Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Turret Lathe Machinist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Turret Lathe Machinist so you can tailor your answers to impress potential employers.

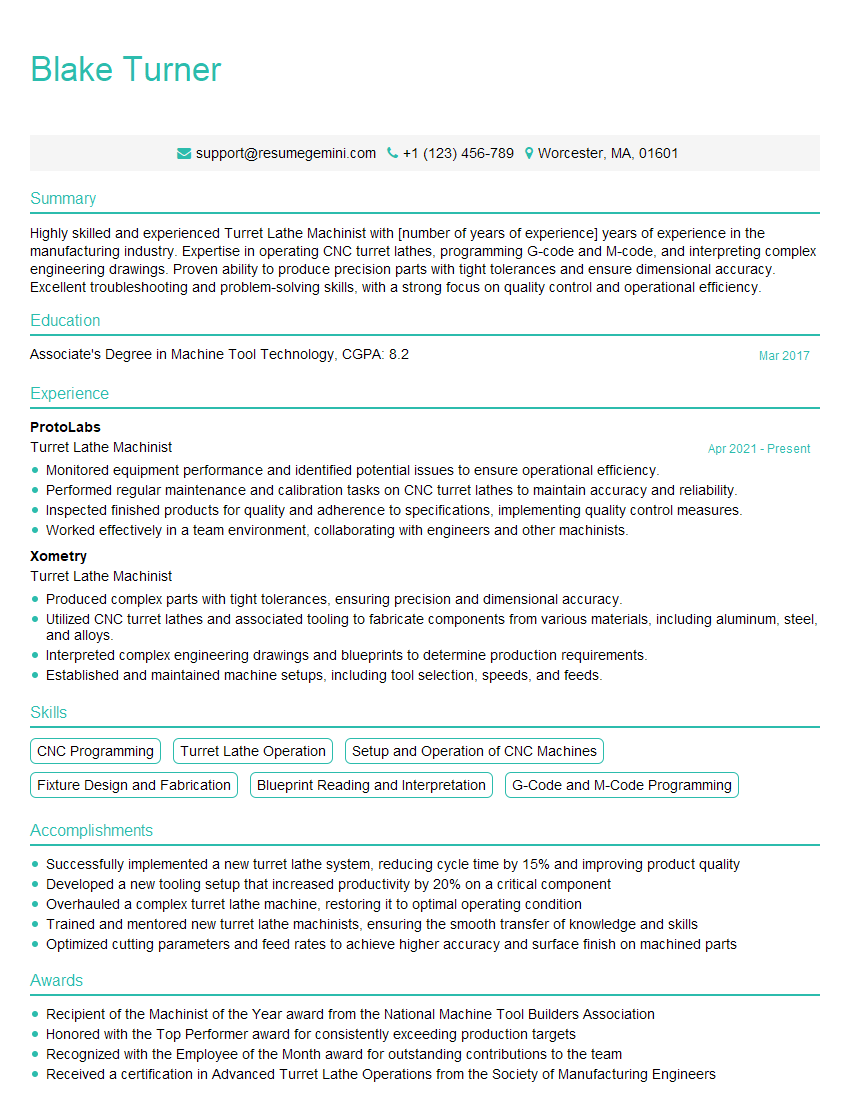

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turret Lathe Machinist

1. Describe the step-by-step process involved in setting up a turret lathe for a new job.

- Confirm the job specifications and gather necessary tooling and materials.

- Mount the workpiece securely in the chuck or collet.

- Select and install the appropriate tool holders in the turret.

- Set tool offsets and zero the axes for accurate positioning.

- Program the desired machining operations using the machine’s CNC system.

- Run a test cycle to verify program functionality.

- Adjust tool settings and offsets as needed to achieve desired dimensions and surface finish.

2. Explain the different types of turret lathe operations and how to select the correct one for a given task.

Turning

- Facing: Creating a flat surface perpendicular to the axis of rotation.

- Straight turning: Removing material to create a cylindrical shape.

Boring

- Enlarging an existing hole or creating a new one.

Drilling

- Creating a cylindrical hole using a drill bit.

Thread cutting

- Creating internal or external threads using a cutting tool.

3. Describe the safety precautions that must be taken when operating a turret lathe.

- Wear appropriate safety gear, including safety glasses, gloves, and ear protection.

- Ensure the machine is properly grounded and maintained.

- Keep work area clear of debris and tripping hazards.

- Never attempt to remove or adjust tooling while the machine is running.

- Follow all manufacturer’s instructions and safety protocols.

4. What is tool offset and how is it used to ensure accuracy during machining?

Tool offset is a setting that compensates for the difference between the actual tool position and its theoretical position in the CNC program. It allows precise positioning of the tool relative to the workpiece by adjusting the machine’s coordinates. By measuring the actual tool length and entering it into the offset value, the machine can automatically adjust its movements to maintain accuracy.

5. Describe the different types of cutting tools used in turret lathe operations and how to select the appropriate one for a given material and application.

- High-speed steel (HSS): General-purpose tools suitable for a wide range of materials.

- Carbide: Harder and more wear-resistant, ideal for high-production applications.

- Ceramic: Extremely hard and wear-resistant, used for high-temperature machining.

- Diamond: The hardest cutting tool, used for machining hard and abrasive materials.

6. What is the difference between a turret lathe and a CNC lathe?

- Turret lathe is manually operated, requiring the machinist to manually control the tool movement.

- CNC lathe is computer-controlled, allowing for automated machining based on a pre-programmed code.

- CNC lathe offers increased precision, repeatability, and productivity.

7. Explain the importance of lubrication in turret lathe operations.

- Reduces friction and heat generation, prolonging tool life.

- Improves surface finish by reducing tool chatter and vibration.

- Prevents metal-to-metal contact, protecting the machine components.

- Flushes away metal chips and debris from the cutting zone.

8. Describe the different types of coolant systems used in turret lathe operations.

- Flood cooling: A large volume of coolant is sprayed over the cutting zone.

- Mist cooling: A fine mist of coolant is directed at the cutting zone.

- Jet cooling: A high-pressure jet of coolant is focused on the cutting tool.

9. What is the purpose of a tailstock in a turret lathe?

The tailstock is a movable support that provides additional stability for the workpiece, especially during drilling or boring operations. It consists of a spindle that can be extended or retracted to accommodate different workpiece lengths and a center that supports the opposite end of the workpiece from the chuck.

10. Describe the common maintenance tasks required for a turret lathe.

- Cleaning and lubricating all moving parts regularly.

- Checking and replacing worn or damaged parts, such as belts, pulleys, and bearings.

- Inspecting and calibrating the machine’s measuring instruments for accuracy.

- Following manufacturer’s recommendations for preventive maintenance schedules.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turret Lathe Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turret Lathe Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Turret Lathe Machinist:

A Turret Lathe Machinist is responsible for operating and maintaining turret lathes to produce precision metal parts. Key job responsibilities include:

1. Machine Part Operation

Setting up and operating turret lathes to produce complex parts according to specifications.

- Interpreting technical drawings and blueprints.

- Selecting and mounting tools and workpieces.

2. Part Quality Control

Inspecting and measuring parts to ensure they meet required dimensions and tolerances.

- Using precision measuring instruments and gauges.

- Identifying and correcting any deviations from specifications.

3. Machine Maintenance

Performing preventive maintenance on turret lathes to ensure optimal performance and longevity.

- Lubricating and cleaning machines.

- Replacing worn or damaged parts.

4. Tool Management

Selecting, sharpening, and maintaining cutting tools for efficient machining.

- Monitoring tool wear and making adjustments as needed.

- Ensuring optimal cutting speeds and feeds.

Interview Preparation Tips for Turret Lathe Machinists:

To ace an interview for a Turret Lathe Machinist position, candidates should:

1. Research the Company and Position

Learn about the company’s products, services, and culture. Study the job description thoroughly to understand the specific responsibilities and qualifications required.

2. Highlight Relevant Experience

Emphasize your previous experience operating turret lathes and producing precision parts. Provide specific examples of your accomplishments and the results you achieved.

3. Showcase Technical Skills

Demonstrate your proficiency in blueprint reading, tool selection, and machining techniques. Explain how you ensure part accuracy and quality control.

4. Discuss Maintenance Expertise

Explain your understanding of turret lathe maintenance procedures. Describe your experience in troubleshooting and resolving mechanical issues to minimize downtime.

5. Practice Interview Questions

Anticipate common interview questions and prepare your answers. Practice speaking clearly and confidently, and be ready to provide detailed examples of your skills and experience.

6. Ask Insightful Questions

Show your enthusiasm and engagement by asking thoughtful questions about the job, the company, and the industry. This demonstrates your interest and eagerness to learn.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Turret Lathe Machinist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.