Are you gearing up for an interview for a Typesetter-Perforator Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Typesetter-Perforator Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

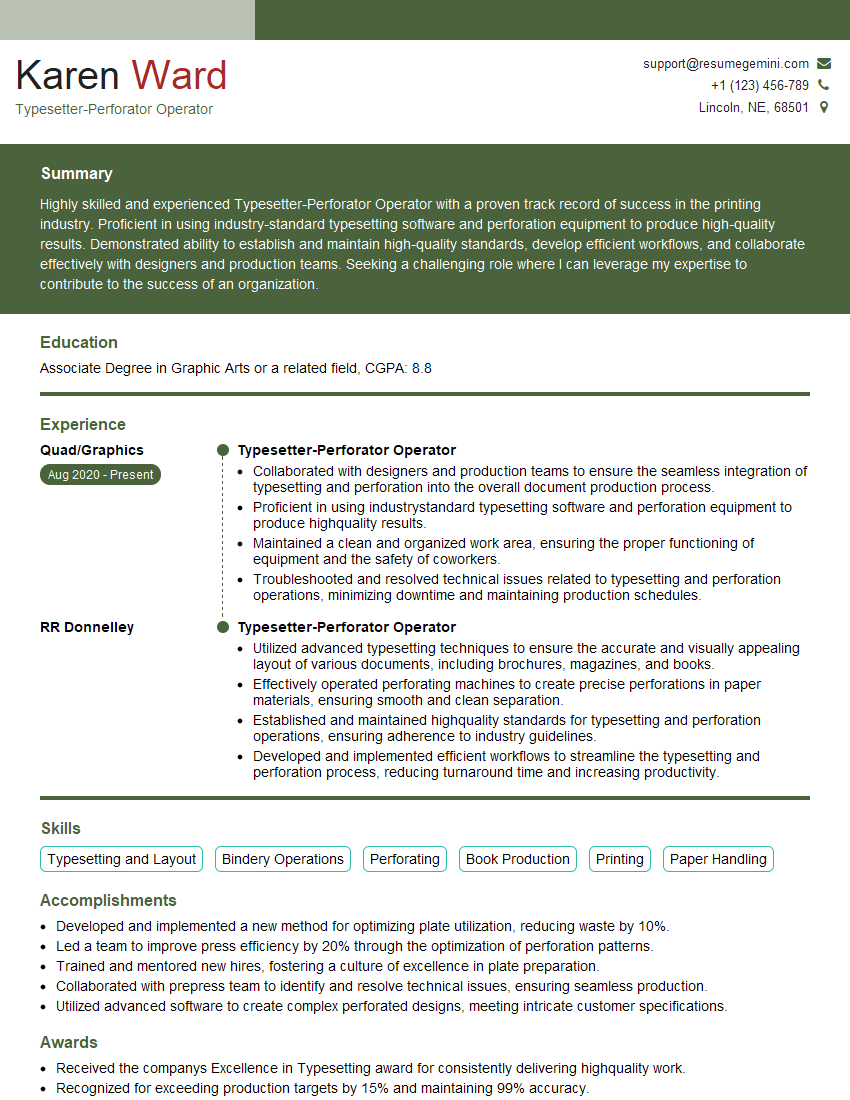

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Typesetter-Perforator Operator

1. Explain the process of typesetting and perforation?

Typesetting involves arranging and composing text and images to create a visually appealing and readable document. Perforation, on the other hand, is the process of creating a series of holes along the edges of paper or other materials to enable easy tearing or separation.

- In typesetting, I start by understanding the design requirements and preparing the text and images accordingly.

- I use specialized software to determine the appropriate font, page layout, and spacing, ensuring readability and visual appeal.

- For perforation, I set up the machine with the desired hole pattern and adjust the perforation speed and depth based on the material thickness.

- I carefully feed the material through the machine, ensuring accurate alignment and consistent perforation.

2. Describe the types of materials you have worked with as a Typesetter-Perforator Operator?

Paper and Cardstock

- Handled a wide range of paper types, including bond, coated, and specialty papers.

- Adjusted settings based on paper thickness and texture to achieve optimal results.

Plastic

- Perforated various plastic materials, such as PVC, polycarbonate, and PET.

- Considered material properties like thickness and melting point to ensure proper perforation.

Metal

- Worked with thin metal sheets, like aluminum and stainless steel.

- Used specialized perforation blades to create precise holes without compromising material integrity.

3. How do you ensure accuracy and precision in your work?

- I pay meticulous attention to detail and follow established procedures to minimize errors.

- I regularly calibrate and maintain the typesetting and perforation machines to ensure optimal performance.

- I conduct thorough inspections of the final products to identify and correct any imperfections.

- I collaborate with designers and other team members to clarify requirements and ensure project specifications are met.

4. Describe your experience with different types of typesetting software?

- I am proficient in Adobe InDesign, QuarkXPress, and Microsoft Word.

- I have used these software to create a variety of documents, including brochures, flyers, magazines, and books.

- I am familiar with their features and capabilities, enabling me to efficiently produce high-quality typeset materials.

5. How do you handle complex perforation patterns and tight deadlines?

- I carefully analyze complex perforation patterns to determine the optimal machine settings and blade selection.

- I prioritize tasks and allocate resources effectively to meet tight deadlines without compromising quality.

- I communicate regularly with clients and supervisors to keep them informed of progress and address any concerns promptly.

6. Have you worked with variable data perforation?

- Yes, I have experience using specialized software to generate variable data perforation patterns.

- I understand the importance of maintaining data integrity and ensuring accurate perforation for each individual item.

- I have successfully implemented variable data perforation for applications such as personalized direct mail campaigns and numbered tickets.

7. Describe your experience with troubleshooting and resolving issues related to typesetting and perforation?

- I am skilled in identifying and resolving common issues related to software glitches, machine malfunctions, and material defects.

- I have a systematic approach to troubleshooting, involving isolating the problem, identifying potential causes, and implementing appropriate solutions.

- I am committed to finding efficient and effective solutions to minimize downtime and maintain productivity.

8. How do you stay updated on the latest trends and technologies in the typesetting and perforation industry?

- I regularly attend industry conferences and workshops to learn about new techniques and equipment.

- I subscribe to trade publications and online forums to stay informed about industry best practices.

- I am eager to embrace technological advancements that enhance efficiency and accuracy in my work.

9. Can you provide examples of projects where your typesetting and perforation skills have made a significant impact?

- I worked on a project where I created intricate perforation patterns for a series of limited-edition art prints.

- The precise perforation enhanced the aesthetic appeal of the prints and made them easy to display.

- In another project, I used variable data perforation to create personalized membership cards for a large organization.

- The automated perforation process significantly reduced production time and ensured accuracy for each individual card.

10. What is your approach to teamwork and collaboration?

- I am a highly collaborative individual who enjoys working as part of a team.

- I am proactive in sharing knowledge and assisting my colleagues whenever possible.

- I am always willing to learn from others and contribute my own expertise to achieve common goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Typesetter-Perforator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Typesetter-Perforator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Typesetter-Perforator Operators are responsible for operating and maintaining typesetting and perforating machines, ensuring that printed materials are produced accurately and efficiently.

1. Preparation and Setup

Prepare and set up typesetting and perforating machines according to specifications by loading printing plates, ink, and paper.

- Adjust machine settings for paper size, margins, and font.

- Calibrate and maintain equipment to ensure optimal performance

2. Operation

Operate machines to typeset and perforate documents, ensuring that the final product meets quality standards.

- Monitor printing and perforating processes to identify and correct any errors or issues promptly.

- Make necessary adjustments to machine settings to optimize efficiency and quality

3. Finishing and Inspection

Perform finishing tasks such as folding, binding, and packaging printed materials.

- Inspect finished products for accuracy, completeness, and quality before distribution.

- Maintain a clean and organized work area to ensure a safe and efficient work environment

4. Maintenance

Perform routine maintenance and repairs on machines as necessary.

- Clean and lubricate equipment to prevent breakdowns and ensure longevity.

- Diagnose and troubleshoot machine issues promptly to minimize downtime

Interview Tips

Preparing for an interview for a Typesetter-Perforator Operator position requires a combination of technical knowledge, hands-on experience, and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will give you a better understanding of their products, services, and culture, and help you tailor your answers to their specific needs.

- Visit the company’s website and social media pages.

- Read industry publications and news articles about the company.

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview, and it will also allow you to provide more thoughtful and articulate responses.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers to behavioral interview questions.

- Practice answering questions about your experience, skills, and qualifications.

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you take the interview seriously.

- Wear business attire, such as a suit or dress pants and a button-down shirt.

- Arrive at the interview location 10-15 minutes early.

4. Be Enthusiastic and Positive

The interviewer wants to know that you are excited about the position and that you have a positive attitude. Be enthusiastic when you answer questions and be sure to highlight your skills and experience. However, avoid being over-the-top or pushy.

- Smile and make eye contact with the interviewer.

- Be confident in your answers and skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Typesetter-Perforator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!