Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Type Rolling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

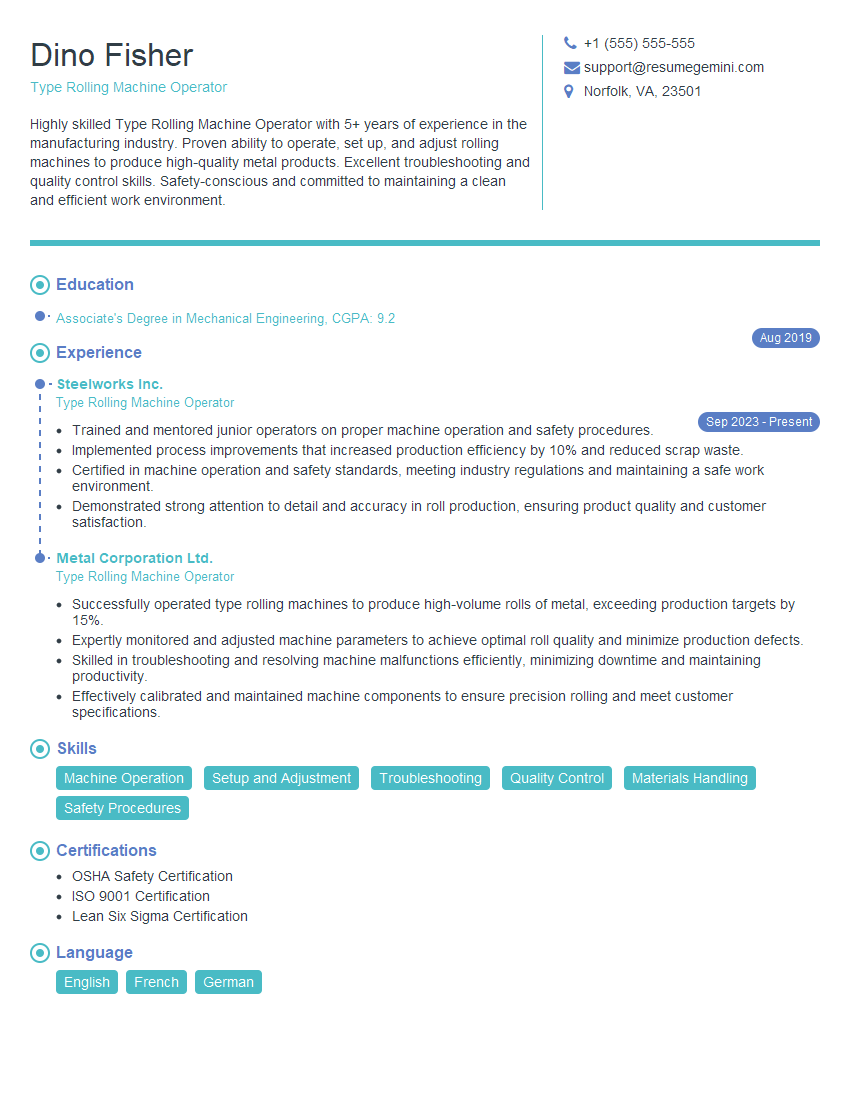

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Type Rolling Machine Operator

1. Explain the process of setting up a type rolling machine?

The process of setting up a type rolling machine involves the following steps:

- Inspecting the machine: Checking for any damage or wear and tear, ensuring all components are in working order.

- Mounting the type: Securing the type onto the machine’s bed, aligning it precisely for proper rolling.

- Adjusting the rollers: Setting the rollers to the desired size and pressure, ensuring they will produce the correct type size and depth.

- Positioning the ink fountain: Placing the ink fountain in the correct position and adjusting its flow rate to provide optimal ink coverage.

- Calibrating the machine: Running test rolls to ensure the machine is functioning properly, making any necessary adjustments to achieve desired results.

2. How do you ensure the quality of the type impressions?

Material Quality and Preparation

- Inspecting the paper or material used to ensure it meets specifications for thickness, smoothness, and moisture content.

Machine Maintenance and Calibration

- Regularly cleaning and lubricating the machine to prevent wear and tear, ensuring smooth operation.

- Calibrating the machine according to manufacturer’s specifications to maintain accurate type impressions.

Ink Quality and Application

- Using high-quality ink that is appropriate for the type of material being used.

- Adjusting the ink fountain settings to ensure optimal ink flow and coverage.

Monitoring and Inspection

- Continuously monitoring the rolling process to identify any deviations from the desired results.

- Performing regular inspections of type impressions to assess quality and make necessary adjustments.

3. Describe the different types of materials that can be used in type rolling?

- Paper: Various types of paper, including bond, ledger, and specialty papers, can be used.

- Cardboard and Corrugated Board: Different thicknesses and grades of cardboard and corrugated board are suitable for type rolling.

- Metal: Thin sheets of metal, such as aluminum or copper, can be used for type rolling with proper preparation.

- Plastic: Certain types of plastic, such as PVC or polycarbonate, can be used in type rolling, requiring specific techniques and settings.

- Other Materials: Type rolling can also be applied to leather, fabric, and wood under certain conditions.

4. How do you troubleshoot common problems that occur during type rolling?

- Uneven impressions: Check roller pressure, ink flow, and material quality.

- Blurred or smeared impressions: Inspect the type for damage, adjust roller pressure, and ensure proper ink viscosity.

- Ghosting: Check the machine’s calibration, adjust the impression depth, and inspect the material for moisture issues.

- Tearing or creasing of material: Adjust roller pressure, inspect the material for defects, and ensure the machine is properly aligned.

- Excessive ink usage: Check ink flow settings, inspect the ink fountain, and ensure the rollers are clean.

5. What maintenance procedures are required for a type rolling machine?

- Daily Checks: Inspecting the machine for any visible damage, cleaning the rollers and ink fountain, and lubricating moving parts.

- Weekly Maintenance: Calibrating the machine, adjusting the rollers and ink fountain settings, and checking the tension of belts and chains.

- Monthly Maintenance: Thorough cleaning of the machine, including the rollers, gears, and ink system, and replacing worn or damaged parts.

- Quarterly Inspections: Conducting a comprehensive inspection of the machine, including electrical components, safety features, and overall performance.

6. How do you ensure the safety of yourself and others while operating a type rolling machine?

- Following safety protocols: Adhering to established safety guidelines and procedures.

- Proper training: Receiving thorough training on the safe operation of the machine.

- Protective gear: Wearing appropriate protective gear, such as gloves and safety glasses.

- Guarding: Ensuring that all machine guards and safety features are in place and functioning properly.

- Awareness of surroundings: Staying alert to potential hazards in the work area and avoiding distractions.

7. Describe the different types of type rolling techniques?

- Letterpress: Impressing type directly onto paper using a raised metal or polymer type.

- Offset: Transferring the type impression to a rubber roller before printing it onto paper.

- Gravure: Etching the type design onto a metal cylinder, which then transfers the ink to paper.

- Flexography: Using flexible rubber or photopolymer plates to transfer the type impression to a variety of materials.

- Digital: Creating type impressions directly onto paper using digital printing technology.

8. How do you calculate the size and depth of the type impressions?

- Measuring the type: Using a caliper or magnifying glass to determine the height and width of the type.

- Adjusting the machine: Setting the rollers to the desired impression depth, considering factors such as material thickness and ink viscosity.

- Experimentation: Running test rolls to fine-tune the settings and achieve the desired results.

9. What factors affect the quality of type impressions?

- Type quality: The precision and condition of the type used.

- Machine condition: Proper maintenance and calibration of the type rolling machine.

- Ink quality: Using the appropriate ink for the type of material and rolling technique.

- Material quality: The thickness, smoothness, and moisture content of the material being used.

- Operator skill: The experience and attention to detail of the machine operator.

10. Describe the importance of maintaining accurate records in type rolling?

- Quality control: Tracking production data to identify trends and areas for improvement.

- Inventory management: Monitoring ink usage, type inventory, and material consumption.

- Machine maintenance: Recording maintenance schedules, repairs, and inspections.

- Customer service: Providing documentation for customer inquiries and resolving issues.

- Compliance: Meeting industry standards and regulations by maintaining accurate records.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Type Rolling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Type Rolling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Type Rolling Machine Operators are responsible for operating and maintaining type rolling machines, which are used to produce type for printing presses. They must have a strong understanding of the machine’s operation and be able to troubleshoot any problems that may arise.

1. Operate the type rolling machine

This involves setting up the machine, loading the type, and starting the rolling process. The operator must monitor the machine’s operation and make adjustments as needed to ensure that the type is rolled to the correct specifications.

2. Maintain the type rolling machine

This includes cleaning and lubricating the machine, as well as performing minor repairs. The operator must also inspect the machine regularly to identify any potential problems.

3. Inspect the type

The operator must inspect the type after it has been rolled to ensure that it meets the customer’s specifications. This includes checking the type for any defects, such as cracks or burrs.

4. Pack and ship the type

The operator must pack and ship the type to the customer. This includes packaging the type in a way that protects it from damage and shipping it using the appropriate method.

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips for acing an interview for a Type Rolling Machine Operator position:

1. Research the company and the position

Take some time to research the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture and the job’s responsibilities, and it will also show the interviewer that you’re genuinely interested in the position.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This doesn’t mean you have to wear a suit, but you should at least dress in clean, pressed clothing.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call or email the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Relax, be confident, and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Type Rolling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.