Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Twisting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Twisting Machine Operator so you can tailor your answers to impress potential employers.

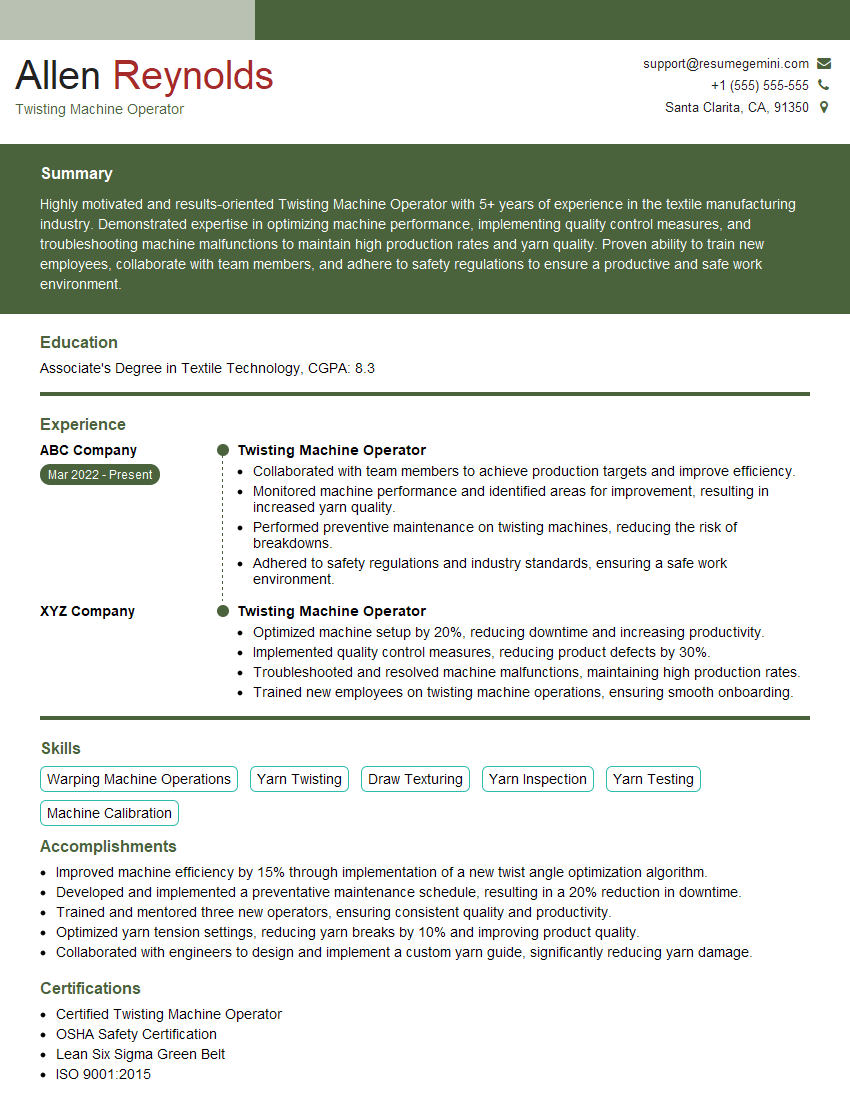

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Twisting Machine Operator

1. Describe the process of setting up a twisting machine for different types of yarn?

Answer:

- Analyze yarn specifications and determine appropriate twisting parameters (e.g., twist angle, wrap angle, feed rate).

- Adjust machine components, such as spindle speed, tension devices, and take-up reels, according to parameters.

- Load yarn packages onto the machine and ensure proper tension and alignment.

- Calibrate and test machine settings to ensure yarn quality and efficiency.

2. How do you troubleshoot and resolve common twisting machine issues, such as yarn breaks, uneven twist, and slack yarn?

Answer:

Troubleshooting Yarn Breaks:

- Check for excessive tension or insufficient lubrication.

- Inspect yarn packages for defects or knots.

- Adjust machine settings (e.g., feed rate, spindle speed) to optimize tension.

Resolving Uneven Twist:

- Verify that the spindle speed and wrap angle are set correctly.

- Check for worn or damaged spindle drive components.

- Recalibrate the machine and fine-tune settings.

Addressing Slack Yarn:

- Check for proper tension settings and yarn package alignment.

- Inspect take-up reels and ensure they are functioning properly.

- Adjust machine parameters to increase tension or reduce feed rate.

3. Explain the principles of yarn twisting and how it affects yarn properties?

Answer:

- Twisting involves imparting a helical angle to yarn strands, resulting in interlacing and increased cohesion.

- Increased twist angle enhances yarn strength and durability, reducing breakage susceptibility.

- Twisting also affects yarn bulk, handle, and elasticity.

- Optimal twisting parameters depend on the yarn material, end-use application, and desired properties.

4. Describe the different methods of twisting yarn and their respective advantages and disadvantages?

Answer:

Ring Twisting:

- Advantages: High production rates, uniform twist, good yarn quality.

- Disadvantages: High energy consumption, limited flexibility for fine yarns.

Open-End Twisting (Rotor Spinning):

- Advantages: Low energy consumption, high twist levels, suitable for short fibers.

- Disadvantages: Lower yarn strength, increased hairiness.

Double Twisting:

- Advantages: Enhanced strength and smoothness, reduced pilling.

- Disadvantages: Increased production cost, complexity of process.

5. How do you maintain and calibrate a twisting machine to ensure optimal performance?

Answer:

- Regularly clean and lubricate machine components.

- Monitor and adjust tension devices to prevent yarn breakage and ensure consistent quality.

- Calibrate spindle speed, twist angle, and wrap angle settings using precision instruments.

- Record and analyze machine data to identify areas for improvement and optimize performance.

6. Describe the safety precautions that must be observed when operating a twisting machine?

Answer:

- Wear appropriate safety gear, including gloves and eye protection.

- Secure loose clothing and jewelry to prevent entanglement.

- Never reach into the machine while it is operating.

- Keep work area clean and free from tripping hazards.

- Follow lockout/tagout procedures before performing maintenance or repairs.

7. Explain how you would calculate the twist multiplier for a given yarn?

Answer:

- Twist Multiplier (TM) = (Number of Twists per Inch) / (Yarn Count)

- Example: For a yarn with 10 twists per inch and a count of 20, the TM would be 10/20 = 0.5.

8. Describe the different types of twisting machines and their specific applications?

Answer:

Ring Twisting Machine:

- Used for producing high-quality yarns for apparel, home textiles, and industrial applications.

Open-End Twisting Machine (Rotor Spinning):

- Ideal for processing short fibers and producing yarns for low-cost applications, such as carpet and upholstery.

Two-for-One Twisting Machine (TFO):

- Used for doubling and twisting yarns to enhance strength, appearance, and performance.

9. How do you control yarn quality during the twisting process?

Answer:

- Monitor yarn tension and twist angle to ensure uniformity.

- Inspect yarn for defects, such as broken fibers, knots, and unevenness.

- Conduct regular testing to assess yarn strength, elongation, and other quality parameters.

- Make adjustments to machine settings or yarn feed as needed to optimize quality.

10. Describe your experience in working with different types of yarn, including their properties and processing challenges?

Answer:

- Experience working with natural fibers (e.g., cotton, wool, silk) and synthetic fibers (e.g., polyester, nylon).

- Understanding of yarn properties, such as fiber length, twist level, and elasticity.

- Ability to adjust twisting parameters based on yarn type and desired end-use.

- Experience in troubleshooting and resolving yarn defects related to different fiber types.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Twisting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Twisting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Twisting Machine Operators play a vital role in manufacturing processes. Their responsibilities include:Setting, operating, and maintaining twisting machines to twist fibers into yarns

1. Machine Operation

Executing operations of twisting machines swiftly and accurately

- Following instructions and specifications to set up and calibrate machines.

- Inspecting raw materials and ensuring they meet quality standards

2. Maintenance

Performing regular maintenance tasks and troubleshooting issues

- Conducting regular cleaning and lubrication.

- Monitoring machine performance and making adjustments when necessary.

3. Yarn Quality

Inspecting and monitoring yarn quality

- Measuring yarn twist, thickness, and tension.

- Identifying and addressing defects to ensure yarn quality.

4. Safety and Compliance

Ensuring a safe and compliant work environment

- Wearing appropriate safety gear and following safety protocols.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for an interview for a Twisting Machine Operator position requires careful consideration. Here are some tips to enhance your chances of success:

1. Research the Company and Position

Thoroughly research the company’s background, industry, and the specific role. This demonstrates your interest and eagerness to align with their objectives.

- Read the company website, annual reports, and industry news.

- Study the job description thoroughly to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating twisting machines. Additionally, highlight your understanding of yarn properties and quality control procedures.

- Quantify your accomplishments with specific metrics and examples.

- Tailor your resume and cover letter to showcase your most relevant qualifications.

3. Practice Common Interview Questions

Prepare for common interview questions related to twisting machine operation, yarn manufacturing, and quality control. Practice your answers to deliver clear and concise responses.

- Consider potential behavioral questions and prepare examples that demonstrate your teamwork, problem-solving skills, and attention to detail.

- Seek feedback from a friend or family member on your practice sessions.

4. Be Confident and Enthusiastic

Project confidence and enthusiasm throughout the interview. Show your passion for the role and your eagerness to contribute to the company’s success.

- Maintain eye contact, speak clearly, and present yourself professionally.

- Be prepared to ask thoughtful questions at the end of the interview to demonstrate your engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Twisting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!