Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Turbine Engine Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

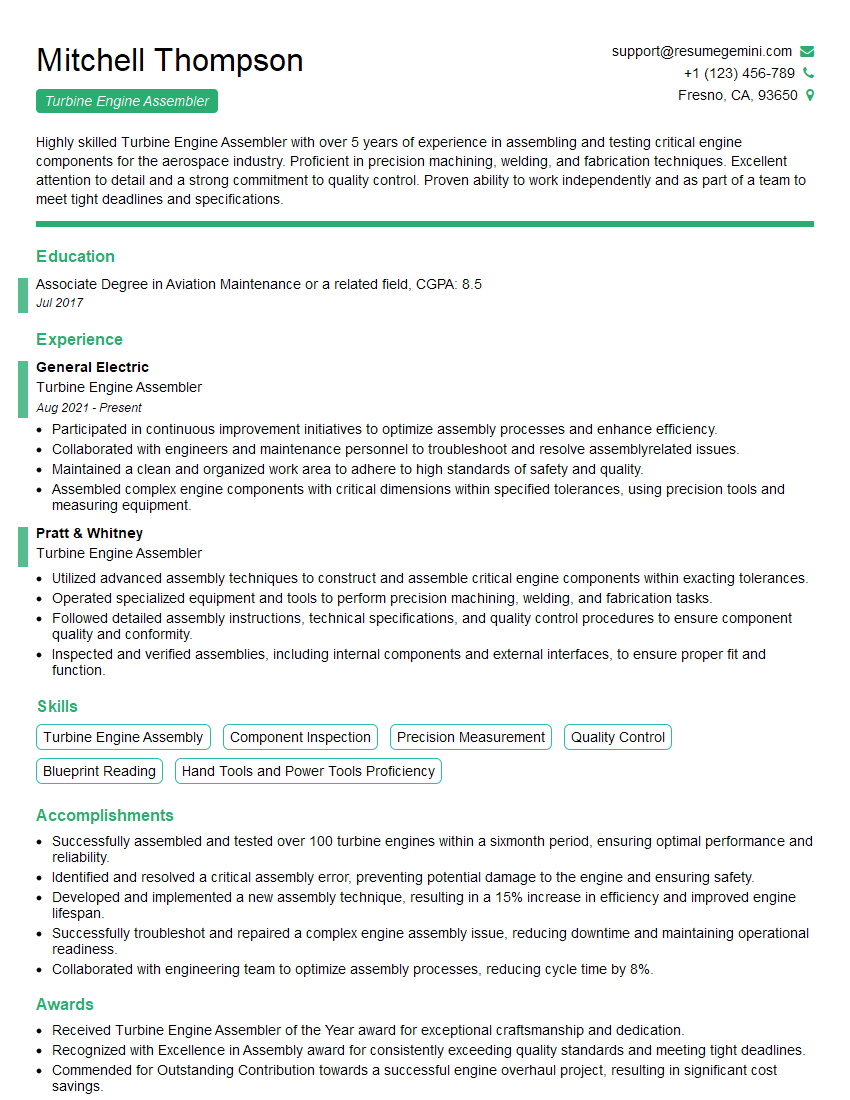

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turbine Engine Assembler

1. What are the responsibilities of a Turbine Engine Assembler?

- Assembles, disassembles, and repairs turbine engines and their components according to blueprints and specifications.

- Installs and replaces engine parts, such as blades, vanes, and bearings.

- Performs inspections and tests to ensure that engines meet performance and safety standards.

- Maintains and repairs engine accessories, such as fuel pumps, oil pumps, and electrical systems.

- Troubleshoots and resolves engine problems.

- Follows safety procedures and uses appropriate tools and equipment.

2. What are the different types of turbine engines?

subheading of the answer

- Axial-flow engines: These engines have a series of rotating blades (compressor blades) that compress air and a series of stationary blades (stator blades) that direct the airflow. Axial-flow engines are used in most jet engines.

- Centrifugal-flow engines: These engines have a single rotating impeller that compresses air. Centrifugal-flow engines are used in some small gas turbines and turbochargers.

subheading of the answer

- Radial-flow engines: These engines have a series of rotating blades that compress air radially outward. Radial-flow engines are used in some small gas turbines.

3. What are the materials used in the construction of turbine engines?

- High-temperature alloys: These alloys are used to make turbine blades and vanes, which are exposed to high temperatures and stresses.

- Titanium alloys: These alloys are used to make compressor blades and other components that need to be lightweight and strong.

- Stainless steels: These steels are used to make engine casings and other components that need to be corrosion-resistant.

- Composite materials: These materials are used to make engine fan blades and other components that need to be lightweight and durable.

4. What are the different methods of turbine engine assembly?

- Manual assembly: This method involves assembling the engine by hand, using a variety of tools and equipment.

- Automated assembly: This method involves using robotic equipment to assemble the engine.

- Combination assembly: This method involves a combination of manual and automated assembly.

5. What are the quality control procedures used in turbine engine assembly?

- Visual inspections: These inspections are used to check for defects in the engine components.

- Dimensional inspections: These inspections are used to check the dimensions of the engine components.

- Non-destructive testing: These tests are used to check for defects in the engine components without damaging them.

- Functional testing: These tests are used to check the performance of the engine.

6. What are the safety precautions that must be followed when working on turbine engines?

- Wear appropriate personal protective equipment (PPE). This includes safety glasses, gloves, and hearing protection.

- Be aware of the hazards associated with turbine engines. These hazards include rotating blades, high temperatures, and high pressures.

- Follow all safety procedures. These procedures are designed to protect you from injury.

- Never work on a turbine engine that is running.

7. What are the different tools and equipment used by Turbine Engine Assemblers?

- Wrenches: These tools are used to tighten and loosen bolts and nuts.

- Screwdrivers: These tools are used to tighten and loosen screws.

- Pliers: These tools are used to grip and hold objects.

- Hammers: These tools are used to drive nails and to shape metal.

- Measuring tools: These tools are used to measure the dimensions of engine components.

- Lifting equipment: This equipment is used to lift and move heavy engine components.

8. What are the challenges faced by Turbine Engine Assemblers?

- Working with hazardous materials. Turbine engines contain hazardous materials, such as fuels and lubricants, which can be harmful to health.

- Working in confined spaces. Turbine engines are often located in confined spaces, which can make it difficult to work on them.

- Working with heavy equipment. Turbine engines are heavy and can be difficult to move and lift.

- Working with precision. Turbine engines must be assembled with precision in order to function properly.

9. What is the career path for Turbine Engine Assemblers?

- Turbine Engine Assembler: This is the entry-level position for Turbine Engine Assemblers.

- Senior Turbine Engine Assembler: This position requires more experience and knowledge than the entry-level position.

- Lead Turbine Engine Assembler: This position is responsible for overseeing the work of other Turbine Engine Assemblers.

- Turbine Engine Inspector: This position is responsible for inspecting turbine engines to ensure that they meet safety and performance standards.

- Turbine Engine Repair Technician: This position is responsible for repairing turbine engines.

10. What are the skills and qualifications required to be a Turbine Engine Assembler?

- High school diploma or equivalent: This is the minimum education requirement for Turbine Engine Assemblers.

- Technical training in turbine engine assembly: This training can be obtained through a vocational school or community college.

- Experience working with turbine engines: This experience can be gained through an internship or apprenticeship.

- Strong mechanical skills: Turbine Engine Assemblers must have strong mechanical skills in order to assemble and repair turbine engines.

- Attention to detail: Turbine Engine Assemblers must have a strong attention to detail in order to ensure that engines are assembled correctly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turbine Engine Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turbine Engine Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turbine Engine Assemblers are responsible for assembling and testing turbine engines according to specifications. They use a variety of hand and power tools, as well as precision measuring equipment. They also troubleshoot and repair engines, and ensure that they meet performance standards. Key job responsibilities include:

1. Assembling turbine engines

This involves following blueprints and diagrams to assemble the various components of a turbine engine, including the compressor, combustor, turbine, and exhaust system.

- Following blueprints and diagrams

- Using a variety of hand and power tools

- Ensuring that all components are assembled correctly

2. Testing turbine engines

This involves running the engine to check its performance and make sure that it meets specifications. This may involve using a variety of test equipment, such as dynamometers, flow meters, and temperature sensors.

- Running the engine to check its performance

- Using a variety of test equipment

- Comparing the results to specifications

3. Troubleshooting and repairing turbine engines

This involves identifying and fixing problems with turbine engines. This may involve using a variety of diagnostic tools and techniques.

- Identifying and fixing problems with turbine engines

- Using a variety of diagnostic tools and techniques

- Ensuring that the engine meets performance standards

4. Maintaining turbine engines

This involves performing regular maintenance tasks on turbine engines, such as cleaning, lubricating, and inspecting. This helps to ensure that the engine operates at peak performance and lasts for a long time.

- Performing regular maintenance tasks

- Cleaning, lubricating, and inspecting the engine

- Ensuring that the engine operates at peak performance

Interview Tips

To prepare for an interview for a Turbine Engine Assembler position, it is important to research the company and the position itself. You should also practice answering common interview questions, such as:

1. Tell me about your experience with assembling turbine engines.

In your answer, be sure to highlight your relevant skills and experience, and how they make you a good fit for the position. For example, you might say something like:

- “I have over 10 years of experience assembling turbine engines for a major aerospace company. I have worked on a variety of engines, from small auxiliary power units to large jet engines. I am familiar with all aspects of engine assembly, including component identification, assembly, testing, and troubleshooting.”

2. What is your understanding of the different types of turbine engines?

In your answer, demonstrate your knowledge of the different types of turbine engines and their applications. For example, you might say something like:

- “There are two main types of turbine engines: axial flow and centrifugal flow. Axial flow engines are the most common type, and they are used in a wide range of applications, from aircraft to power plants. Centrifugal flow engines are less common, and they are typically used in smaller applications, such as drones and model airplanes.”

3. What are some of the challenges of assembling turbine engines?

In your answer, identify some of the challenges of assembling turbine engines, and how you have overcome them. For example, you might say something like:

- “One of the biggest challenges of assembling turbine engines is ensuring that all of the components are assembled correctly. This requires a high level of precision and attention to detail. I have overcome this challenge by developing a systematic approach to assembly, and by using a variety of quality control tools and techniques.”

4. What are your career goals?

In your answer, express your interest in the position and the company, and how it aligns with your career goals. For example, you might say something like:

- “I am excited about the opportunity to work as a Turbine Engine Assembler for your company. I am confident that my skills and experience would make me a valuable asset to your team. I am also eager to learn and grow within the company, and I believe that this position would be a great stepping stone for my career.”

Next Step:

Now that you’re armed with the knowledge of Turbine Engine Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Turbine Engine Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini