Are you gearing up for an interview for a Turning Lathe Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Turning Lathe Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

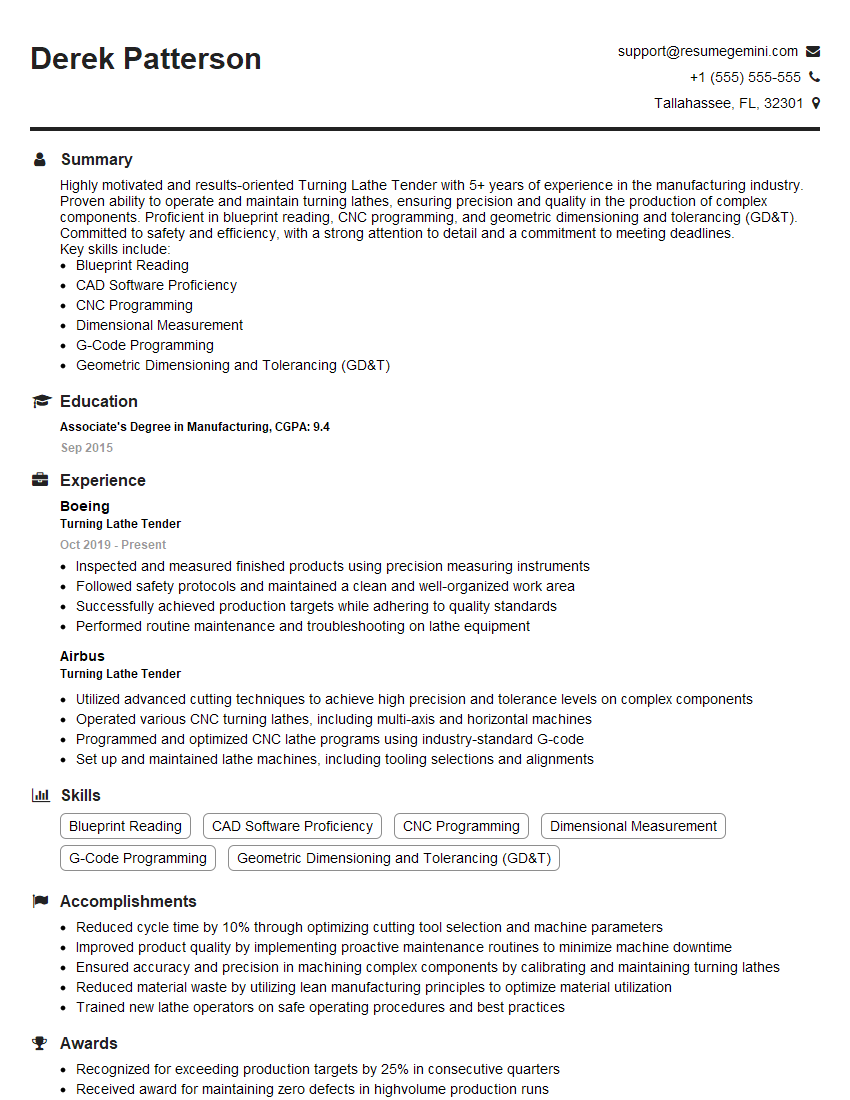

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turning Lathe Tender

1. What are the different types of turning lathes?

There are various types of turning lathes, including:

- Engine lathes: These are general-purpose lathes used for a wide range of turning operations.

- Turret lathes: These have a turret with multiple tool holders, allowing for quick tool changes and efficient production.

- CNC lathes: These are computer-controlled lathes that offer high precision and automation.

2. How do you set up a turning lathe?

Centering the work:

- Use a live center or dead center to support the workpiece.

- Align the workpiece with the lathe’s spindle.

Mounting the cutting tool:

- Select the appropriate cutting tool for the material and operation.

- Mount the tool in the toolpost and adjust its height and angle.

3. What are the common turning operations?

Common turning operations include:

- Straight turning: Removing material to create a cylindrical surface.

- Taper turning: Removing material to create a conical surface.

- Facing: Machining the surface of the workpiece perpendicular to its axis.

- Grooving: Cutting a recess or groove into the workpiece.

- Threading: Cutting threads on the workpiece.

4. How do you determine the correct cutting speed and feed rate for turning?

The correct cutting speed and feed rate depend on:

- Material of the workpiece: Different materials have different cutting speeds.

- Size and shape of the workpiece: Larger workpieces require lower feed rates.

- Type of cutting tool: Different tools have different cutting speeds and feed rates.

- Lathe specifications: The maximum speed and feed rate of the lathe must be considered.

5. What are the safety precautions to observe when operating a turning lathe?

Safety precautions include:

- Wearing proper safety gear, including eye protection, gloves, and hearing protection.

- Ensuring the lathe is properly grounded and all guards are in place.

- Never reaching over a rotating workpiece or cutting tool.

- Using sharp cutting tools to minimize chatter and vibration.

- Regularly cleaning the lathe and work area to prevent accidents.

6. What are the common problems that occur in turning operations?

Common problems include:

- Chatter: Vibration during cutting, caused by an unstable setup or dull cutting tools.

- Taper turning: The workpiece is not turning parallel to the spindle axis.

- Tool breakage: Excessive force, improper tool selection, or a dull tool can cause breakage.

- Workpiece deformation: The workpiece may deform under the cutting forces.

- Poor surface finish: Caused by incorrect cutting parameters, dull tools, or improper workpiece preparation.

7. How do you troubleshoot and resolve problems with turning operations?

Troubleshooting involves:

- Identifying the problem: Observe the workpiece, cutting tool, and lathe settings.

- Checking the setup: Ensure the workpiece is securely held and the cutting tool is properly mounted.

- Adjusting cutting parameters: Modify the cutting speed, feed rate, or depth of cut.

- Inspecting the cutting tool: Check for wear, damage, or improper grinding.

- Consulting reference materials: Seek guidance from manuals, books, or online resources.

8. How do you measure and inspect turned parts?

Inspection involves:

- Using precision measuring tools, such as calipers, micrometers, and height gauges.

- Checking dimensions according to the part drawing.

- Examining the surface finish for smoothness and accuracy.

- Verifying the thread pitch and tolerances using thread gauges.

- Conducting non-destructive testing, such as magnetic particle inspection, to detect flaws.

9. How do you maintain a turning lathe?

Maintenance includes:

- Regular cleaning and lubrication of all moving parts.

- Replacing worn or damaged components, such as belts, bearings, and gears.

- Checking and adjusting the lathe’s alignment to ensure precision.

- Monitoring coolant levels and maintaining proper filtration.

- Performing electrical safety checks to prevent hazards.

10. What is your experience with programming and operating CNC turning lathes?

If applicable, highlight:

- Proficiency in CNC programming languages, such as G-code and M-code.

- Experience using CAM software to generate toolpaths.

- Knowledge of CNC machine setup and operation.

- Ability to troubleshoot and resolve CNC-related issues.

- Examples of successful CNC turning projects undertaken.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turning Lathe Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turning Lathe Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Turning Lathe Tender is responsible for operating, maintaining, and repairing turning lathes, which are machines used to shape and cut metal objects. Some additional key job responsibilities include:

1. Preparing Lathes

Setting up and configuring the turning lathe according to specific job requirements, including selecting and installing the appropriate tooling, workpieces, and cutting fluids.

2. Operating Lathes

Safely and efficiently operating the lathe to perform specific tasks, such as turning, facing, boring, and threading.

3. Monitoring Lathes

Continuously monitoring the lathe during operation to ensure it is functioning correctly and making adjustments as needed to maintain optimal performance.

4. Maintaining Lathes

Performing preventative maintenance tasks, such as lubricating and cleaning the lathe, to ensure it is in good working condition.

5. Troubleshooting Lathes

Identifying and resolving any issues that may arise with the lathe, including mechanical, electrical, or software problems.

6. Quality Control

Inspecting finished workpieces to ensure they meet the required specifications and quality standards.

7. Record-Keeping

Maintaining accurate records of lathe operations, including production data, maintenance activities, and any issues encountered.

Interview Tips

Preparing thoroughly for an interview for a Turning Lathe Tender position can significantly increase your chances of success. Here are some helpful tips to help you prepare:

1. Research the Company and Position:

Take the time to learn about the company you are applying to, including its industry, size, and culture. Additionally, thoroughly review the job description to understand the specific requirements and responsibilities of the Turning Lathe Tender role.

2. Practice Common Interview Questions:

Prepare for common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses?” You can find many resources online or in books that provide sample questions and answers. Practicing your responses will help you feel more confident and articulate during the actual interview.

3. Highlight Relevant Skills and Experience:

Carefully review the job description and identify the skills and experience that are most relevant to the Turning Lathe Tender role. In your resume and cover letter, be sure to highlight these skills and provide specific examples of how you have applied them in your previous work experience. Quantifying your accomplishments with specific metrics will make your application more impressive.

4. Prepare Questions for the Interviewer:

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions about the company, the role, or the industry. This is also an opportunity to clarify any details or to demonstrate your enthusiasm for the position.

5. Dress Appropriately:

First impressions matter, so make sure to dress appropriately for the interview. A clean and pressed business casual attire is generally recommended. Avoid wearing clothing that is too revealing, wrinkled, or casual.

6. Arrive on Time and Be Enthusiastic:

Punctuality and a positive attitude are essential for a successful interview. Plan your route in advance to ensure you arrive on time, and greet the interviewer with a firm handshake and a smile. Throughout the interview, maintain a positive and enthusiastic demeanor to convey your interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Turning Lathe Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.