Are you gearing up for a career in Under Cutting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Under Cutting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

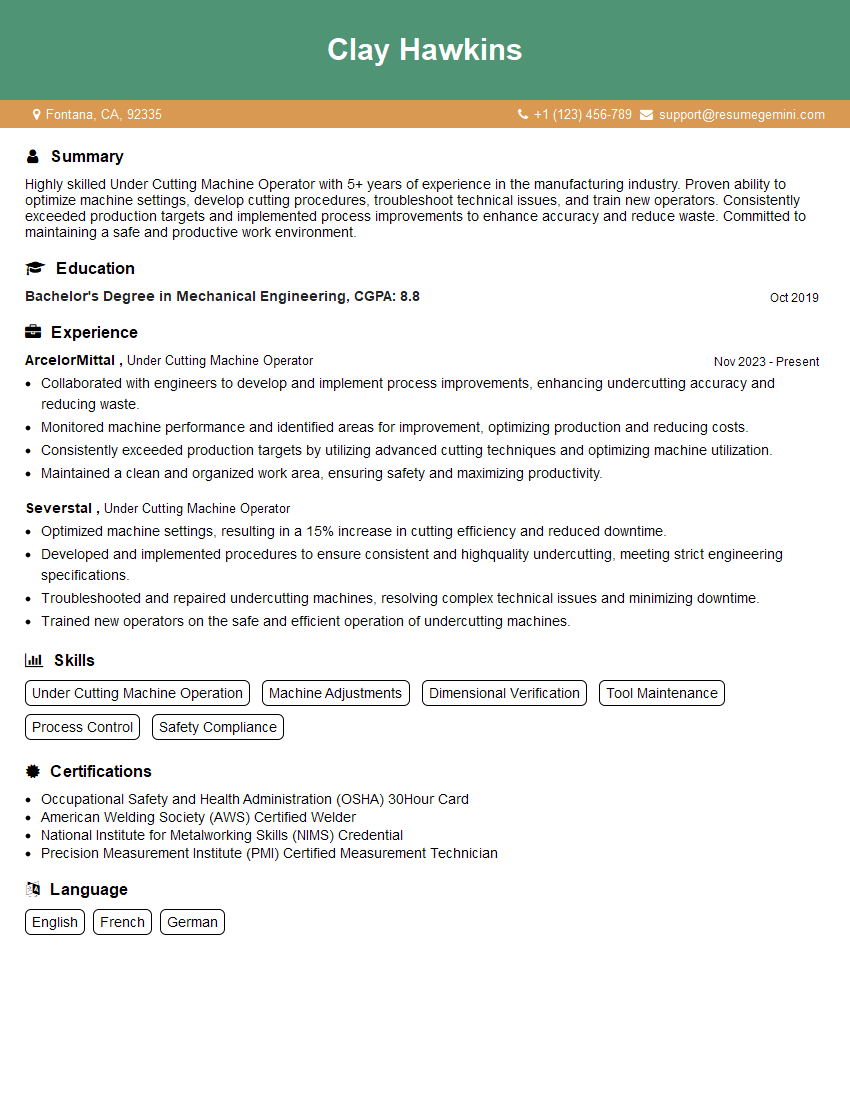

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Under Cutting Machine Operator

1. Describe the key responsibilities of an Under Cutting Machine Operator?

As an Under Cutting Machine Operator, I would be responsible for:

- Operating and maintaining under cutting machines to cut and trim materials.

- Setting up and adjusting the machine according to specifications.

- Ensuring that the machine is operating safely and efficiently.

- Inspecting materials for defects and making adjustments as needed.

- Maintaining a clean and organized work area.

- Following established safety procedures.

- Reporting any problems or concerns to the supervisor.

2. What are the different types of under cutting machines and their applications?

There are various types of under cutting machines, each with its own specific applications. Some common types include:

CNC Under Cutting Machine:

- Used for precise and complex cutting operations.

- Controlled by computer numerical control (CNC) system.

Manual Under Cutting Machine:

- Requires manual operation and control.

- Suitable for simple and straightforward cutting operations.

3. Can you explain the process of setting up and operating an under cutting machine?

The process of setting up and operating an under cutting machine involves several steps:

- Machine Setup:

- Install the appropriate cutting tool.

- Adjust the machine settings (speed, feed rate, depth of cut).

- Secure the material to be cut.

- Machine Operation:

- Start the machine and engage the cutting tool.

- Monitor the cutting process and make adjustments as needed.

- Stop the machine and retract the cutting tool once the cut is complete.

4. What are the safety precautions to be observed when working with under cutting machines?

To ensure safety when working with under cutting machines, the following precautions are crucial:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep hands and loose clothing away from the cutting area.

- Inspect the machine and cutting tools regularly.

- Follow established lockout/tagout procedures when servicing the machine.

- Never operate the machine under the influence of drugs or alcohol.

5. How do you maintain and troubleshoot under cutting machines?

Regular maintenance and troubleshooting are essential for optimal performance and safety:

Maintenance:

- Lubricate moving parts regularly.

- Sharpen or replace cutting tools as needed.

- Clean and inspect the machine thoroughly.

Troubleshooting:

- Identify the problem, such as poor cutting quality or machine malfunction.

- Check for loose connections, damaged parts, or incorrect settings.

- Make necessary adjustments or repairs.

6. What is your experience in working with different types of materials using under cutting machines?

I have experience in working with a variety of materials using under cutting machines, including:

- Metals (steel, aluminum, copper)

- Plastics (ABS, PVC, polycarbonate)

- Wood (hardwood, softwood, plywood)

I understand the specific cutting characteristics of each material and can adjust the machine settings accordingly to achieve optimal results.

7. Can you describe a challenging project you encountered as an Under Cutting Machine Operator and how you overcame it?

In a previous role, I encountered a challenging project where I needed to cut intricate shapes in thick metal sheets for a specialized equipment assembly.

- The task required precise cuts and tight tolerances.

- I carefully planned the cutting path and used specialized cutting tools to achieve the desired results.

- I also implemented quality control measures to ensure that each cut met the specified dimensions.

Through careful planning and execution, I was able to successfully complete the project on time and to the required specifications.

8. How do you stay updated with the latest advancements in under cutting machine technology?

To keep up with the latest advancements in under cutting machine technology, I take the following steps:

- Attend industry trade shows and conferences.

- Read technical publications and articles.

- Network with other Under Cutting Machine Operators and engineers.

- Participate in training and certification programs.

By staying informed about the latest technologies, I can optimize my skills and contribute to the overall efficiency and productivity of the organization.

9. What are your strengths and weaknesses as an Under Cutting Machine Operator?

Strengths:

- Excellent technical skills and understanding of under cutting machines.

- Strong attention to detail and commitment to quality.

- Ability to work independently and as part of a team.

- Excellent problem-solving and troubleshooting skills.

Weaknesses:

- Relatively new to the industry (can be turned into a strength with additional experience).

- Limited experience with certain specialized cutting techniques.

10. Why are you interested in working as an Under Cutting Machine Operator for our company?

I am eager to join your company as an Under Cutting Machine Operator because:

- Your company’s reputation for innovation and quality in the industry.

- The opportunity to contribute my skills to challenging projects.

- The chance to learn from experienced professionals and expand my knowledge.

- The company’s commitment to safety and employee development.

I am confident that I have the skills and dedication to be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Under Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Under Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Under Cutting Machine Operator is responsible for operating under cutting machines in order to shape and finish the bottoms of metal workpieces.

1. Machine Setup

The operator must ensure that the machine is properly set up for the job, including adjusting the cutting speed, feed rate, and depth of cut.

- Check the machine for any hazards or malfunctions.

- Load the workpiece into the machine and secure it.

2. Machine Operation

Once the machine is set up, the operator must operate it safely and efficiently.

- Start the machine and monitor it while it is running.

- Adjust the machine settings as needed to ensure that the cut is accurate and meets the desired specifications.

3. Inspection and Maintenance

The operator must inspect the finished workpieces to ensure that they meet the required specifications. The operator must also perform regular maintenance on the machine to keep it in good working order.

- Check the cut for accuracy and quality.

- Clean and lubricate the machine.

- Report any problems with the machine or the workpieces to the supervisor.

4. Safety

The operator must follow all safety regulations and procedures when operating the machine.

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of hazards.

- Be aware of the potential hazards of the machine and take steps to avoid them.

Interview Tips

To ace an interview for an Under Cutting Machine Operator position, it is important to be prepared and to be able to answer the interviewer’s questions clearly and concisely.

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is helpful to practice answering these questions in advance so that you can deliver them confidently and articulately.

- Use the STAR method to answer interview questions.

- Be prepared to talk about your experience and skills.

- Be honest and authentic in your answers.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in business casual attire.

- Be on time for your interview.

- Be polite and respectful to the interviewer.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be sure to convey your enthusiasm and positivity during the interview.

- Smile and make eye contact with the interviewer.

- Be positive and upbeat in your answers.

- Show the interviewer that you are interested in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Under Cutting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.