Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ultrasonic Welding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

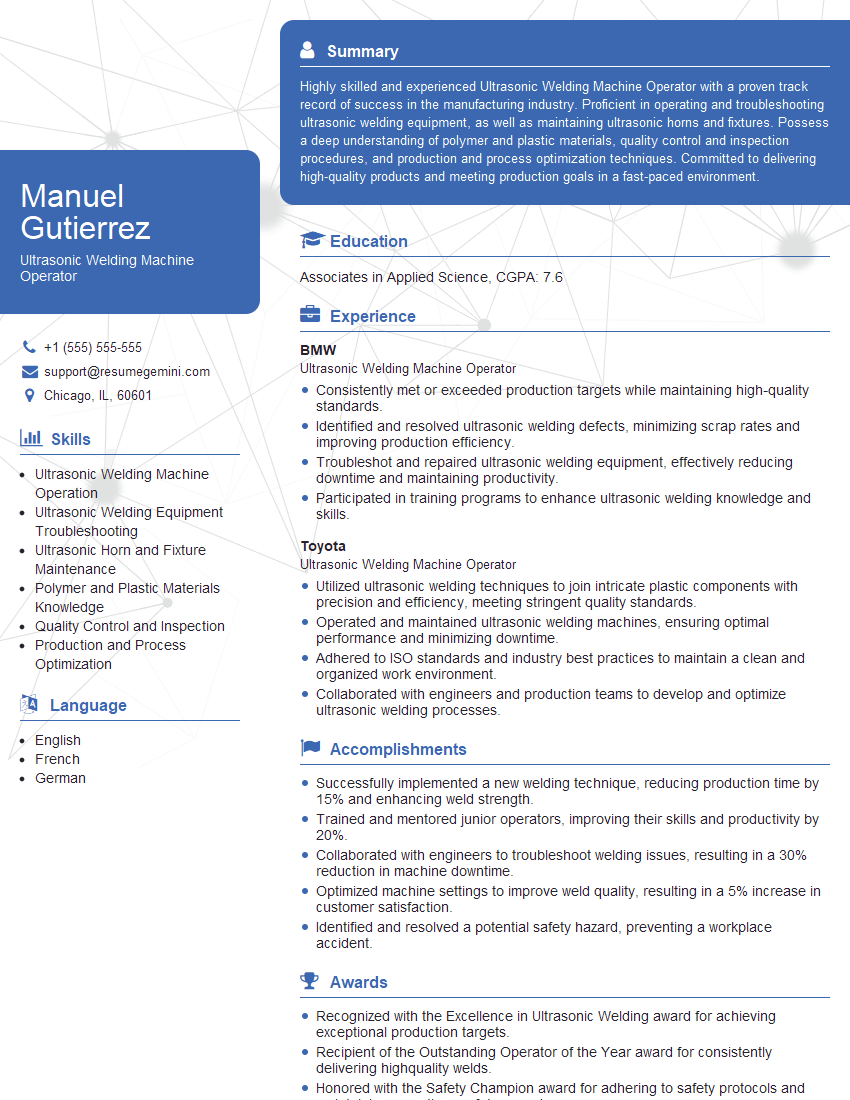

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ultrasonic Welding Machine Operator

1. Describe the working principles of ultrasonic welding?

Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic acoustic vibrations to weld thermoplastic materials. The process generates heat through friction at the interface of the two materials, causing them to melt and fuse together. The process is typically used to join thin, non-metallic materials such as plastics, fabrics, and films.

2. Explain the key parameters that affect the quality of ultrasonic welds?

Welding Amplitude

- The amplitude of the ultrasonic vibrations is a critical parameter that affects the weld quality. It determines the amount of energy that is transferred to the workpiece and the resulting weld strength.

Welding Time

- The welding time is the duration of the ultrasonic vibrations. It determines the amount of time that the materials are exposed to heat and pressure, which affects the weld strength and bond formation.

Welding Pressure

- The welding pressure is the force applied to the workpieces during welding. It helps to maintain contact between the materials and ensure proper energy transfer for welding.

Welding Frequency

- The welding frequency is the frequency of the ultrasonic vibrations. It affects the wavelength of the vibrations and the depth of penetration into the materials.

3. What are the common types of ultrasonic welding machines?

The two main types of ultrasonic welding machines are rotary ultrasonic welding machines and linear ultrasonic welding machines.

- Rotary ultrasonic welding machines use a rotating horn to generate ultrasonic vibrations. They are typically used for welding small, intricate parts.

- Linear ultrasonic welding machines use a linear actuator to generate ultrasonic vibrations. They are typically used for welding larger, flat parts.

4. What are the advantages and disadvantages of ultrasonic welding?

Advantages

- Fast and efficient welding process

- Produces strong and reliable welds

- Can be used to weld a wide variety of materials

- Does not require the use of adhesives or solvents

- Environmentally friendly process

Disadvantages

- Can be expensive to purchase and maintain

- Requires skilled operators to achieve optimal results

- Can produce noise and vibrations during operation

5. How do you troubleshoot common problems with ultrasonic welding machines?

Some common problems with ultrasonic welding machines include:

- Poor weld quality: This can be caused by a number of factors, including incorrect welding parameters, improper workpiece preparation, or a faulty welding horn.

- Machine overheating: This can be caused by a number of factors, including excessive welding time, insufficient cooling, or a faulty cooling system.

- Noise and vibration: This can be caused by a number of factors, including improper machine installation, a faulty welding horn, or worn bearings.

6. What are the safety precautions that should be taken when operating an ultrasonic welding machine?

- Wear ear protection to protect against noise.

- Wear eye protection to protect against flying debris.

- Keep hands away from the welding area.

- Do not operate the machine if it is not properly grounded.

- Follow all manufacturer’s instructions for safe operation.

7. How do you maintain an ultrasonic welding machine?

- Regularly clean the welding horn and anvil.

- Inspect the welding horn for wear and damage.

- Lubricate the bearings and other moving parts.

- Calibrate the machine regularly.

- Follow all manufacturer’s instructions for maintenance.

8. What are the different types of materials that can be welded using ultrasonic welding?

Ultrasonic welding can be used to weld a wide variety of materials, including:

- Thermoplastics

- Metals

- Composites

- Non-woven materials

9. What are the applications of ultrasonic welding?

Ultrasonic welding is used in a wide variety of applications, including:

- Automotive

- Medical

- Electronics

- Packaging

- Textiles

10. What are the career opportunities for ultrasonic welding machine operators?

Ultrasonic welding machine operators can find employment in a variety of industries, including manufacturing, automotive, and electronics.

- Entry-level operators typically start out by operating simple ultrasonic welding machines.

- With experience, operators can advance to more complex machines and applications.

- Some operators may also become supervisors or trainers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ultrasonic Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ultrasonic Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ultrasonic Welding Machine Operators are responsible for the safe and efficient operation of ultrasonic welding machines. They are required to have a strong understanding of the welding process and the equipment used to perform it. Some of the main responsibilities of an Ultrasonic Welding Machine Operator include:

1. Machine Setup and Operation

Setting up and operating the ultrasonic welding machine according to the specifications provided.

2. Maintaining Equipment

Maintaining the ultrasonic welding machine in good working condition by performing regular inspections and maintenance tasks.

3. Quality Control

Ensuring that the welds produced by the machine meet the required quality standards.

4. Troubleshooting

Troubleshooting and resolving any issues that may arise during the welding process.

Interview Tips

Preparing for an Ultrasonic Welding Machine Operator interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and the specific requirements of the role.

2. Highlight Relevant Experience

In your resume and during the interview, be sure to highlight any relevant experience you have with ultrasonic welding machines. If you have previous experience operating or maintaining these machines, be sure to mention it.

3. Demonstrate Technical Skills

The interviewer will want to assess your technical skills and knowledge of ultrasonic welding. Be prepared to answer questions about the welding process, the equipment used, and the quality standards required.

4. Show Enthusiasm and Motivation

Ultrasonic welding machine operators are often required to work independently and take initiative. Show the interviewer that you are enthusiastic about the role and are motivated to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ultrasonic Welding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!