Are you gearing up for a career in Tying Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tying Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

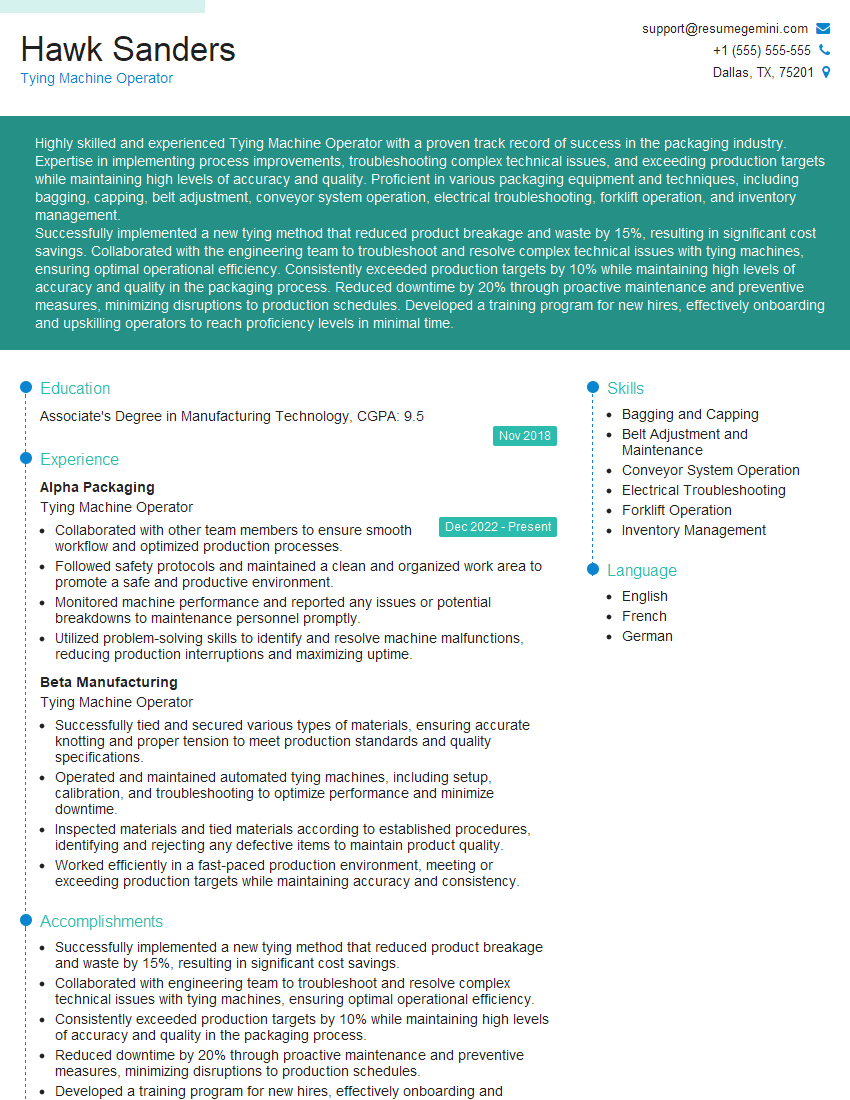

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tying Machine Operator

1. Explain the process of setting up a tying machine.

The process of setting up a tying machine involves several steps:

- Inspect the machine for any damage or defects.

- Clean and lubricate all moving parts.

- Install the tying head and spool.

- Thread the twine through the machine.

- Adjust the tension and speed settings.

- Test the machine to ensure proper operation.

2. What are the different types of knots that can be tied with a tying machine?

Types of knots:

- Square knot

- Bowline knot

- Slip knot

- Overhand knot

Factors affecting knot selection:

- Type of material being tied

- Strength and security required

- Speed and efficiency

3. How do you troubleshoot a tying machine that is not tying knots correctly?

Troubleshooting a tying machine that is not tying knots correctly involves identifying the root cause of the problem:

- Check the twine tension and adjust as needed.

- Inspect the tying head for wear or damage.

- Clean any debris or lint from the machine.

- Check the machine’s power supply.

- Refer to the manufacturer’s instructions for additional troubleshooting steps.

4. What are the safety precautions that should be taken when operating a tying machine?

To ensure safety when operating a tying machine, several precautions should be observed:

- Wear appropriate personal protective equipment, including gloves and eye protection.

- Keep hands and fingers away from the moving parts of the machine.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions and safety guidelines.

- Be aware of the surroundings and potential hazards.

5. How do you maintain a tying machine to ensure optimal performance?

Regular maintenance is crucial for optimal performance of a tying machine:

- Clean and lubricate all moving parts.

- Inspect the tying head and spool for wear or damage.

- Check the twine tension and adjust as needed.

- Keep the machine’s housing clean and free of debris.

- Follow the manufacturer’s recommended maintenance schedule.

6. What is the role of the tying machine in the overall production process?

The tying machine plays a vital role in the production process:

- It secures packaging materials and bundles.

- Ensures product stability and safety during transportation.

- Contributes to efficient and timely production.

- Improves the overall quality and presentation of packaged goods.

7. How would you handle a situation where the tying machine is not performing up to expectations?

To handle a situation where the tying machine is not performing up to expectations, I would follow these steps:

- Identify and assess the issue.

- Consult the manufacturer’s instructions or technical support.

- Perform basic troubleshooting and maintenance procedures.

- If necessary, escalate the issue to a supervisor or technician.

- Document the issue and any actions taken.

8. Describe how you use your knowledge of knots and tying techniques to optimize the performance of the tying machine.

I utilize my knowledge of knots and tying techniques to optimize the performance of the tying machine by:

- Selecting the appropriate knot for the specific application.

- Adjusting the machine’s tension and speed settings to achieve optimal results.

- Ensuring the twine is of the correct size and material for the desired knot.

- Monitoring the machine’s operation to identify any potential issues.

9. What is your experience with different types of tying machines?

Throughout my career, I have worked with various types of tying machines, including:

- Semi-automatic tying machines

- Fully-automatic tying machines

- Hand-held tying machines

- Heavy-duty tying machines

I have become proficient in operating, maintaining, and troubleshooting these machines.

10. What are your expectations for this role as a Tying Machine Operator?

As a Tying Machine Operator, I expect to:

- Operate and maintain tying machines efficiently.

- Ensure high-quality and consistent tying results.

- Troubleshoot and resolve issues related to tying machines.

- Contribute to the overall productivity and efficiency of the production line.

- Maintain a safe and clean work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tying Machine Operators are responsible for operating and maintaining tying machines, which are used to tie and bundle various materials, such as food products, construction materials, and textiles. The key job responsibilities of a Tying Machine Operator include:

1. Machine Operation

Operating tying machines to secure materials, maintaining a consistent tension and speed.

- Loading materials onto the machine and securing them in place.

- Adjusting machine settings to optimize tying performance.

2. Machine Maintenance

Performing regular maintenance on tying machines, including cleaning, lubrication, and minor repairs.

- Monitoring machine performance and identifying potential issues.

- Troubleshooting and resolving common machine malfunctions.

3. Materials Handling

Handling and moving materials efficiently to ensure a smooth production process.

- Ensuring materials meet quality standards and are free of defects.

- Inspecting finished products for accuracy and completeness.

4. Safety and Compliance

Adhering to safety regulations and following proper operating procedures.

- Wearing appropriate safety gear and utilizing safety equipment.

- Maintaining a clean and organized work area.

Interview Tips

To help you ace your interview for a Tying Machine Operator position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company you’re applying to and the specific Tying Machine Operator role. This will give you a better understanding of the company’s values, culture, and the responsibilities involved in the position.

- Review the company’s website, social media pages, and industry news articles.

- Read the job description carefully and identify the key skills and experience required.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact and value.

- Mention specific types of tying machines you’ve operated and the materials you’ve worked with.

- Describe your proficiency in machine maintenance and troubleshooting.

3. Showcase Safety Awareness

Safety is paramount in manufacturing environments. Emphasize your commitment to safety by highlighting your knowledge of safety regulations and your track record of maintaining a hazard-free work area.

- Discuss your experience with personal protective equipment (PPE) and safety protocols.

- Mention any safety certifications or training you have completed.

4. Prepare for Common Interview Questions

Familiarize yourself with common interview questions for Tying Machine Operators. Prepare thoughtful and specific answers that demonstrate your qualifications.

- Tell me about your experience operating tying machines.

- Describe a time you identified and resolved a machine malfunction.

- How do you ensure the quality of tied materials?

5. Practice and Get Feedback

Practice answering interview questions aloud to improve your delivery and confidence. Ask a friend, family member, or career counselor to role-play an interview with you and provide constructive feedback.

- Record yourself answering questions to identify areas for improvement.

- Seek feedback on your body language, tone, and the clarity of your responses.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tying Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tying Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.