Feeling lost in a sea of interview questions? Landed that dream interview for Twill Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Twill Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

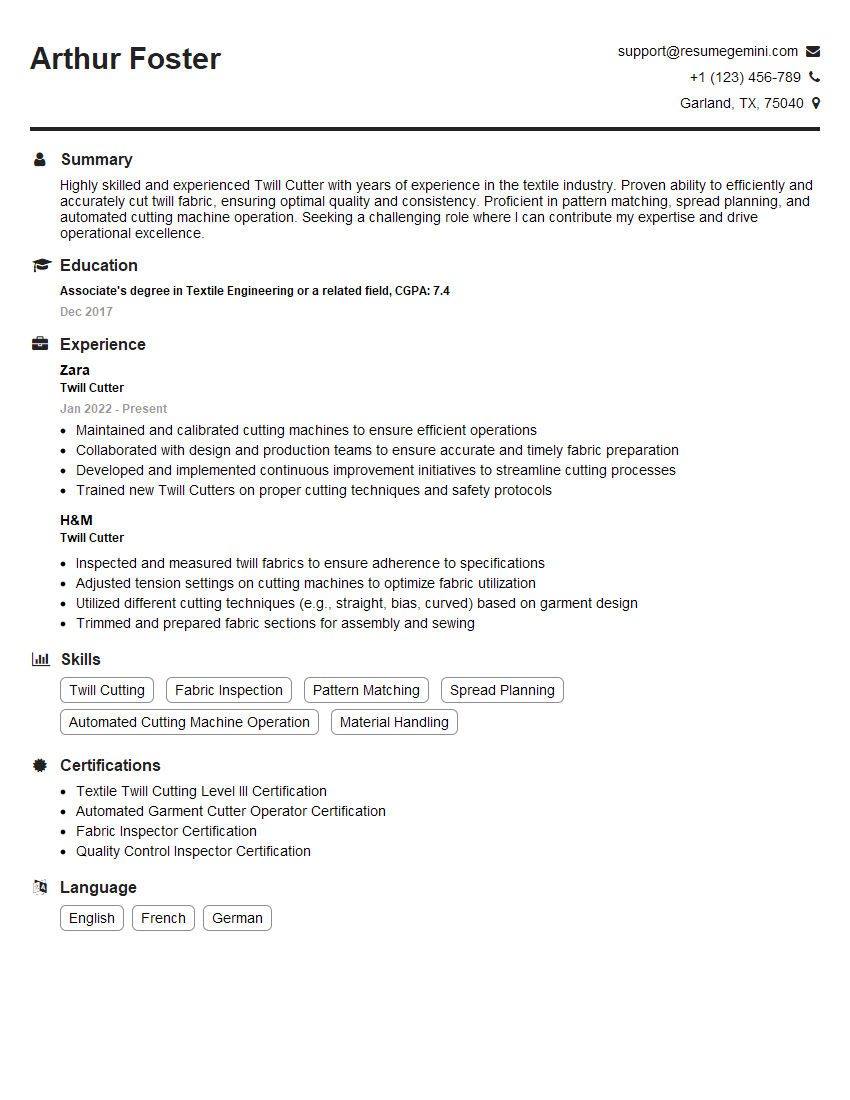

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Twill Cutter

1. What are the different types of twill weaves and how do they differ?

There are three main types of twill weaves: left-hand twill, right-hand twill, and herringbone twill.

- Left-hand twill is characterized by diagonal lines that run from the top left to the bottom right of the fabric. This type of twill is often used in denim and chino fabrics.

- Right-hand twill is characterized by diagonal lines that run from the top right to the bottom left of the fabric. This type of twill is often used in dress shirts and suits.

- Herringbone twill is a type of twill weave that creates a zigzag pattern on the fabric. This type of twill is often used in tweed and flannel fabrics.

2. What are the advantages and disadvantages of using twill fabric?

Advantages

- Twill fabric is durable and can withstand wear and tear.

- Twill fabric is wrinkle-resistant and easy to care for.

- Twill fabric is versatile and can be used in a variety of applications, from clothing to upholstery.

Disadvantages

- Twill fabric can be more expensive than other types of fabric.

- Twill fabric can be difficult to cut and sew.

3. What are some of the common uses for twill fabric?

Twill fabric is used in a wide variety of applications, including:

- Clothing (e.g., pants, shirts, dresses)

- Upholstery

- Curtains

- Bags

- Shoes

4. What are the different factors that affect the quality of twill fabric?

The following factors affect the quality of twill fabric:

- The type of fiber used

- The weave

- The finishing treatments

5. What are some of the latest trends in twill fabric?

Some of the latest trends in twill fabric include:

- The use of sustainable fibers, such as organic cotton and hemp

- The development of new and innovative weaves

- The use of digital printing to create unique and colorful designs

6. What are the different types of twill cutting machines?

There are three main types of twill cutting machines:

- Straight knife cutting machines

- Rotary knife cutting machines

- Laser cutting machines

7. What are the advantages and disadvantages of using a straight knife cutting machine?

Advantages

- Straight knife cutting machines are relatively inexpensive.

- Straight knife cutting machines are easy to operate.

- Straight knife cutting machines can cut a wide variety of materials.

Disadvantages

- Straight knife cutting machines can produce a rougher cut than rotary knife cutting machines.

- Straight knife cutting machines can be more difficult to control than rotary knife cutting machines.

8. What are the advantages and disadvantages of using a rotary knife cutting machine?

Advantages

- Rotary knife cutting machines produce a cleaner cut than straight knife cutting machines.

- Rotary knife cutting machines are easier to control than straight knife cutting machines.

- Rotary knife cutting machines can cut a wider variety of materials than laser cutting machines.

Disadvantages

- Rotary knife cutting machines are more expensive than straight knife cutting machines.

- Rotary knife cutting machines require more maintenance than straight knife cutting machines.

9. What are the advantages and disadvantages of using a laser cutting machine?

Advantages

- Laser cutting machines produce a very precise cut.

- Laser cutting machines can cut a wide variety of materials.

- Laser cutting machines are very fast.

Disadvantages

- Laser cutting machines are very expensive.

- Laser cutting machines require a lot of maintenance.

10. How do you choose the right twill cutting machine for your needs?

To choose the right twill cutting machine for your needs, you need to consider the following factors:

- The type of material you will be cutting

- The thickness of the material you will be cutting

- The precision of the cut you need

- The speed at which you need to cut

- Your budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Twill Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Twill Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Twill cutters are responsible for cutting fabric according to specifications, using a variety of tools and machines. They work in a fast-paced environment and must be able to produce high-quality work.

1. Inspect Fabric

Inspect fabric to ensure it meets quality standards, and identify any defects.

2. Measure and Mark Fabric

Measure and mark fabric according to specifications, using a variety of tools such as rulers, measuring tapes, and marking pens.

3. Cut Fabric

Cut fabric using a variety of tools such as shears, knives, and die cutters.

4. Inspect Cut Fabric

Inspect cut fabric to ensure it meets specifications, and identify any defects.

5. Maintain Equipment

Maintain equipment in good working condition, and perform minor repairs as needed.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will show the interviewer that you are interested in the opportunity and that you have taken the time to learn more about the company.

- Visit the company’s website.

- Read news articles and press releases about the company.

- Check out the company’s social media pages.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Arrive on Time

Punctuality is important, so make sure to arrive on time for your interview. Arriving late will reflect poorly on you and could cost you the job.

- Plan your route ahead of time and leave early to allow for traffic and parking.

- If you are running late, call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and genuine in your answers.

- Show the interviewer your personality.

- Be enthusiastic and positive.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Twill Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!