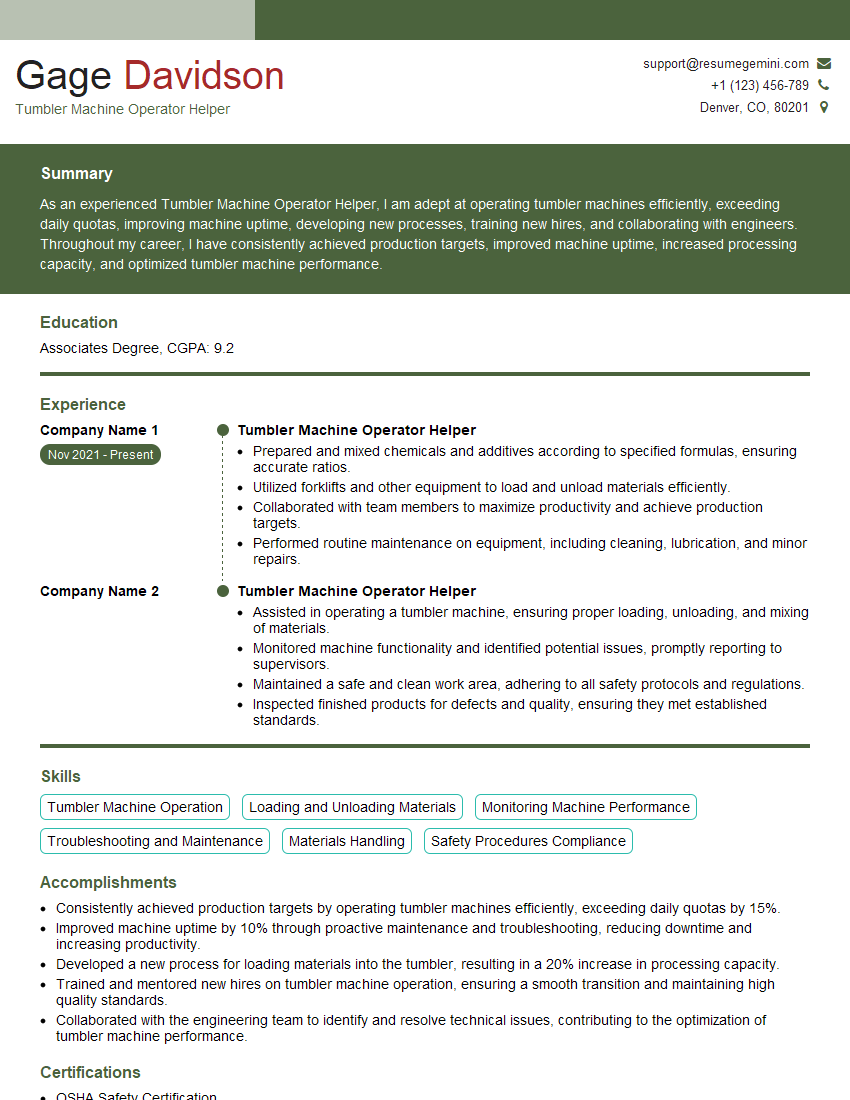

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tumbler Machine Operator Helper

1. Describe the steps involved in loading a tumbler machine with parts?

Answer:

- Ensure the machine is in good working condition.

- Gather the necessary parts and materials.

- Wear appropriate personal protective equipment (PPE).

- Load the parts into the machine according to the specified loading pattern.

- Secure the parts properly to prevent movement during tumbling.

- Follow the manufacturer’s instructions for loading and operating the machine.

2. Explain how to monitor the progress of a tumbling cycle and identify potential issues?

: Monitoring the Tumbling Cycle

- Observe the machine’s operation visually and aurally.

- Check the temperature and pressure gauges regularly.

- Listen for any unusual noises or vibrations.

- Monitor the time remaining in the cycle.

Subheading: Identifying Potential Issues

- Excessively loud noise or vibration could indicate a problem with the machine or parts.

- Abrupt changes in temperature or pressure could indicate a mechanical issue or contamination.

- Uneven tumbling or excessive movement could indicate improper loading or an unbalanced machine.

- Any deviations from normal operating parameters should be investigated promptly.

3. Describe the procedure for unloading a tumbler machine and inspecting the parts?

Answer:

- Wear appropriate PPE and ensure the machine is powered off.

- Open the machine’s door carefully and remove the parts.

- Inspect the parts for any damage, defects, or contamination.

- Segregate damaged or defective parts for further investigation.

- Clean and inspect the machine before reloading.

4. Explain the importance of maintaining a clean and organized work area for tumbler machine operation?

Answer:

- Prevents contamination of parts and materials.

- Reduces the risk of accidents due to tripping hazards or clutter.

- Improves efficiency and productivity by reducing search time.

- Maintains a professional and safe working environment.

- Facilitates compliance with safety regulations and industry standards.

5. Describe the steps involved in troubleshooting a tumbler machine malfunction?

Answer:

- Identify the specific problem by observing the machine’s operation and error codes.

- Check for loose connections, leaks, or damaged components.

- Consult the machine’s manual for troubleshooting procedures.

- Follow the manufacturer’s recommended steps for resolving the issue.

- If the problem persists, contact the manufacturer’s support team for assistance.

6. Explain the importance of following safety procedures when operating a tumbler machine?

Answer:

- Prevents accidents and injuries to operators and others in the vicinity.

- Protects the equipment from damage or malfunction.

- Ensures compliance with industry regulations and company policies.

- Creates a safe and healthy work environment.

- Reduces the risk of downtime and lost productivity due to accidents or equipment failure.

7. Describe the different types of abrasive media used in tumbling machines and their applications?

Answer:

- Ceramic Media:** Durable, fast-cutting, and suitable for a wide range of materials (e.g., metal, ceramics, plastics).

- Plastic Media:** Gentler, less abrasive, ideal for delicate surfaces and polishing (e.g., jewelry, glass).

- Metallic Media:** High-strength, used for deburring and edge breaking (e.g., metal parts, castings).

- Natural Media:** Organic materials (e.g., corn cobs, walnut shells) used for burnishing and surface smoothing.

8. Explain the factors that affect the tumbling process and the desired outcome?

Answer:

- Type of Parts:** Material, shape, size, and quantity.

- Abrasive Media:** Type, size, and shape.

- Cycle Time:** Duration of the tumbling process.

- Speed and Motion:** Rotation speed and tumbling pattern.

- Lubricants and Compounds:** Used to reduce friction and enhance surface quality.

9. Describe the role of a tumbler machine operator helper in supporting the production process?

Answer:

- Loading and unloading machines.

- Monitoring the tumbling process.

- Inspecting parts.

- Maintaining a clean and organized work area.

- Assisting with troubleshooting and repairs.

- Following safety procedures.

- Communicating with supervisors and operators.

10. Explain how you would handle a situation where you notice a potential safety hazard with the tumbler machine?

Answer:

- Identify the hazard and assess its severity.

- Notify the supervisor immediately.

- Take steps to mitigate the risk (e.g., stop the machine, isolate the hazard).

- Cooperate with the investigation and corrective actions.

- Follow established safety protocols and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tumbler Machine Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tumbler Machine Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tumbler Machine Operator Helpers are responsible for a diverse range of tasks that ensure the smooth operation of tumbling machines in a manufacturing setting. Their primary duties include:

1. Material Handling

Loading and unloading workpieces, materials, and abrasives into the tumbling machine.

- Inspecting workpieces to identify any potential defects before processing.

- Following prescribed loading procedures to ensure optimal results.

2. Machine Operation

Monitoring the operation of the tumbling machine, including adjusting settings such as speed, duration, and abrasive type.

- Ensuring machine parameters are set according to process specifications.

- Identifying and resolving any operational issues promptly to minimize downtime.

3. Quality Control

Inspecting processed workpieces to assess their quality and ensuring they meet established standards.

- Using gauges, calipers, or other measuring tools to verify workpiece dimensions and tolerances.

- Identifying non-conforming parts and segregating them accordingly.

4. Maintenance and Cleaning

Performing routine maintenance tasks, such as cleaning and lubricating the tumbling machine and its components.

- Following established maintenance schedules to ensure proper machine operation.

- Replacing worn parts and making minor repairs as necessary.

5. Safety and Compliance

Adhering to safety regulations and operating procedures to ensure a safe work environment.

- Wearing appropriate personal protective equipment (PPE).

- Following established lockout/tagout procedures during maintenance.

Interview Tips

To prepare for an interview for a Tumbler Machine Operator Helper position, it’s essential to thoroughly review the job description and key responsibilities to gain a clear understanding of the role.

1. Research the Company and Industry

Research the company’s website, industry publications, and online forums to understand its business, products, and competitive landscape.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice answering questions about your technical abilities, attention to detail, and problem-solving skills.

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your ability to load and unload workpieces, monitor machine operation, inspect processed parts, and maintain equipment.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the position and the company. Ask questions about the company’s growth plans, the team you would be working with, and opportunities for professional development.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally for the interview, arrive on time, and maintain a positive and confident demeanor throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tumbler Machine Operator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tumbler Machine Operator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.