Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Turret Punch-Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Turret Punch-Press Operator so you can tailor your answers to impress potential employers.

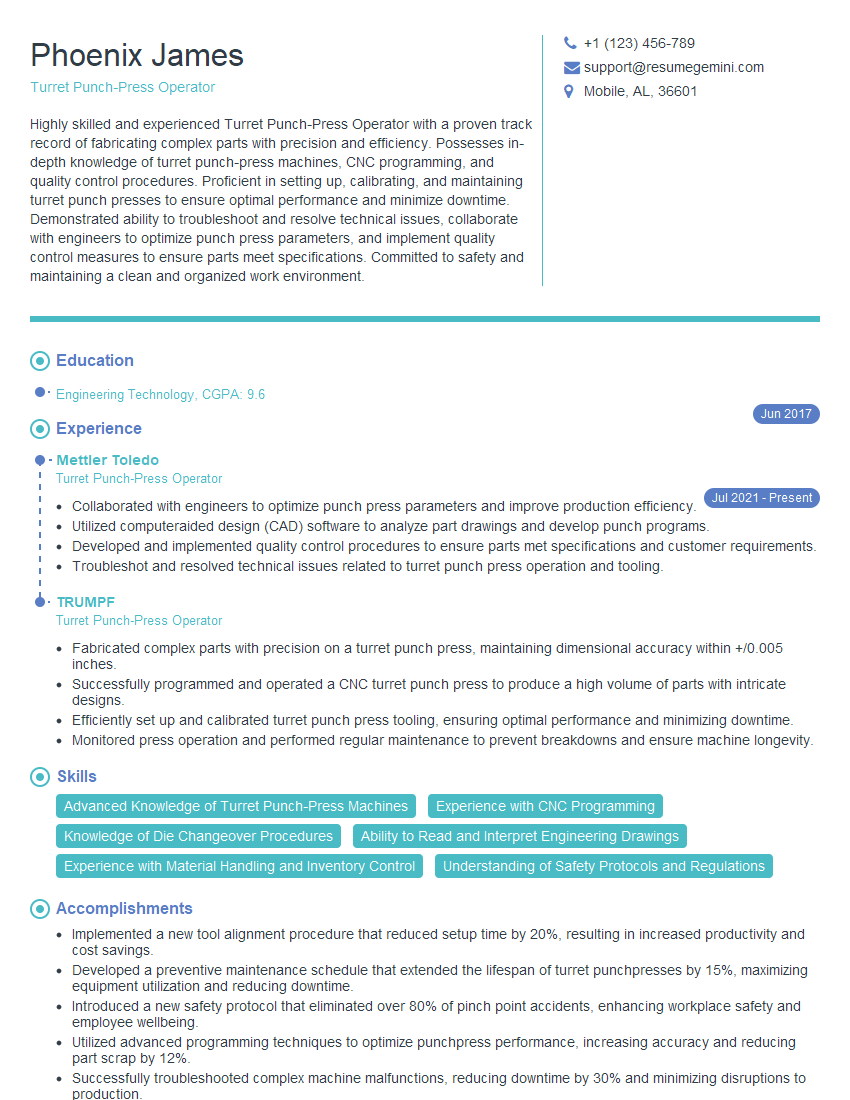

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turret Punch-Press Operator

1. What are the different types of turret punch presses?

There are two main types of turret punch presses: manual turret punch presses and CNC turret punch presses.

- Manual turret punch presses are operated by hand, while CNC turret punch presses are controlled by a computer.

- CNC turret punch presses are more accurate and efficient than manual turret punch presses, and they can be used to produce a wider variety of parts.

2. What are the different types of tooling used in turret punch presses?

Punching tools

- Round punches

- Square punches

- Rectangle punches

- Oval punches

- Hexagonal punches

Die sets

- Round dies

- Square dies

- Rectangle dies

- Oval dies

- Hexagonal dies

3. How do you set up a turret punch press?

To set up a turret punch press, you will need to follow these steps:

- Install the tooling.

- Set the punch and die clearance.

- Set the punch force.

- Set the feed rate.

- Calibrate the machine.

4. How do you operate a turret punch press?

To operate a turret punch press, you will need to follow these steps:

- Load the material into the machine.

- Position the material under the punch.

- Start the machine.

- Monitor the machine while it is running.

- Unload the finished parts from the machine.

5. What are the safety precautions that must be taken when operating a turret punch press?

When operating a turret punch press, you must take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if it is not properly guarded.

- Be aware of the potential hazards of the machine, and take appropriate precautions to avoid injury.

6. What are the common problems that can occur when operating a turret punch press?

Some of the common problems that can occur when operating a turret punch press include:

- Tooling problems, such as broken punches or dies.

- Material handling problems, such as material jams or misfeeds.

- Machine problems, such as electrical or mechanical failures.

- Safety problems, such as operator error or inadequate guarding.

7. How do you troubleshoot a turret punch press?

To troubleshoot a turret punch press, you will need to follow these steps:

- Identify the problem.

- Determine the cause of the problem.

- Fix the problem.

- Test the machine to make sure that the problem has been fixed.

8. What is the difference between a turret punch press and a laser cutter?

Turret punch presses and laser cutters are both used to cut metal, but they use different technologies.

- Turret punch presses use punches and dies to cut metal, while laser cutters use a laser beam to cut metal.

- Turret punch presses are generally faster and more accurate than laser cutters, but laser cutters can cut more complex shapes.

9. What is the future of turret punch press technology?

The future of turret punch press technology is bright. Turret punch presses are becoming increasingly automated and efficient, and they are being used to produce a wider variety of parts.

- One of the most significant trends in turret punch press technology is the development of new tooling materials.

- Another trend is the development of new control systems that are making turret punch presses easier to operate.

10. What are the career opportunities for turret punch press operators?

There are a variety of career opportunities for turret punch press operators. Some of the most common job titles include:

- Turret punch press operator

- CNC turret punch press operator

- Turret punch press setup technician

- Turret punch press maintenance technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turret Punch-Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turret Punch-Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turret Punch-Press Operators are highly skilled workers who utilize computer-controlled machinery to create metal components. They play a crucial role in manufacturing, ensuring that components meet precise specifications and contributing to the production of high-quality products.

1. Machine Operation

Operate turret punch press machines, ensuring optimal performance and productivity.

- Load and position metal stock, accurately aligning it for punching.

- Monitor machine operations, including tool selection, punch size, and pressing force.

2. Quality Control

Inspect finished parts to verify their compliance with specifications, identifying and correcting any deviations.

- Conduct dimensional and visual inspections, using precision measuring tools.

- Identify and resolve quality issues, implementing corrective actions as needed.

3. Tool Maintenance

Maintain and troubleshoot turret punch press tools, ensuring their longevity and effectiveness.

- Replace dull or damaged tooling, ensuring optimal cutting performance.

- Clean and lubricate tools to prevent wear and tear.

4. Production Optimization

Collaborate with production teams to improve efficiency and productivity, reducing waste and minimizing downtime.

- Identify and implement process improvements to enhance output.

- Monitor production metrics to optimize machine utilization and reduce lead times.

Interview Tips

To ace your interview for a Turret Punch-Press Operator position, it is essential to demonstrate a strong understanding of the job’s responsibilities and possess the necessary skills and experience. Here are some tips to help you prepare:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Understand the specific requirements of the turret punch-press operator role within that organization.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into the latest trends and technologies.

2. Highlight Your Skills and Experience

Emphasize your proficiency in operating turret punch press machines, quality control procedures, and tool maintenance. Quantify your accomplishments whenever possible, using specific metrics and examples.

- For instance, instead of simply stating “I inspect finished parts,” say “I conducted dimensional and visual inspections on over 1000 parts daily, achieving a 99.9% accuracy rate.”

3. Demonstrate Technical Expertise

Be prepared to discuss your understanding of turret punch press technology, tool selection, and process optimization. Showcase your ability to troubleshoot common issues and implement solutions.

- Explain how you have successfully identified and resolved quality problems in previous roles.

- Discuss your experience in optimizing production processes, resulting in increased efficiency or reduced downtime.

4. Practice Common Interview Questions

Prepare for common interview questions related to the role, including your strengths and weaknesses, your career goals, and your reasons for pursuing this specific position. Practice answering these questions concisely and professionally.

- For example, you might be asked, “What are your strengths as a Turret Punch-Press Operator?”

- In response, you could say, “My strengths include my attention to detail, my ability to work independently, and my commitment to producing high-quality work.”

5. Be Enthusiastic and Confident

During the interview, show your enthusiasm for the position and the opportunity to contribute to the company’s success. Maintain eye contact, have a positive attitude, and express your confidence in your abilities.

- Remember that the interviewer is not only looking for your technical skills but also for someone who is a good fit for the company’s culture.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Turret Punch-Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Turret Punch-Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.