Are you gearing up for an interview for a Turret Lathe Set Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Turret Lathe Set Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

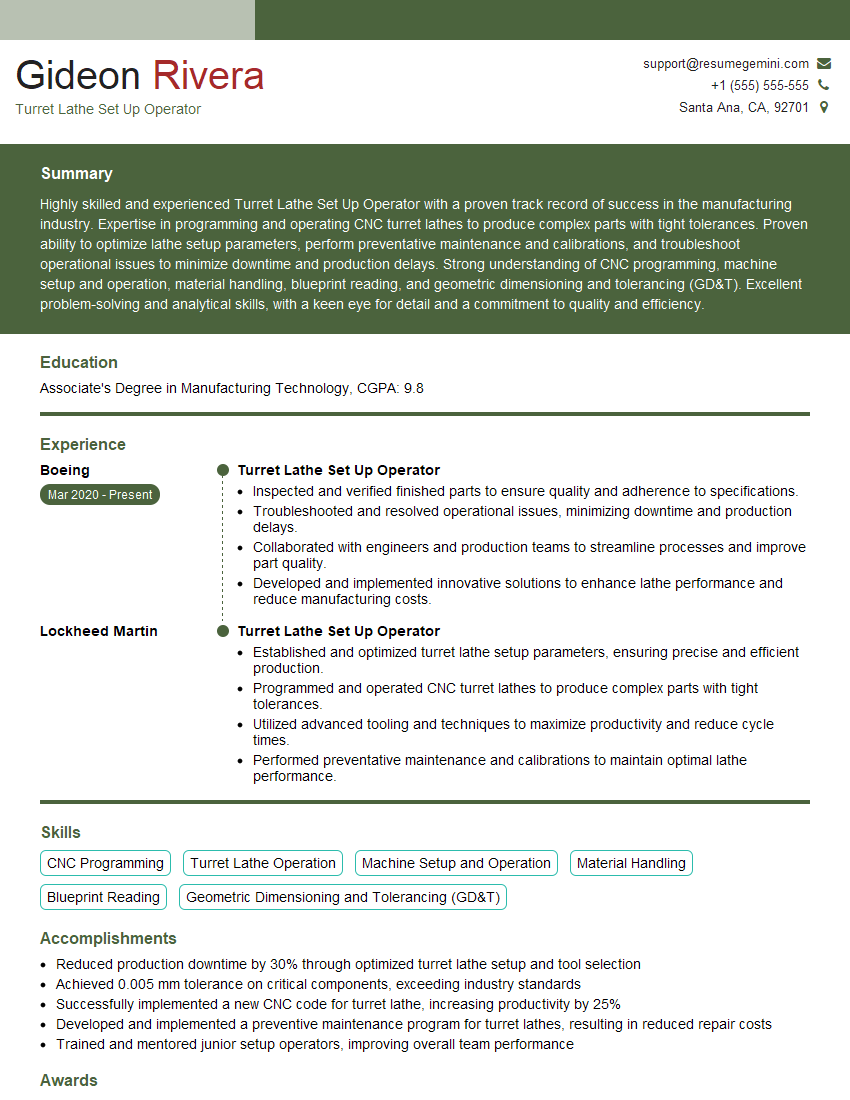

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turret Lathe Set Up Operator

1. How do you measure the accuracy of a turret lathe?

To measure the accuracy of a turret lathe, I use a variety of precision measuring tools such as:

- Dial indicators

- Micrometers

- Calipers

- Gauges

I also perform regular test cuts to ensure that the machine is producing parts within the specified tolerances.

2. What are the different types of tooling that can be used on a turret lathe?

Cutting Tools

- Turning tools

- Boring bars

- Facing tools

- Grooving tools

- Threading tools

Holding Tools

- Chucks

- Collets

- Arbors

- Centers

3. How do you set up a turret lathe to perform a specific operation?

To set up a turret lathe for a specific operation, I follow these steps:

- Select the appropriate tooling for the operation.

- Mount the tooling in the turret and adjust its position.

- Set the spindle speed and feed rate.

- Load the workpiece into the chuck or collet.

- Program the machine to perform the desired operations.

- Run the program and monitor the process.

4. What are the safety precautions that must be followed when operating a turret lathe?

When operating a turret lathe, I always follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine with loose clothing or jewelry that could get caught in moving parts.

- Secure the workpiece properly before starting the machine.

- Be aware of the location of the emergency stop button and know how to use it.

5. How do you troubleshoot common problems that may occur while operating a turret lathe?

Some common problems that may occur while operating a turret lathe include:

- Tool chatter: This can be caused by a number of factors, such as incorrect tool geometry, excessive feed rate, or insufficient rigidity in the workpiece or machine.

- Poor surface finish: This can be caused by a number of factors, such as dull or damaged tooling, excessive feed rate, or incorrect cutting fluid.

- Dimensional errors: This can be caused by a number of factors, such as incorrect setup, worn or damaged tooling, or backlash in the machine.

To troubleshoot these problems, I typically start by checking the following:

- Tooling: Is the tooling sharp and in good condition? Is it correctly mounted and adjusted?

- Setup: Is the workpiece properly secured? Are the spindle speed and feed rate correct?

- Machine: Is the machine in good condition? Are there any loose or worn components?

6. What is your experience with programming CNC turret lathes?

I have experience programming CNC turret lathes using a variety of software packages, including:

- Siemens ShopMill

- Heidenhain iTNC

- Fanuc Oi

I am proficient in using these software packages to create and edit programs, set up tool offsets, and simulate machining operations.

7. How do you maintain a turret lathe to keep it in good working condition?

To maintain a turret lathe in good working condition, I perform the following tasks:

- Regularly clean and lubricate the machine.

- Check and adjust the tool offsets.

- Inspect the tooling for wear or damage.

- Calibrate the machine according to the manufacturer’s recommendations.

- Keep a log of maintenance activities.

8. What are some of the challenges you have faced while working as a turret lathe set up operator?

Some of the challenges I have faced while working as a turret lathe set up operator include:

- Meeting tight tolerances: Turret lathes are capable of producing very precise parts, but it can be challenging to meet tight tolerances consistently.

- Working with complex geometries: Some parts have complex geometries that can be difficult to machine.

- Troubleshooting problems: When problems occur, it can be time-consuming to identify and fix them.

9. How do you stay up-to-date on the latest developments in turret lathe technology?

I stay up-to-date on the latest developments in turret lathe technology by:

- Attending industry trade shows and conferences.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Talking to other turret lathe operators and engineers.

10. What are your goals for your career as a turret lathe set up operator?

My goals for my career as a turret lathe set up operator are to:

- Become a highly skilled and experienced operator.

- Work on challenging and rewarding projects.

- Contribute to the success of my company.

- Earn a reputation for excellence in my field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turret Lathe Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turret Lathe Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Turret Lathe Set Up Operator is responsible for setting up and operating turret lathes to produce complex metal parts. They ensure that the machine is running smoothly and efficiently, and that the parts being produced meet the required specifications. Some of the key responsibilities of a Turret Lathe Set Up Operator include:

1. Machine Setup

Setting up the turret lathe according to the job requirements, including loading the raw material, mounting the cutting tools, and programming the machine.

- Reading and understanding blueprints and work orders to determine the required dimensions and tolerances for the parts being produced.

- Selecting the appropriate tooling and workpiece materials for the job.

- Installing and aligning the cutting tools in the turret.

- Programming the lathe to perform the required operations, including setting speeds, feeds, and tool paths.

2. Machine Operation

Operating the turret lathe to produce the parts according to the programmed instructions, monitoring the machine’s operation, and making adjustments as needed.

- Starting and stopping the machine.

- Monitoring the machine’s operation and making adjustments to ensure that the parts being produced meet the required specifications.

- Changing tools and workpieces as needed.

- Inspecting the finished parts to ensure that they meet the required quality standards.

3. Maintenance and Troubleshooting

Performing basic maintenance and troubleshooting on the turret lathe, identifying and resolving common problems, and reporting any major issues to a supervisor.

- Cleaning and lubricating the machine.

- Inspecting the machine for wear and tear.

- Replacing worn or damaged parts.

- Troubleshooting common problems, such as tool breakage, coolant leaks, and electrical issues.

- Reporting any major issues to a supervisor.

4. Safety

Following all safety procedures and wearing appropriate safety gear to prevent accidents and injuries.

- Wearing appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Following all safety procedures, such as locking out the machine before performing maintenance.

- Reporting any unsafe conditions or practices to a supervisor.

Interview Tips

Preparing for an interview for a Turret Lathe Set Up Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, social media pages, and job postings.

- Visit the company’s website to learn about their history, products or services, and culture.

- Read through the job description carefully to identify the key responsibilities and qualifications required for the position.

- Look up the company on social media to see what employees are saying about the company and the work environment.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely during the interview.

- Write down a brief outline of your answer to each question.

- Practice saying your answers out loud so that you can become more comfortable with the delivery.

- Ask a friend or family member to conduct a mock interview with you.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the work environment. You should also arrive on time for your interview. Being punctual shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for the work environment.

- Plan your route to the interview ahead of time so that you can avoid getting lost or being late.

- Arrive at the interview location at least 15 minutes early so that you have time to check in and prepare for the interview.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. This means being able to articulate why you are interested in the position and why you believe you are the right person for the job. You should also be able to demonstrate a positive attitude and a willingness to learn and grow.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be enthusiastic and positive about your skills and experience.

- Show that you are interested in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Turret Lathe Set Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!