Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Turning Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

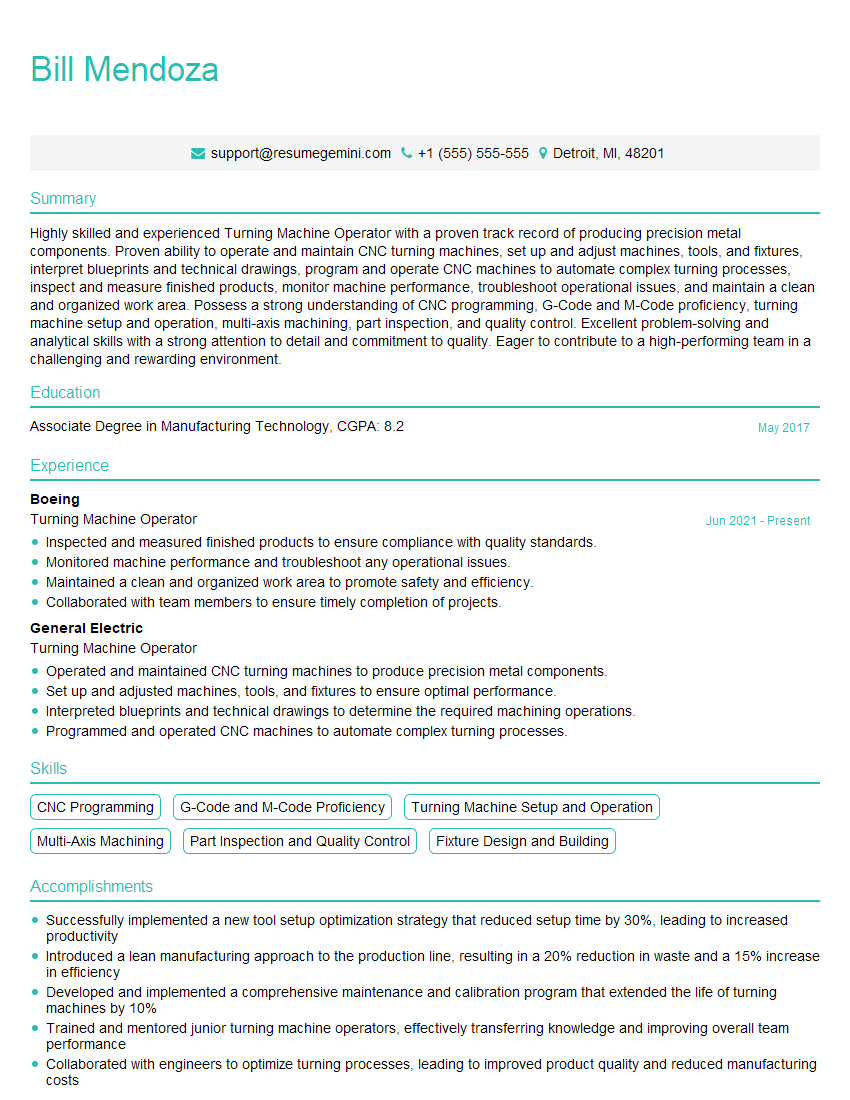

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turning Machine Operator

1. Describe the process of setting up a turning machine for a new job.

The process of setting up a turning machine for a new job involves several steps to ensure accurate and efficient operation:

- Review the job specifications: Carefully review the engineering drawings, work orders, and any other relevant documentation to understand the required dimensions, tolerances, and surface finish.

- Select and mount the workpiece: Choose the appropriate workpiece material and securely mount it on the machine’s chuck or faceplate using the correct fixtures and tooling.

- Install and adjust tooling: Select and install the necessary cutting tools, such as turning tools, boring bars, and inserts, based on the required operations.

- Set machine parameters: Determine and set the appropriate machine parameters, including spindle speed, feed rate, and depth of cut, according to the material and cutting tool specifications.

- Program the machine (if applicable): For CNC turning machines, create or load the CNC program that specifies the toolpath, cutting parameters, and other instructions for automated operation.

- Perform a dry run (if possible): Before running the machine with the workpiece, conduct a dry run to verify the toolpath and ensure that there are no collisions or errors.

2. What types of cutting tools are commonly used in turning operations?

Turning tools

- Carbide inserts

- High-speed steel (HSS) tools

- Ceramic tools

Boring bars

- Solid carbide boring bars

- Indexable boring bars

- Adjustable boring heads

Other tools

- Knurling tools

- Parting tools

- Grooving tools

- Threading tools

3. How do you calculate the spindle speed and feed rate for a turning operation?

Spindle speed and feed rate are crucial parameters in turning operations, and they are calculated based on the material properties, cutting tool characteristics, and desired surface finish:

- Spindle speed (rpm): Determined by the cutting tool material, workpiece material, and desired surface finish. Empirical formulas or manufacturer recommendations can be used.

- Feed rate (mm/rev or in/rev): Determined by the cutting tool geometry, workpiece material, and desired surface finish. Higher feed rates result in faster material removal but may affect surface quality.

4. What are the different types of turning operations?

Turning operations involve various techniques to shape and finish workpieces on a lathe:

- Straight turning: Reducing the diameter of a cylindrical workpiece evenly along its length.

- Taper turning: Creating a conical shape by gradually reducing the diameter.

- Facing: Machining the end surface of a workpiece perpendicular to the axis of rotation.

- Boring: Enlarging or creating a cylindrical hole in a workpiece.

- Knurling: Creating a textured surface on a workpiece for better grip or aesthetics.

- Threading: Cutting threads on the workpiece for assembly or fastening purposes.

- Grooving: Creating grooves or slots on the workpiece for various functional or aesthetic reasons.

5. How do you troubleshoot common problems encountered in turning operations?

Troubleshooting common problems in turning operations requires a systematic approach:

- Identify the problem: Determine the specific issue, such as tool breakage, poor surface finish, or excessive vibration.

- Check machine settings: Verify that the machine parameters, including spindle speed, feed rate, and cutting tool settings, are correct.

- Inspect cutting tools: Examine the cutting tools for signs of wear, damage, or improper mounting.

- Check workpiece: Ensure that the workpiece is properly secured and aligned.

- Adjust parameters: Modify machine settings or cutting tool selection as necessary to resolve the issue.

6. What is the importance of coolant in turning operations?

- Lubrication: Coolant reduces friction between the cutting tool and workpiece, improving tool life and surface finish.

- Cooling: Coolant removes heat generated during cutting, preventing thermal damage to the workpiece and cutting tool.

- Chip removal: Coolant helps to flush away chips and debris from the cutting zone, ensuring proper cutting conditions.

- Corrosion protection: Coolant can contain additives that prevent corrosion on the workpiece and machine components.

7. How do you measure and ensure the accuracy of turned parts?

- Measuring tools: Use precision measuring tools such as micrometers, calipers, and dial indicators to measure dimensions and tolerances.

- Inspection procedures: Follow established inspection procedures to verify conformance to specifications.

- Calibration: Regularly calibrate measuring tools to ensure accuracy.

- Statistical process control (SPC): Implement SPC techniques to monitor and control the turning process, identifying and correcting deviations from desired specifications.

8. What safety precautions should be taken when operating a turning machine?

- Wear appropriate PPE: Safety glasses, gloves, and earplugs should be worn at all times.

- Secure loose clothing: Loose clothing or jewelry can get caught in moving parts.

- Keep the work area clean: Clear away chips and debris to prevent slips or falls.

- Be aware of moving parts: Pay attention to the rotating spindle, chuck, and other moving components.

- Follow lockout/tagout procedures: Lock out and tag out the machine before performing maintenance or repairs.

9. What is your experience with different types of turning machines?

Describe your experience with various types of turning machines, such as manual lathes, CNC lathes, and multitasking machines:

- Manual lathes: Highlight your proficiency operating manual lathes, including setting up, tool selection, and performing basic turning operations.

- CNC lathes: Describe your skills in programming and operating CNC lathes, including creating and modifying CNC programs, setting up tooling, and monitoring the machining process.

- Multitasking machines: Explain your experience with multitasking machines that combine turning, milling, and other operations in a single setup, increasing efficiency and reducing cycle times.

10. How do you stay up-to-date with advancements in turning technology?

- Attend industry events: Participate in trade shows, conferences, and workshops to learn about the latest technologies and best practices.

- Read industry publications: Subscribe to technical journals and magazines to stay informed about new developments in the field.

- Online learning: Take online courses or webinars offered by reputable institutions or industry experts.

- Networking: Connect with other professionals in the industry to share knowledge and learn from their experiences.

- Manufacturer training: Attend training programs offered by turning machine manufacturers to gain in-depth knowledge about their latest products and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turning Machine Operators are responsible for operating turning machines to create precision metal parts. They use their knowledge of machining techniques and equipment to produce high-quality products.

1. Machine Operation

Operate turning machines to cut, shape, and finish metal parts according to specifications

- Set up and adjust machines

- Monitor machines during operation

2. Quality Control

Inspect finished parts for accuracy and quality

- Use measuring instruments to check dimensions

- Identify and correct defects

3. Maintenance and Repair

Perform basic maintenance and repair on turning machines

- Lubricate and clean machines

- Replace worn or damaged parts

4. Safety

Follow safety procedures and wear appropriate personal protective equipment (PPE)

- Use machine guards and safety glasses

- Operate machines in a safe manner

Interview Tips

Interviews for Turning Machine Operator positions can be challenging, but with the right preparation, you can ace it.

1. Research the Company and Position

Before the interview, take some time to research the company and the position. This will help you understand their needs and how your skills and experience can benefit them.

- Visit the company website

- Look up industry news and trends

2. Practice Your Answers

Prepare for common interview questions and practice your answers. This will help you feel more confident and articulate during the interview.

- Brainstorm potential questions

- Rehearse your answers out loud

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. Quantify your accomplishments and provide specific examples.

- Use action verbs to describe your work experience

- Provide examples of your problem-solving and decision-making abilities

4. Be Enthusiastic and Professional

First impressions matter, so be sure to dress professionally and arrive on time for your interview. Show enthusiasm for the position and be respectful of the interviewer’s time.

- Make eye contact and smile

- Be polite and respectful

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Turning Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Turning Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.