Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ultrasonic Seaming Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ultrasonic Seaming Machine Operator so you can tailor your answers to impress potential employers.

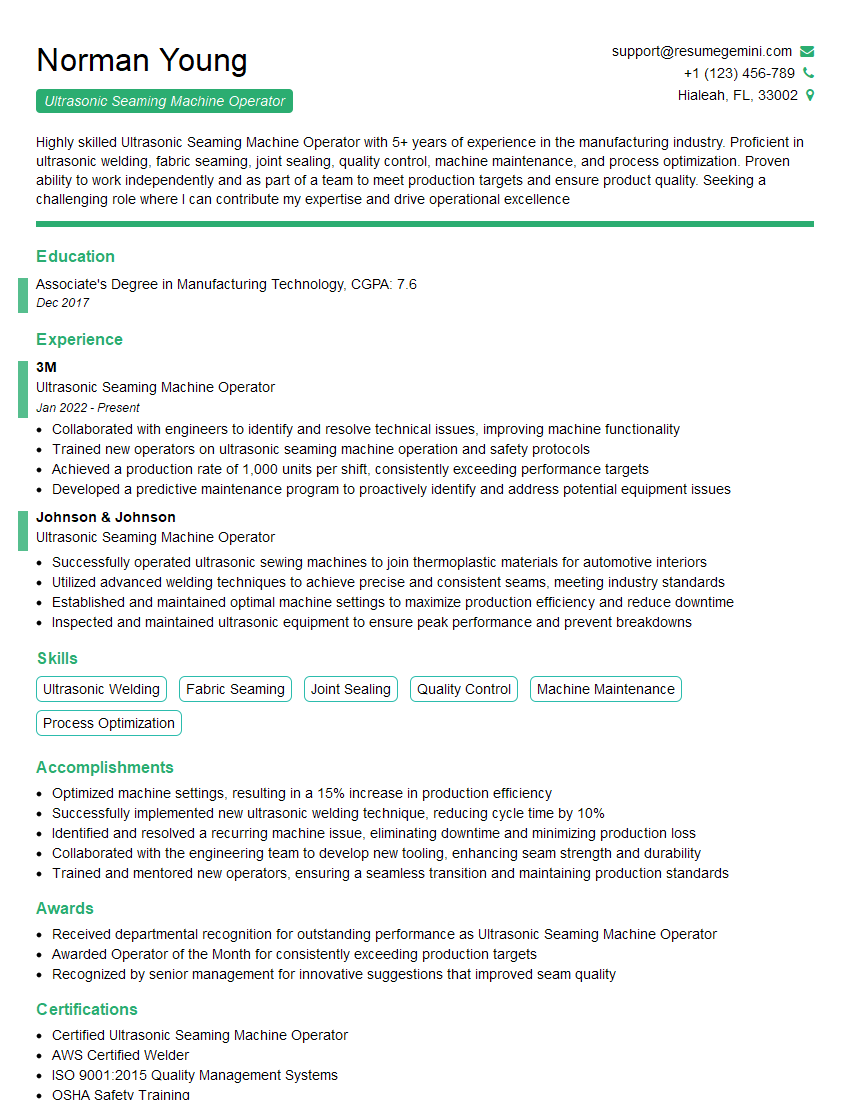

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ultrasonic Seaming Machine Operator

1. Explain the principle behind ultrasonic seam welding?

Ultrasonic seam welding is a solid-state bonding process that uses high-frequency ultrasonic vibrations to generate heat and friction at the interface of two thermoplastic parts. This heat and friction melt the plastic material, creating a strong bond between the two parts.

- High-frequency vibrations are generated by an ultrasonic transducer.

- These vibrations are transmitted to the welding horn, which is in contact with the plastic parts.

- The vibrations cause the plastic material to melt, creating a bond between the two parts.

2. What are the factors that affect the strength of an ultrasonic seam weld?

- The amplitude of the ultrasonic vibrations.

- The frequency of the ultrasonic vibrations.

- The welding time.

- The pressure applied to the welding horn.

- The type of plastic material being welded.

3. What are the advantages of using ultrasonic seam welding?

- Strong bond strength.

- Fast cycle times.

- No need for adhesives or other consumables.

- Minimal heat input, which reduces the risk of damage to the plastic parts.

- Clean and precise welds.

4. What are the disadvantages of using ultrasonic seam welding?

- High initial investment cost.

- Limited to thermoplastic materials.

- Can be noisy.

- Requires skilled operators.

5. What are the different types of ultrasonic seam welding machines?

- Continuous seam welding machines.

- Intermittent seam welding machines.

- Orbital seam welding machines.

6. What are the safety precautions that must be taken when operating an ultrasonic seam welding machine?

- Wear ear protection.

- Wear eye protection.

- Do not touch the welding horn while it is in operation.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s operating instructions.

7. How do you troubleshoot a problem with an ultrasonic seam welding machine?

Troubleshooting problems with an ultrasonic seam welding machine can be challenging, but there are a few general steps that you can follow:

- Check the power supply to the machine.

- Check the ultrasonic transducer for any damage.

- Check the welding horn for any damage.

- Check the welding parameters (amplitude, frequency, time, pressure).

- Check the plastic material being welded.

8. What are the maintenance requirements for an ultrasonic seam welding machine?

- Regularly clean the welding horn.

- Inspect the ultrasonic transducer for any damage.

- Check the welding parameters (amplitude, frequency, time, pressure).

- Calibrate the machine regularly.

- Follow the manufacturer’s maintenance instructions.

9. What are the quality control procedures for ultrasonic seam welding?

- Visual inspection of the weld.

- Destructive testing of the weld.

- Non-destructive testing of the weld.

- Statistical process control.

- Follow the customer’s quality specifications.

10. What is the future of ultrasonic seam welding?

Ultrasonic seam welding is a rapidly growing technology with a bright future. As the demand for lightweight and durable products increases, ultrasonic seam welding is expected to become even more popular.

- Development of new ultrasonic welding technologies.

- Increased use of ultrasonic welding in new applications.

- Improved quality control and process monitoring.

- Reduced costs and increased efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ultrasonic Seaming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ultrasonic Seaming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ultrasonic Seaming Machine Operator is responsible for operating and maintaining ultrasonic welding machines in the production of thermoplastic materials. They work in manufacturing facilities, using ultrasonic waves to join and bond thermoplastic materials without the use of adhesives or other bonding agents.

1. Machine Operation

The primary duty of an Ultrasonic Seaming Machine Operator is to operate Ultrasonic Seaming machines efficiently.

- Set-up and operate Ultrasonic Seaming machines according to job specifications.

- Adjust machine settings, including speed, power, and frequency.

- Monitor the machine during operation and make adjustments as needed.

- Troubleshoot and resolve machine malfunctions.

2. Fabric Handling

The operator is responsible for safely handling large amounts of fabric.

- Load and unload fabric materials from the machine.

- Inspect and prepare materials for processing.

- Ensure that materials meet specifications and are properly aligned.

3. Quality Control

Quality Control and Inspection are vital in this role.

- Inspect products for defects and non-conformances.

- Maintain quality control standards throughout the production process.

- Identify and resolve quality issues promptly.

4. Maintenance and Repair

The operator should perform routine maintenance and minor repairs on Ultrasonic Seamers.

- Perform regular maintenance and cleaning of machines.

- Conduct minor repairs, such as replacing parts or adjusting settings.

- Follow maintenance schedules and ensure machine uptime.

- Report major issues to supervisors for further action.

Interview Tips

To ace an interview for an Ultrasonic Seaming Machine Operator position, it is essential to prepare thoroughly and demonstrate your skills and qualifications. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role. You can gain valuable insights by visiting the company website, reading industry news, and checking social media pages.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you are likely to encounter during an interview for an Ultrasonic Seaming Machine Operator position. By practicing your answers to these questions, you can ensure that you deliver clear and concise responses. Some common interview questions include:

- Tell me about your experience operating Ultrasonic Seaming machines.

- How do you maintain quality control standards in your work?

- What are your strengths and weaknesses as an Ultrasonic Seaming Machine Operator?

- Why are you interested in working for our company?

- How do you handle working under pressure and meeting deadlines?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company. Some good questions to ask the interviewer include:

- What are the biggest challenges facing the Ultrasonic Seaming Machine Operator team currently?

- What is the company’s commitment to training and development?

- What are the opportunities for growth and advancement within the company?

- What is the company’s safety record and what measures are in place to ensure a safe work environment?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean and pressed business attire. It is also important to arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the position.

5. Follow Up After the Interview

After the interview, take the time to send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and to reiterate your interest in the position. You can also use the thank-you note to address any questions or concerns that you may have forgotten to mention during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ultrasonic Seaming Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ultrasonic Seaming Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.