Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tungsten Refiner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

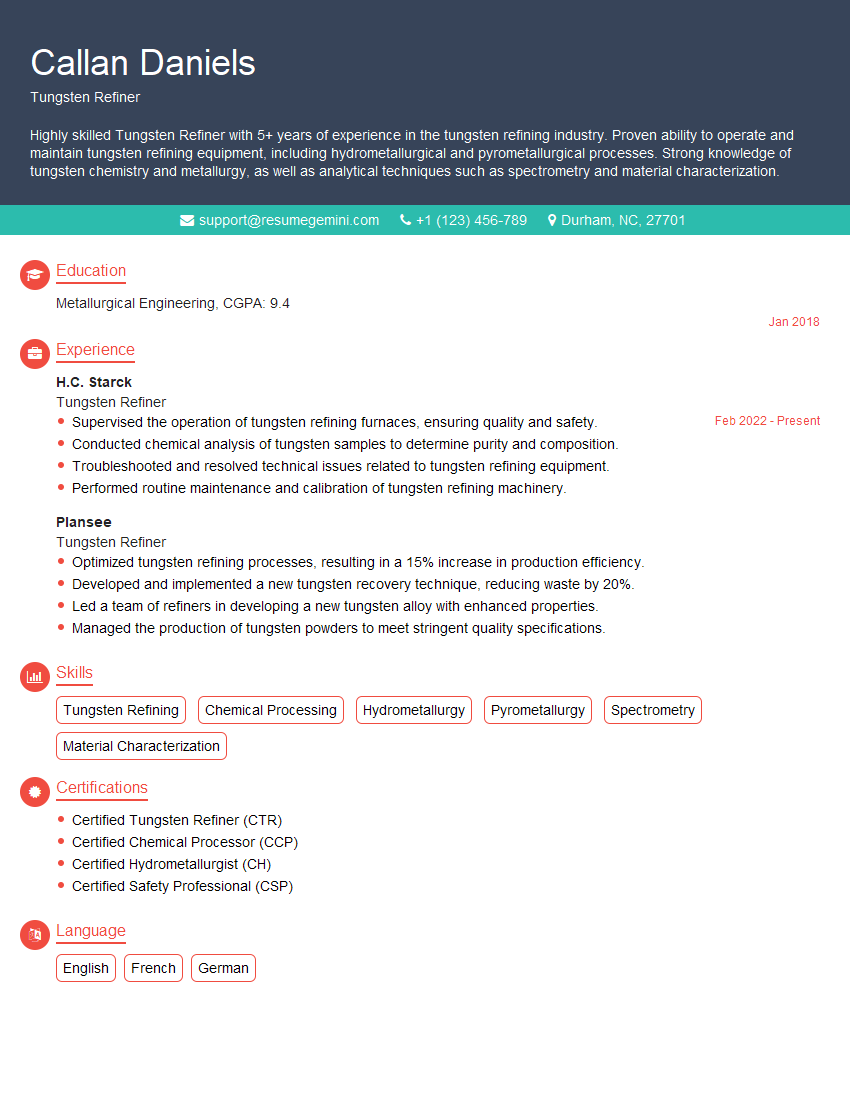

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tungsten Refiner

1. Explain the chemical composition and properties of tungsten?

- Tungsten (W) is a hard, heavy, and brittle metal.

- It has a melting point of 3,410 °C (6,170 °F) and a boiling point of 5,660 °C (10,220 °F).

- Tungsten is highly resistant to wear and corrosion.

- It is used in a wide variety of applications, including high-speed cutting tools, wear-resistant coatings, and electrical contacts.

2. Describe the steps involved in the tungsten refining process?

Ore Mining

- Tungsten is mined from wolframite ore.

- Wolframite is a mineral that contains tungsten, iron, and manganese.

Ore Concentration

- The wolframite ore is crushed and ground into a fine powder.

- The powder is then concentrated using a variety of methods, such as gravity separation, magnetic separation, and flotation.

Chemical Processing

- The concentrated wolframite is then chemically processed to remove the iron and manganese impurities.

- This is done using a variety of methods, such as roasting, leaching, and precipitation.

Metal Reduction

- The purified tungsten oxide is then reduced to metal using a variety of methods, such as hydrogen reduction, carbon reduction, and electro-winning.

Refining and Purification

- The tungsten metal is then refined and purified using a variety of methods, such as vacuum arc remelting, electron beam melting, and powder metallurgy.

3. What are the different types of tungsten products?

- Tungsten powder

- Tungsten carbide

- Tungsten rods and wires

- Tungsten sheets and plates

- Tungsten alloys

4. What are the applications of tungsten products?

- Tungsten is used in a wide variety of applications, including:

- High-speed cutting tools

- Wear-resistant coatings

- Electrical contacts

- Heating elements

- Lighting

5. What are the challenges in the tungsten refining process?

- Tungsten is a very hard and brittle metal, which can make it difficult to process.

- Tungsten is also very reactive, which can make it difficult to store and handle.

- The tungsten refining process is often complex and time-consuming.

6. How can the efficiency of the tungsten refining process be improved?

- By using more efficient mining and concentration methods.

- By using more efficient chemical processing methods.

- By using more efficient metal reduction methods.

- By using more efficient refining and purification methods.

7. What are the environmental impacts of the tungsten refining process?

- The tungsten refining process can generate a variety of pollutants, including:

- Air pollution

- Water pollution

- Solid waste

8. How can the environmental impacts of the tungsten refining process be minimized?

- By using more efficient mining and concentration methods.

- By using more efficient chemical processing methods.

- By using more efficient metal reduction methods.

- By using more efficient refining and purification methods.

- By recycling and reusing tungsten products.

9. What are the future trends in the tungsten refining industry?

- The tungsten refining industry is expected to grow in the coming years.

- This is due to the increasing demand for tungsten products in a variety of applications.

- The industry is also expected to see a number of technological advancements in the coming years.

- These advancements will likely focus on improving the efficiency and environmental impact of the tungsten refining process.

10. What are your qualifications for this job?

- I have a bachelor’s degree in chemical engineering.

- I have 5 years of experience in the tungsten refining industry.

- I am familiar with all aspects of the tungsten refining process.

- I am a hard worker and I am always willing to learn new things.

- I am confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tungsten Refiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tungsten Refiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tungsten Refiner is responsible for extracting tungsten from raw materials and purifying it to meet specific standards. Their key job responsibilities include:

1. Tungsten Extraction

Tungsten refiners extract tungsten from various sources, such as ores, minerals, and scrap materials.

- Selecting and preparing raw materials

- Operating heavy machinery and equipment for extraction processes

- Monitoring and adjusting extraction parameters to optimize yield

2. Tungsten Purification

After extraction, refiners purify tungsten to remove impurities and meet industry standards.

- Conducting chemical and physical analysis to determine the quality of extracted tungsten

- Applying various techniques such as precipitation, solvent extraction, and electrolysis to remove impurities

- Ensuring that the final product meets specifications

3. Product Development and Improvement

Refiners may also work on developing new and improved tungsten refining processes.

- Researching emerging technologies and best practices

- Collaborating with engineers and scientists to optimize processes

- Implementing new techniques to improve efficiency and reduce costs

4. Quality Control and Assurance

Refiners play a crucial role in maintaining the quality of tungsten products.

- Conducting regular testing and inspections to ensure product quality meets standards

- Monitoring and controlling production processes to minimize defects

- Documenting and maintaining records of quality control procedures

Interview Tips

To ace your interview for a Tungsten Refiner position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, history, and values. Research the tungsten industry, including market trends, technological advancements, and environmental regulations.

- Visit the company’s website and social media pages

- Read industry publications and news articles

2. Highlight Your Expertise

Emphasize your technical skills and experience in tungsten refining. Showcase your knowledge of extraction, purification, quality control, and process optimization techniques.

- Quantify your accomplishments with specific examples and metrics

- Discuss your research and development experience, if applicable

3. Demonstrate Your Understanding of Tungsten Applications

Tungsten has diverse applications, so be prepared to discuss your understanding of its uses in industries such as aerospace, automotive, and electronics.

- Research the end-use industries for tungsten

- Explain how tungsten’s properties make it suitable for specific applications

4. Show Your Commitment to Safety and Sustainability

Tungsten refining involves hazardous materials and processes. Emphasize your commitment to safety and environmental stewardship.

- Discuss your experience in following safety protocols and regulations

- Explain how you minimize environmental impact in your work

5. Practice and Prepare

Practice answering common interview questions related to your skills, experience, and motivations. Prepare thoughtful questions to ask the interviewer, demonstrating your interest and engagement.

- Use mock interview tools or ask a friend or family member to practice

- Research the interviewer on LinkedIn or the company website

Next Step:

Now that you’re armed with the knowledge of Tungsten Refiner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tungsten Refiner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini