Are you gearing up for a career in Tunnel Kiln Firer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tunnel Kiln Firer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

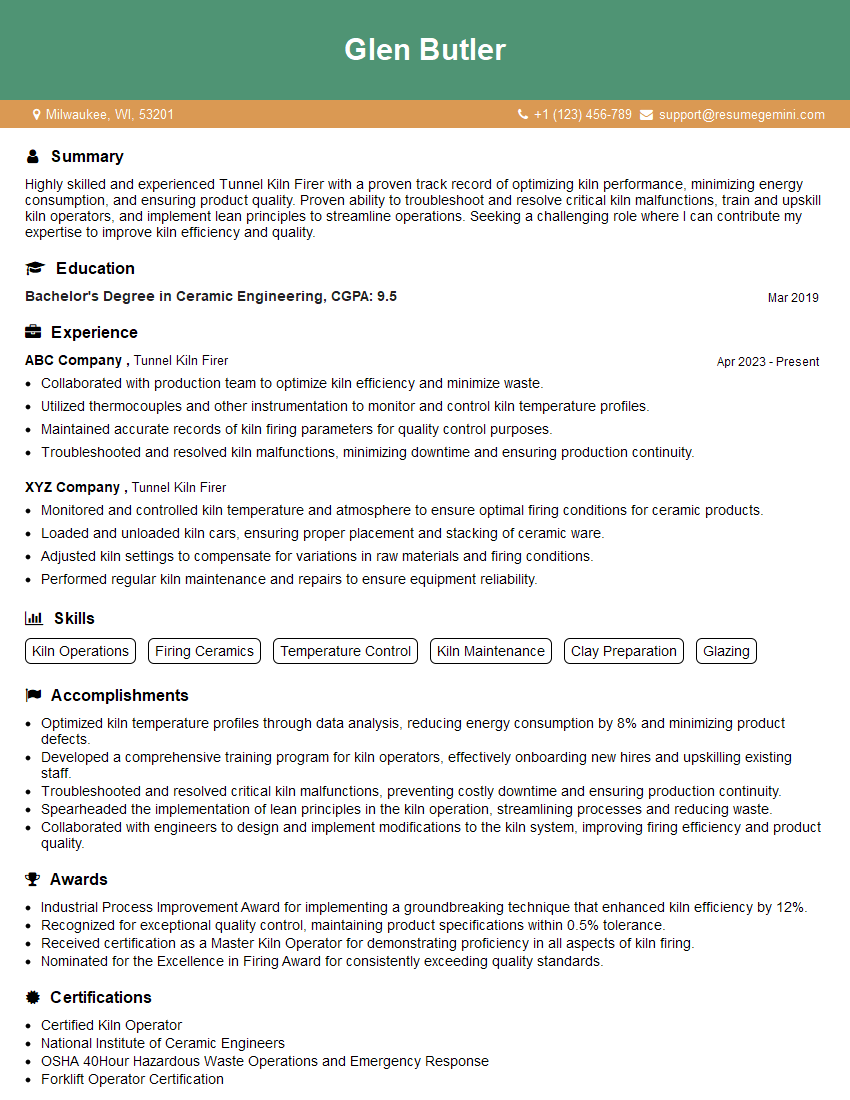

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tunnel Kiln Firer

1. Explain the key responsibilities of a Tunnel Kiln Firer?

A Tunnel Kiln Firer is responsible for:

- Preparing and maintaining the kiln.

- Loading and unloading the kiln with ware.

- Firing the kiln according to a predetermined firing schedule.

- Monitoring the kiln’s temperature and atmosphere.

- Making adjustments to the firing process as needed.

- Ensuring the safety of the kiln and its surroundings.

2. What are the different types of tunnel kilns?

Periodic kilns

- Operated in cycles.

- Heated up, soaked, and cooled down.

Continuous kilns

- Operate continuously.

- Ware is loaded and unloaded while the kiln is running.

3. What are the critical control points in the firing process?

- Temperature.

- Atmosphere.

- Rate of heating and cooling.

4. What are the potential hazards of working with a tunnel kiln?

- Burns.

- Exposure to toxic fumes.

- Explosions.

5. How do you ensure the safety of the kiln and its surroundings?

- Properly training all kiln operators.

- Wearing appropriate safety gear.

- Following all safety procedures.

- Regularly inspecting the kiln and its equipment.

- Maintaining the kiln in good working order.

6. What are the most common problems you encounter as a Tunnel Kiln Firer?

- Temperature fluctuations.

- Atmosphere control issues.

- Equipment malfunctions.

- Warpage of ware.

- Glaze defects.

7. How do you troubleshoot and resolve these problems?

The troubleshooting and resolution of kiln problems depend on the specific issue encountered. However, some general troubleshooting steps include:

- Identifying the problem.

- Determining the cause of the problem.

- Developing a solution.

- Implementing the solution.

- Evaluating the results.

8. What are the qualities of a successful Tunnel Kiln Firer?

- Attention to detail.

- Strong problem-solving skills.

- Good communication skills.

- Ability to work independently and as part of a team.

- Commitment to safety.

9. What is your experience with firing different types of ware?

I have experience firing a variety of ware types, including:

- Earthenware.

- Stoneware.

- Porcelain.

- Glass.

- Metal.

10. What are your career goals?

My career goal is to become a skilled Tunnel Kiln Firer and to contribute to the production of high-quality ceramic products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tunnel Kiln Firer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tunnel Kiln Firer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Tunnel Kiln Firer

Tunnel kiln firers are responsible for operating and monitoring tunnel kilns, which are used to fire ceramic products such as tiles, bricks, and pottery.

1. Loading and Unloading Kilns

Firers load raw materials into the kiln and unload finished products once they have been fired.

- Ensure that kilns are loaded and unloaded safely and efficiently.

- Inspect materials before loading to ensure they meet specifications.

2. Monitoring Kiln Conditions

Firers monitor kiln conditions, such as temperature, atmosphere, and speed, to ensure that the products are fired correctly.

- Monitor kiln temperature and adjust burners to maintain desired firing temperature.

- Control kiln atmosphere to achieve desired product properties.

3. Troubleshooting Kiln Problems

Firers troubleshoot and resolve kiln problems, such as equipment malfunctions and product defects.

- Identify and resolve kiln malfunctions to minimize downtime.

- Analyze product defects and make adjustments to kiln conditions to prevent future defects.

4. Maintaining Kilns

Firers maintain kilns and related equipment to ensure they are in good working order.

- Perform routine maintenance tasks, such as cleaning and lubricating equipment.

- Inspect kilns regularly for wear and tear and make necessary repairs.

Interview Preparation Tips and Hacks for Tunnel Kiln Firer

Interviews can be daunting, but there are a few things you can do to prepare and increase your chances of success.

1. Research the Company and Position

Make sure you know about the company you’re applying to and the position you’re applying for. Research the company’s website, annual reports, news articles and social media pages to get a good understanding of their culture, values and current projects. Review the job description carefully and identify the key requirements for the position. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the opportunity.

2. Practice Your Answers

Once you know what questions you’re likely to be asked, practice your answers. This will help you feel more confident and prepared during the interview. Think about your experiences and accomplishments, and how they relate to the job requirements. Use the STAR method to structure your answers. This means providing a Situation, Task, Action, and Result for each of your examples. Practice answering questions out loud. This will help you get used to the sound of your own voice and make you more comfortable speaking in front of others.

3. Be Yourself

It’s important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic in your answers. Share your passion for the industry and your desire to learn and grow. Show the interviewer that you’re a good fit for the company and the position.

4. Follow Up

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank the interviewer for their time. In your thank-you note, you can also mention any additional information you think would be helpful to the interviewer such as additional relevant experience, skills or qualifications that you may have forgotten to mention during the interview.

Next Step:

Now that you’re armed with the knowledge of Tunnel Kiln Firer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tunnel Kiln Firer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini