Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tumblers Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

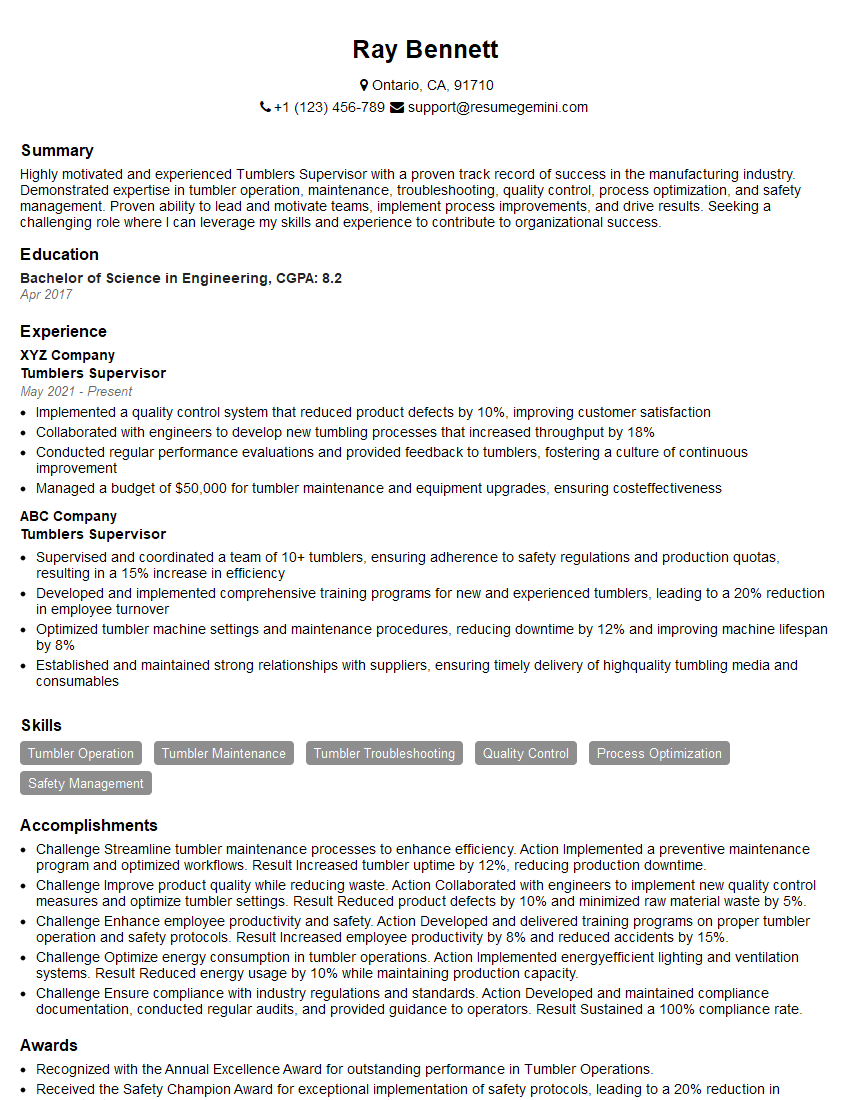

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tumblers Supervisor

1. Describe the key responsibilities of a Tumblers Supervisor.

As a Tumblers Supervisor, my core responsibilities encompass:

- Overseeing the operation of tumbling machines, ensuring efficient processing of materials.

- Monitoring and maintaining equipment, implementing preventive maintenance schedules to minimize downtime.

- Supervising and training team members, ensuring adherence to safety protocols and production standards.

- Coordinating with production planning to optimize scheduling, ensuring timely completion of orders.

- Conducting quality control inspections, verifying that tumbled parts meet specifications and customer requirements.

2. Explain the different types of tumbling processes and their applications.

Abrasive Tumbling

- Uses abrasive media and water to remove material from the surface of workpieces, creating a smooth finish.

- Applications: Deburring, polishing, and shaping metal parts.

Burnishing Tumbling

- Employs steel or ceramic media to smooth and polish surfaces without removing material.

- Applications: Enhancing the appearance and corrosion resistance of jewelry, cutlery, and other metal products.

Vibratory Tumbling

- Utilizes vibrating motion to mix and process materials without tumbling media.

- Applications: Deburring, cleaning, and polishing small parts, such as electronic components and medical devices.

3. How do you optimize tumbling parameters to achieve desired results?

Optimizing tumbling parameters requires considering several factors:

- Media Selection: Choosing the appropriate abrasive or burnishing media based on the desired surface finish and material type.

- Media Load: Determining the optimal ratio of media to workpiece volume to ensure proper coverage and agitation.

- Speed and Duration: Setting appropriate speed and tumbling time to achieve the desired surface finish without over-processing.

- Compound Addition: Using appropriate compounds to enhance the tumbling process, such as detergents for cleaning or polishing agents for burnishing.

- Monitoring and Adjustment: Regularly checking the progress and making adjustments based on visual inspections and quality control measurements.

4. How do you troubleshoot common issues that arise during tumbling processes?

Troubleshooting common tumbling issues involves:

- Excessive Wear or Breakage: Identifying the cause, such as incorrect media selection, overloading, or improper speed settings.

- Insufficient Surface Finish: Analyzing factors like media contamination, inadequate compound usage, or short tumbling duration.

- Noise or Vibration: Checking for equipment imbalances, loose components, or worn bearings.

- Media Contamination: Implementing measures to prevent cross-contamination between different tumbling processes.

- Safety Concerns: Enforcing safety protocols and addressing any potential hazards, such as excessive dust or chemical exposure.

5. How do you ensure the quality of tumbled parts?

Quality assurance in tumbling processes involves:

- Visual Inspection: Examining parts for surface defects, scratches, or discoloration.

- Dimensional Measurement: Verifying that tumbled parts meet specified dimensions using appropriate measuring equipment.

- Surface Roughness Testing: Using surface roughness testers to assess the smoothness and consistency of the finish.

- Hardness Testing: Implementing hardness testing methods to ensure that tumbling has not compromised the material’s integrity.

- Customer Feedback: Gathering feedback from customers to identify any quality concerns and make necessary improvements.

6. How do you maintain a safe and efficient tumbling operation?

Maintaining a safe and efficient tumbling operation requires:

- Adhering to Safety Protocols: Enforcing proper PPE usage, lockout/tagout procedures, and spill containment measures.

- Regular Equipment Maintenance: Implementing preventive maintenance schedules, inspecting equipment regularly, and addressing any potential issues promptly.

- Proper Loading and Unloading: Ensuring that tumbling machines are loaded and unloaded safely, avoiding overloading or underloading conditions.

- Environmental Control: Managing dust and noise levels, providing proper ventilation, and disposing of waste materials responsibly.

- Training and Supervision: Providing comprehensive training to staff on safety procedures, equipment operation, and quality control measures.

7. How do you manage a team of tumbling operators?

Effective team management as a Tumblers Supervisor involves:

- Communication: Establishing clear communication channels, providing regular updates, and fostering open dialogue.

- Training and Development: Training team members on proper tumbling techniques, safety protocols, and quality standards.

- Performance Monitoring: Tracking performance metrics, providing feedback, and implementing performance improvement plans when necessary.

- Motivation and Recognition: Recognizing and rewarding team members for their contributions and achievements.

- Teamwork and Collaboration: Promoting a collaborative work environment and encouraging team members to support each other.

8. How do you stay up-to-date with the latest advancements in tumbling technology?

Staying current with industry advancements involves:

- Attending Conferences and Trade Shows: Participating in industry events to learn about new technologies and best practices.

- Reading Trade Publications and Journals: Subscribing to industry publications to access technical articles and research papers.

- Networking with Peers: Connecting with other tumbling professionals to exchange knowledge and insights.

- Collaborating with Equipment Manufacturers: Partnering with equipment suppliers to gain information about new developments and product innovations.

- Continuous Learning: Pursuing additional training programs, online courses, or certification to enhance knowledge and skills.

9. How do you prioritize tasks and manage your time effectively as a Tumblers Supervisor?

Prioritizing tasks and time management involves:

- Establishing Clear Priorities: Identifying the most important tasks and focusing on completing them first.

- Time Management Techniques: Using tools like to-do lists, calendars, and scheduling software to plan and track time.

- Delegation: Delegating appropriate tasks to team members to optimize productivity.

- Avoiding Distractions: Minimizing interruptions and distractions to maintain focus and efficiency.

- Regular Reviews: Regularly assessing progress, making adjustments, and evaluating the effectiveness of time management strategies.

10. What sets you apart from other candidates for this role and makes you the ideal Tumblers Supervisor?

My unique combination of skills and experience positions me as the ideal candidate for this role due to:

- Tumbling Expertise: Proven track record of successfully managing tumbling operations, optimizing processes, and troubleshooting issues.

- Team Leadership: Demonstrated ability to motivate, train, and manage a team of tumbling operators, while fostering a positive and productive work environment.

- Quality Assurance: Strong focus on quality control, ensuring that tumbled parts meet specifications and customer requirements.

- Continuous Improvement: Passion for exploring new technologies, implementing process improvements, and enhancing overall tumbling operations.

- Communication and Collaboration: Excellent communication and interpersonal skills, enabling effective collaboration with team members, customers, and stakeholders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tumblers Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tumblers Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tumblers Supervisors are responsible for overseeing the operation of tumbling machines used in various industries for processes such as deburring, polishing, and surface finishing. They ensure the smooth functioning of the tumbling process, maintain equipment, and manage a team of operators.

1. Production Management

Plan and schedule tumbling operations, ensuring optimal production levels and timely completion of orders.

- Determine the correct tumbling parameters for each type of workpiece.

- Monitor production progress and make adjustments as necessary.

2. Quality Control

Inspect workpieces after tumbling to ensure they meet specifications and quality standards.

- Identify and resolve any quality issues that may arise.

- Maintain quality records and documentation.

3. Equipment Maintenance

Conduct routine maintenance and troubleshooting on tumbling machines to prevent breakdowns and ensure optimal performance.

- Lubricate and adjust machine components.

- Identify and replace worn or damaged parts.

4. Team Management

Supervise and support a team of tumbling operators, providing guidance and training as needed.

- Assign tasks and monitor operator performance.

- Ensure operators follow safety protocols and operate equipment correctly.

Interview Tips

Preparing for an interview for a Tumblers Supervisor position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to learn about the company, its industry, and the specific job responsibilities of a Tumblers Supervisor. This shows the interviewer that you have a genuine interest in the opportunity.

- Visit the company’s website and LinkedIn page.

- Review the job description thoroughly.

2. Highlight Your Technical Expertise

During the interview, emphasize your technical knowledge and experience in tumbling operations. Use specific examples to demonstrate your ability to plan, execute, and troubleshoot tumbling processes.

- Describe your experience in setting up and operating different types of tumbling machines.

- Share examples of how you have improved production efficiency or resolved quality issues.

3. Showcase Your Leadership and Communication Skills

Tumblers Supervisors are responsible for leading and motivating a team of operators. Highlight your leadership and communication skills during the interview by providing examples of how you have effectively managed a team and resolved conflicts.

- Describe your experience in training and mentoring operators.

- Provide examples of how you have communicated effectively with operators, supervisors, and other stakeholders.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to tumbling operations, quality control, and team management. Anticipating these questions will help you provide confident and insightful responses.

- “Tell me about your experience in setting up and operating tumbling machines for different types of workpieces.”

- “Describe a time when you encountered a quality issue during tumbling and how you resolved it.”

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the role and the company. This shows the interviewer that you are engaged and genuinely interested in the opportunity.

- “What are the key challenges and growth opportunities in this role?”

- “How does the company invest in the professional development of its employees?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tumblers Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!