Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Turbine Blade Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Turbine Blade Assembler so you can tailor your answers to impress potential employers.

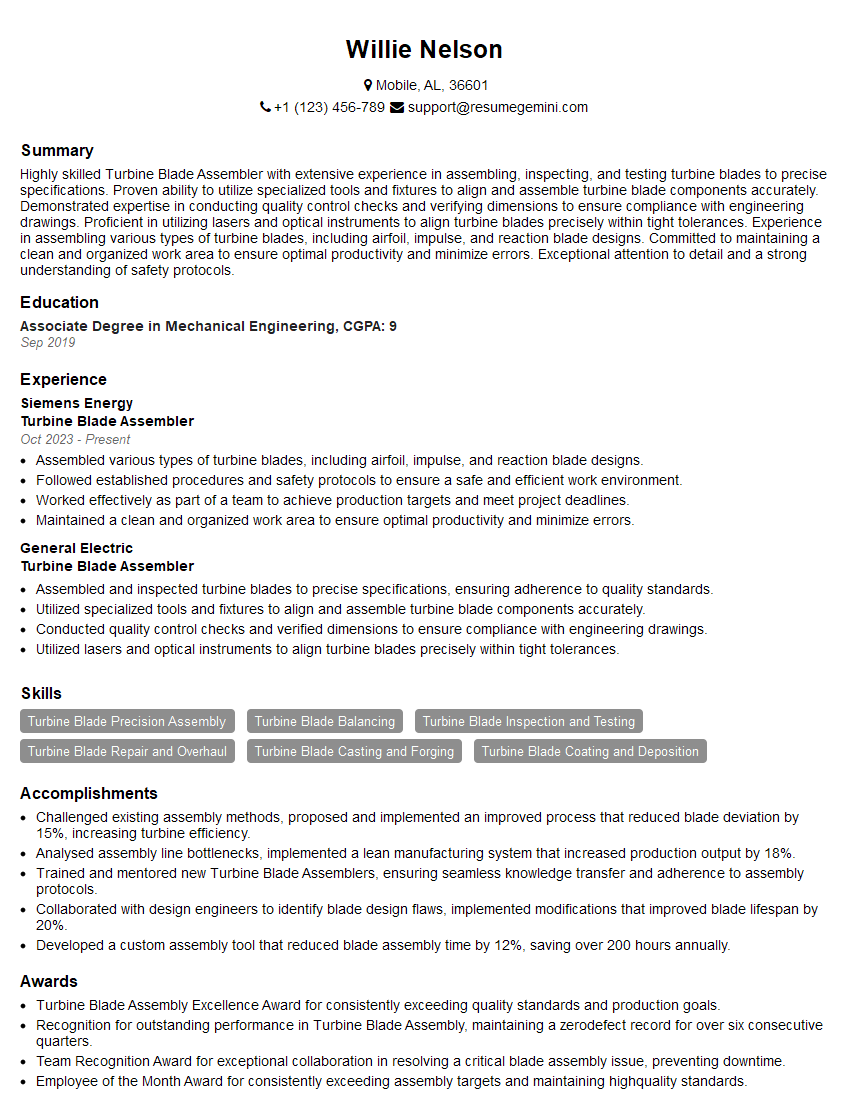

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turbine Blade Assembler

1. Describe the process of assembling turbine blades?

The process of assembling turbine blades involves the following steps:

- Inspecting the blades for any defects.

- Cleaning the blades to remove any contaminants.

- Applying a sealant to the blade roots.

- Inserting the blades into the turbine disc.

- Tightening the bolts that secure the blades to the disc.

- Balancing the turbine to ensure that it rotates smoothly.

2. What are the different types of turbine blades?

There are two main types of turbine blades:

Static blades

- These blades are fixed in place and do not move.

- They are used to direct the flow of air or gas through the turbine.

Moving blades

- These blades are attached to the turbine disc and rotate with it.

- They capture the energy of the moving air or gas and convert it into mechanical energy.

3. What are the materials used to make turbine blades?

Turbine blades are typically made from high-temperature alloys, such as:

- Nickel-based alloys

- Cobalt-based alloys

- Titanium alloys

These alloys are chosen for their high strength, corrosion resistance, and ability to withstand high temperatures.

4. What are the common defects found in turbine blades?

Some of the common defects found in turbine blades include:

- Cracks

- Voids

- Inclusions

- Erosion

- Corrosion

5. How do you inspect turbine blades for defects?

Turbine blades can be inspected for defects using a variety of methods, including:

- Visual inspection

- Ultrasonic testing

- Radiographic testing

- Eddy current testing

6. What is the importance of balancing a turbine?

Balancing a turbine is important to ensure that it rotates smoothly and without vibration.

- Vibration can damage the turbine and its components.

- It can also lead to noise and reduced efficiency.

7. What are the safety precautions that must be taken when working with turbine blades?

When working with turbine blades, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat.

- Be aware of the potential for sharp edges and rotating machinery.

- Do not attempt to work on a turbine that is running.

- Follow all manufacturer’s instructions and safety protocols.

8. What is your experience with working with turbine blades?

I have been working with turbine blades for the past 5 years.

- During that time, I have been responsible for assembling, inspecting, and repairing turbine blades.

- I am familiar with the different types of turbine blades and the materials used to make them.

- I am also familiar with the common defects found in turbine blades and the methods used to inspect them.

9. What are your strengths and weaknesses as a turbine blade assembler?

Strengths

- I am a highly skilled and experienced turbine blade assembler.

- I have a strong attention to detail and I am committed to quality workmanship.

- I am also a team player and I am always willing to help out my colleagues.

Weaknesses

- I sometimes have difficulty working under pressure.

- I am also not very good at multitasking.

10. Why do you want to work as a turbine blade assembler for our company?

I am interested in working as a turbine blade assembler for your company because I am confident that I have the skills and experience that you are looking for.

- I am also impressed by your company’s commitment to quality and safety.

- I believe that I would be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turbine Blade Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turbine Blade Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turbine Blade Assemblers play a vital role in the assembly and maintenance of turbine blades, ensuring the efficient operation and performance of gas turbines. Their responsibilities include:intro paragraph

1. Assembly and Installation

intro paragraph

- Assemble turbine blades according to engineering specifications.

- Install blades onto the turbine rotor or stator.

2. Inspection and Quality Control

intro paragraph

- Inspect blades for defects and ensure compliance with quality standards.

- Perform non-destructive testing (NDT) to assess blade integrity.

3. Maintenance and Repair

intro paragraph

- Repair and replace damaged blades.

- Perform preventive maintenance to minimize turbine downtime.

4. Troubleshooting and Analysis

intro paragraph

- Troubleshoot blade-related issues in gas turbines.

- Analyze blade performance data to identify areas for improvement.

Interview Tips

Preparing for an interview for a Turbine Blade Assembler position requires a combination of technical knowledge, industry experience, and presentation skills. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company’s history, products, and industry reputation. Understand the specific responsibilities of the Turbine Blade Assembler role and how it aligns with your skills and experience.

2. Highlight Your Technical Skills

Emphasize your knowledge of turbine blade assembly techniques, inspection methods, and non-destructive testing. Discuss your experience in using specialized tools and equipment, such as laser alignment systems and ultrasonic testing devices.

3. Showcase Your Attention to Detail

Turbine Blade Assemblers must be meticulous and quality-conscious. Highlight your ability to work with precision and accuracy, ensuring that blades meet all specifications and standards.

4. Demonstrate Problem-Solving Abilities

Share examples of how you have identified and resolved problems related to blade assembly or maintenance. Explain your troubleshooting process and the solutions you implemented.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Turbine Blade Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!