Are you gearing up for a career in Turner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Turner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

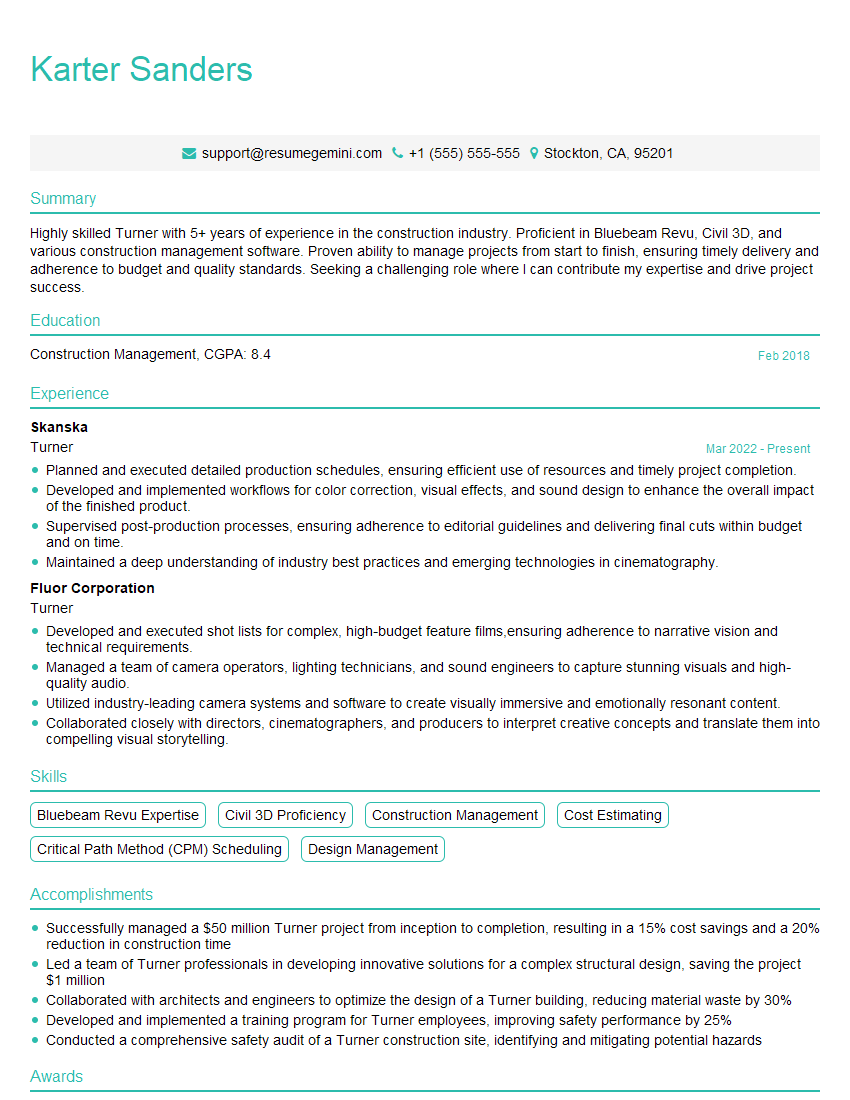

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turner

1. What is the difference between conventional lathe and CNC lathe?

A conventional lathe is a manually operated machine tool that requires the operator to control the cutting tool’s movement and speed. A CNC lathe, on the other hand, is a computer-controlled machine that can perform complex operations with a high degree of precision.

- CNC lathes are more accurate than conventional lathes.

- CNC lathes can perform more complex operations than conventional lathes.

- CNC lathes are more efficient than conventional lathes.

2. What are the different types of CNC lathes?

Horizontal CNC lathe

- Used for turning cylindrical parts.

- The workpiece is held in a chuck or collet and rotated while the cutting tool moves along the axis of rotation.

Vertical CNC lathe

- Used for turning large or heavy parts.

- The workpiece is mounted on a vertical table and rotated while the cutting tool moves along the vertical axis.

Turret CNC lathe

- Used for turning complex parts.

- The cutting tools are mounted on a turret that is rotated to bring the desired tool into position.

3. What is the importance of CNC lathe safety?

CNC lathes are powerful machines that can cause serious injury if they are not operated properly. It is important to follow all safety procedures when operating a CNC lathe, including:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keeping the work area clean and free of debris.

- Never operating a CNC lathe while under the influence of alcohol or drugs.

- Following all lockout/tagout procedures before performing maintenance on a CNC lathe.

4. What are the different types of CNC lathe tools?

There are many different types of CNC lathe tools, each with its own specific purpose. Some of the most common types of CNC lathe tools include:

- Turning tools

- Facing tools

- Boring tools

- Grooving tools

- Threading tools

5. How do you program a CNC lathe?

CNC lathes are programmed using a computer program called G-code. G-code is a language that tells the CNC lathe how to move its cutting tool. To program a CNC lathe, you need to first create a CAD drawing of the part you want to make. Once you have created a CAD drawing, you need to convert it into G-code. There are many different software programs that can be used to convert CAD drawings into G-code.

6. What are the different types of CNC lathe operations?

CNC lathes can perform a variety of different operations, including:

- Turning

- Facing

- Boring

- Grooving

- Threading

7. What is the difference between absolute and incremental programming?

Absolute programming tells the CNC lathe to move to a specific point in space. Incremental programming tells the CNC lathe to move a certain distance from its current position.

8. What are the different types of CNC lathe coordinate systems?

There are two different types of CNC lathe coordinate systems: absolute and incremental. Absolute coordinate systems are based on a fixed point in space, while incremental coordinate systems are based on the current position of the cutting tool.

9. How do you set up a CNC lathe?

To set up a CNC lathe, you need to first mount the workpiece on the lathe. Once the workpiece is mounted, you need to set the zero point of the coordinate system. You also need to set the speed and feed of the cutting tool.

10. How do you maintain a CNC lathe?

To maintain a CNC lathe, you need to regularly clean and lubricate the machine. You also need to check the cutting tools for wear and tear. If a cutting tool is worn or damaged, it needs to be replaced.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Turner’s primary job responsibility is to operate lathes, boring mills, and other machine tools to shape and finish metal parts.

1. Preparing and setting up machines

Turner prepares and sets up the machines they will operate, considering the workpiece’s material, dimensions, and required tolerance levels.

- Selecting and installing the appropriate cutting tools and accessories.

- Setting up workpiece and adjusting machine parameters.

2. Operating machines

Turner operates machines to cut, shape, and finish metal parts, following the specified blueprints or instructions.

- Monitoring the machining process and making necessary adjustments.

- Ensuring that the finished parts meet the required specifications.

3. Inspecting and measuring parts

Turner inspects and measures finished parts to ensure they meet the required specifications.

- Using measuring tools and gauges to check dimensions and tolerances.

- Identifying and correcting any defects or errors.

4. Maintaining machines

Turner maintains machines to ensure they are in good working condition.

- Performing routine maintenance and cleaning tasks.

- Identifying and troubleshooting any mechanical issues.

Interview Tips

To enhance your chances of success in a Turner interview, it is important to prepare thoroughly. Here are some tips and tricks to help you:

1. Research the Company and Position

Take the time to learn about the company and the specific Turner role you are applying for. Study the company’s website and social media pages to gain insights into their culture, values, and areas of expertise.

- Familiarize yourself with the company’s products or services to demonstrate your interest and alignment with their business.

- Understand the key responsibilities and qualifications required for the role to tailor your answers accordingly.

2. Practice Your Answers

Anticipate common interview questions related to your skills, experience, and motivations. Prepare concise and well-structured answers that highlight your strengths and relevance to the position.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments and problem-solving abilities.

- Practice delivering your answers aloud to improve your confidence and fluency.

3. Showcase Your Technical Expertise

As a Turner, your technical skills are paramount. Emphasize your proficiency in operating various machines, interpreting blueprints, and inspecting parts.

- Highlight your experience with specific types of machines and materials relevant to the role.

- Provide examples of projects where you applied your technical knowledge to achieve successful outcomes.

4. Highlight Your Attention to Detail

Precision and attention to detail are essential qualities for Turners. Quantify your achievements in ensuring accuracy and meeting tight tolerances.

- Share metrics or success stories that demonstrate your ability to produce high-quality parts consistently.

- Explain your approach to error detection and correction to convey your commitment to delivering defect-free work.

5. Display Your Problem-Solving Abilities

Turners often encounter unexpected challenges. Highlight your ability to identify and resolve technical issues effectively.

- Describe a situation where you diagnosed and fixed a machine malfunction.

- Share an example of how you optimized a process or improved efficiency while maintaining quality standards.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Turner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.