Are you gearing up for a career in Tunnel Kiln Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tunnel Kiln Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

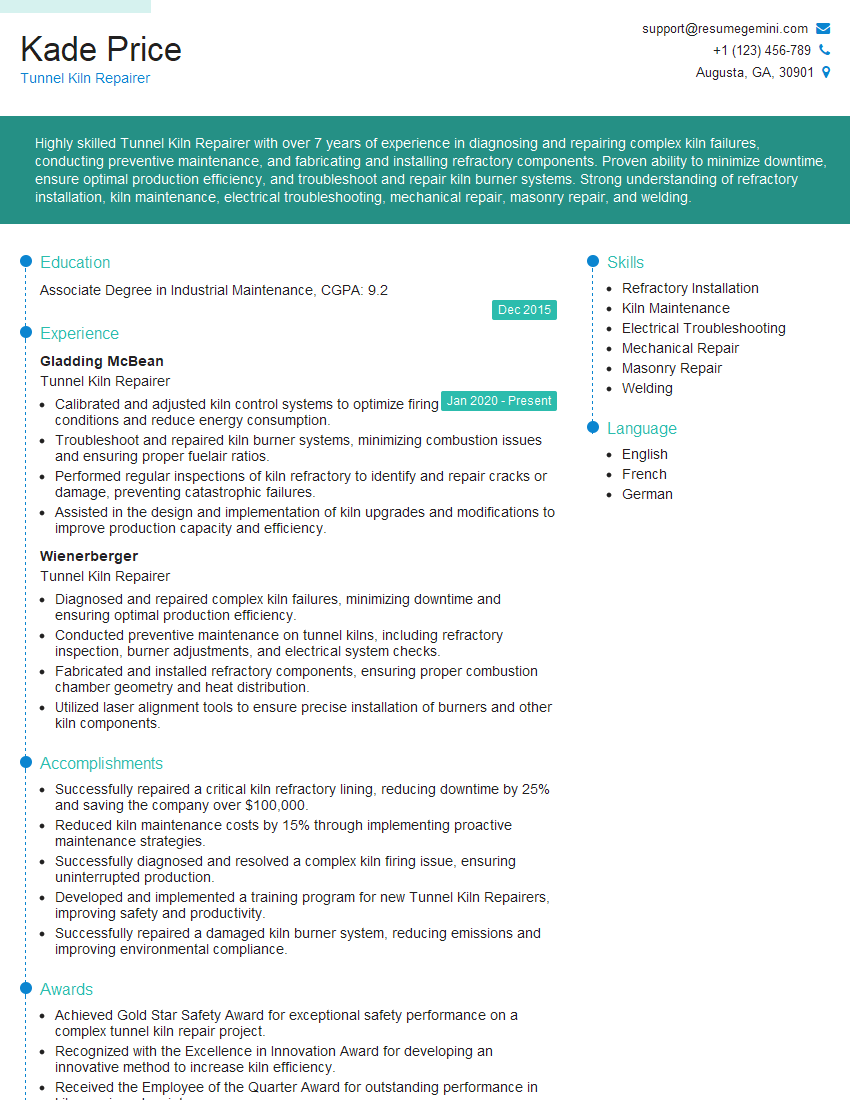

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tunnel Kiln Repairer

1. What are the key components of a tunnel kiln and their functions?

The key components of a tunnel kiln and their functions are as follows:

- Burners: These are used to generate heat inside the kiln.

- Cooling zone: This section is used to cool down the products after they have been fired.

- Curing zone: This section is used to cure the products after they have been cooled down.

- Drying zone: This section is used to dry the products before they are fired.

- Heating zone: This section is used to heat the products before they are fired.

- Loading zone: This section is used to load the products into the kiln.

- Unloading zone: This section is used to unload the products from the kiln.

2. What are the common types of refractories used in tunnel kilns and their properties?

Types of Refractories

- Fireclay refractories: These are made from clay and have a high melting point and good thermal conductivity.

- High-alumina refractories: These are made from alumina and have a high melting point and good resistance to wear and tear.

- Silicon carbide refractories: These are made from silicon carbide and have a high melting point and good resistance to thermal shock.

- Zirconia refractories: These are made from zirconia and have a high melting point and good resistance to corrosion.

Properties of Refractories

- Melting point

- Thermal conductivity

- Resistance to wear and tear

- Resistance to thermal shock

- Corrosion resistance

3. What are the different types of insulation used in tunnel kilns and their advantages and disadvantages?

The different types of insulation used in tunnel kilns and their advantages and disadvantages are as follows:

- Ceramic fiber insulation: This type of insulation is made from ceramic fibers and has a high thermal resistance and low thermal conductivity.

- Mineral wool insulation: This type of insulation is made from mineral wool and has a high thermal resistance and low thermal conductivity.

- Perlite insulation: This type of insulation is made from perlite and has a high thermal resistance and low thermal conductivity.

- Vermiculite insulation: This type of insulation is made from vermiculite and has a high thermal resistance and low thermal conductivity.

4. What are the common causes of cracks in tunnel kiln shells and how can they be prevented?

The common causes of cracks in tunnel kiln shells and how they can be prevented are as follows:

- Thermal expansion: The different parts of the kiln shell expand at different rates when heated, which can cause cracks.

- Mechanical stress: The kiln shell is subjected to mechanical stress from the weight of the kiln and the products being fired, which can cause cracks.

- Corrosion: The kiln shell can be corroded by the gases produced during firing, which can cause cracks.

Cracks in the kiln shell can be prevented by:

- Using a kiln shell made of a material with a low coefficient of thermal expansion.

- Reinforcing the kiln shell with steel beams or rods.

- Protecting the kiln shell from corrosion by applying a protective coating.

5. What are the safety precautions that should be taken when working on a tunnel kiln?

The safety precautions that should be taken when working on a tunnel kiln are as follows:

- Wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Be aware of the hazards associated with working with high temperatures, including burns and heat stroke.

- Do not enter the kiln while it is in operation.

- Be aware of the location of the fire extinguishers and know how to use them.

- Have a clear understanding of the emergency procedures in case of a fire or other accident.

6. What are the key maintenance tasks that should be performed on a tunnel kiln?

The key maintenance tasks that should be performed on a tunnel kiln are as follows:

- Inspect the kiln shell for cracks or other damage.

- Inspect the insulation for damage or deterioration.

- Inspect the burners for proper operation.

- Inspect the temperature control system for proper operation.

- Lubricate the moving parts of the kiln.

- Clean the kiln of any debris.

7. What are the different types of kiln furniture used in tunnel kilns and their applications?

The different types of kiln furniture used in tunnel kilns and their applications are as follows:

- Shelves: These are used to support the products during firing.

- Battens: These are used to separate the products on the shelves.

- Posts: These are used to support the shelves.

- Saggers: These are used to protect the products from the gases produced during firing.

- Caps: These are used to cover the saggers.

8. What are the different types of firing defects that can occur in tunnel kilns and how can they be prevented?

The different types of firing defects that can occur in tunnel kilns and how they can be prevented are as follows:

- Crazing: This is a type of defect that occurs when the glaze on the product cracks.

- Pinholing: This is a type of defect that occurs when small holes appear in the glaze on the product.

- Blistering: This is a type of defect that occurs when bubbles form in the glaze on the product.

- Bloating: This is a type of defect that occurs when the product swells during firing.

- Warping: This is a type of defect that occurs when the product changes shape during firing.

9. What are the energy efficiency measures that can be implemented in tunnel kilns?

The energy efficiency measures that can be implemented in tunnel kilns are as follows:

- Use a kiln with a high thermal efficiency.

- Insulate the kiln properly.

- Use a kiln with a low heat loss.

- Optimize the firing process.

- Use a kiln with a high-efficiency burner.

10. What are the latest trends in tunnel kiln technology?

The latest trends in tunnel kiln technology are as follows:

- The use of advanced control systems to optimize the firing process.

- The use of new materials to improve the thermal efficiency of the kiln.

- The use of new technologies to reduce the emissions from the kiln.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tunnel Kiln Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tunnel Kiln Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tunnel Kiln Repairer is a key member of a team responsible for maintaining and repairing tunnel kilns used in the production of various materials such as bricks, tiles, and ceramics. The primary responsibilities of this role include:

1. Kiln Maintenance and Inspection

Conduct regular inspections of tunnel kilns to identify potential issues and wear and tear.

- Monitor kiln performance and operating parameters to ensure optimal efficiency and productivity.

- Identify and resolve minor kiln issues to prevent escalation into major problems.

2. Kiln Repair and Refurbishment

Perform repairs and maintenance on tunnel kilns, including refractory lining repairs, burner adjustments, and electrical system troubleshooting.

- Conduct major overhauls and refurbishments of kilns during scheduled maintenance periods.

- Use specialized tools and equipment to safely and effectively repair kiln components.

3. Safety and Compliance

Adhere to all safety regulations and procedures related to kiln operations and maintenance.

- Wear appropriate personal protective equipment (PPE) and follow safe work practices.

- Ensure that kilns meet all environmental and regulatory requirements.

4. Troubleshooting and Problem-Solving

Diagnose and troubleshoot kiln malfunctions and equipment issues.

- Analyze kiln data and identify root causes of problems.

- Develop and implement solutions to restore kiln functionality and efficiency.

Interview Tips

Preparing thoroughly for your Tunnel Kiln Repairer interview is crucial to showcasing your skills and qualifications effectively. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and industry standing. Research the specific requirements of the Tunnel Kiln Repairer role and identify how your experience aligns with them.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay updated on the latest technologies and best practices.

2. Highlight Your Technical Skills

Emphasize your proficiency in kiln repair and maintenance techniques. Provide specific examples of your experience in:

- Refractory lining repairs and replacements

- Burner adjustments and troubleshooting

- Electrical system maintenance and repairs

3. Demonstrate Your Problem-Solving Abilities

Interviewers want to know that you can identify and resolve kiln issues effectively. Describe situations where you successfully diagnosed and fixed kiln malfunctions. Use the STAR method (Situation, Task, Action, Result) to structure your answers:

- Start by describing the situation and the kiln issue you encountered.

- Explain the steps you took to analyze the problem and identify the root cause.

- Highlight the actions you implemented to resolve the issue.

- Quantify the results of your actions by stating how the kiln performance improved or how downtime was minimized.

4. Emphasize Safety and Compliance

Tunnel Kiln Repairers must prioritize safety and compliance in their work. Emphasize your commitment to following all safety regulations and procedures. Describe your experience in:

- Wearing appropriate PPE and adhering to safe work practices.

- Ensuring that kilns meet environmental and regulatory requirements.

5. Practice Your Answers

Prepare for common interview questions by practicing your answers out loud. This will help you feel more confident and articulate during the actual interview. Consider using a mock interview tool or asking a friend or family member to conduct a practice session with you.

- Prepare for questions about your technical skills, problem-solving abilities, and experience with kiln maintenance.

- Rehearse your answers to behavioral questions that focus on your teamwork, communication, and safety mindset.

Next Step:

Now that you’re armed with the knowledge of Tunnel Kiln Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tunnel Kiln Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini