Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Underground Bolting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Underground Bolting Machine Operator so you can tailor your answers to impress potential employers.

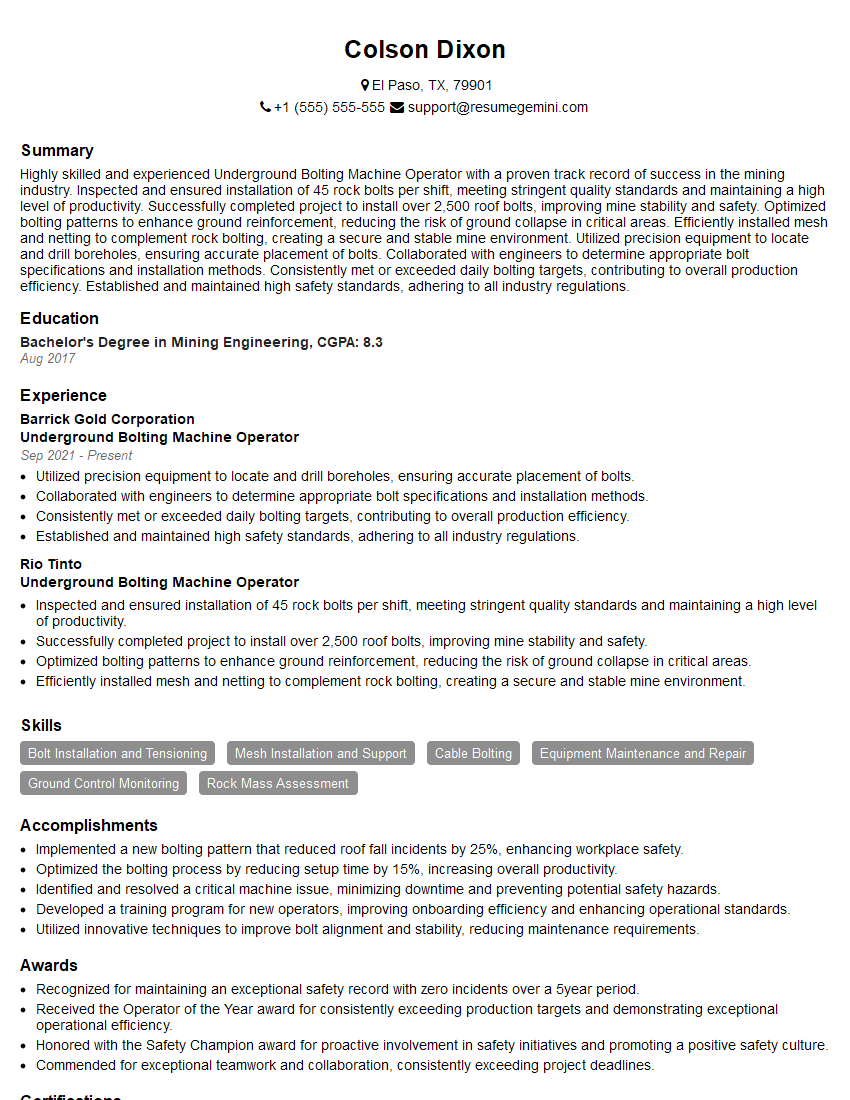

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Underground Bolting Machine Operator

1. Explain the key responsibilities and duties of an Underground Bolting Machine Operator?

As an Underground Bolting Machine Operator, I would be responsible for operating and maintaining a bolting machine to install rock bolts in underground mines or tunnels. My key responsibilities would typically include:

- Operating the bolting machine to drill holes for rock bolts.

- Inserting and tightening rock bolts to secure the roof, walls, and other areas of the underground excavation.

- Monitoring the bolting process to ensure the bolts are properly installed.

- Maintaining and servicing the bolting machine to keep it in good working condition.

- Following safety protocols and procedures to ensure a safe working environment.

2. Describe the different types of bolting machines you have experience operating?

Hydraulic Bolting Machines

- Hydraulic bolting machines use hydraulic pressure to power the drilling and bolting process.

- They are commonly used in underground mining and tunneling due to their power and efficiency.

Electric Bolting Machines

- Electric bolting machines use electricity to power the drilling and bolting process.

- They are often used in areas where there are concerns about hydraulic leaks or contamination.

3. How do you determine the proper bolt length and type for a particular application?

To determine the proper bolt length and type for a particular application, I would consider the following factors:

- Ground conditions: The strength and stability of the ground will influence the bolt length and type required.

- Bolt pattern: The spacing and arrangement of the bolts will also affect the bolt length and type.

- Safety regulations: Specific safety regulations may dictate the minimum bolt length and type that can be used.

4. What are the safety precautions you take when operating a bolting machine?

When operating a bolting machine, I prioritize the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and gloves.

- Inspecting the bolting machine before each use to ensure it is in good working condition.

- Following established safety protocols and procedures for operating the bolting machine.

- Being aware of my surroundings and taking precautions to avoid potential hazards.

- Communicating with other workers in the area to ensure coordination and avoid accidents.

5. How do you troubleshoot common problems that may occur with a bolting machine?

In case of common problems with a bolting machine, I would follow a systematic troubleshooting approach:

- Identify the problem: Observe the symptoms and identify the specific issue.

- Check for loose connections: Ensure that all electrical and hydraulic connections are secure.

- Inspect the drill bit: Check if the drill bit is dull or damaged and replace it if necessary.

- Lubricate the moving parts: Apply lubricant to the moving parts of the bolting machine to reduce friction.

- Consult the manufacturer’s manual: Refer to the manufacturer’s instructions for specific troubleshooting guidance.

6. How do you maintain and service a bolting machine to keep it in good working condition?

To maintain and service a bolting machine effectively, I would perform the following tasks:

- Regular cleaning: Clean the bolting machine regularly to remove dirt, debris, and other contaminants.

- Lubrication: Lubricate all moving parts of the bolting machine according to the manufacturer’s recommendations.

- Inspecting the hydraulic system: Check the hydraulic lines, hoses, and fittings for leaks or damage.

- Checking the electrical system: Inspect the electrical wiring, connections, and components for any issues.

- Preventive maintenance: Follow the manufacturer’s recommended maintenance schedule to prevent potential problems.

7. How do you work effectively as part of a team in an underground mining environment?

Working effectively as part of a team in an underground mining environment requires:

- Communication: Maintaining clear and regular communication with team members.

- Cooperation: Collaborating with others to achieve common goals.

- Problem-solving: Working together to identify and resolve issues.

- Safety awareness: Prioritizing safety and looking out for the well-being of team members.

- Respect: Treating team members with respect and valuing their contributions.

8. How do you stay updated on the latest techniques and technologies in underground bolting?

To stay updated on the latest techniques and technologies in underground bolting, I:

- Attend industry conferences and workshops: Participate in events that showcase new technologies and best practices.

- Read trade publications: Stay informed about industry trends and advancements by reading relevant publications.

- Network with other professionals: Connect with others in the field to exchange knowledge and learn about new developments.

- Research and experimentation: Explore new techniques and apply them in my work, while monitoring their effectiveness.

9. Describe your experience in working with different types of rock formations?

I have experience working with various types of rock formations, including:

- Sedimentary rocks: Sandstone, limestone, and shale.

- Igneous rocks: Granite, basalt, and andesite.

- Metamorphic rocks: Marble, slate, and gneiss.

Each type of rock formation requires different bolting techniques and considerations due to their varying strength, hardness, and geological characteristics.

10. How do you handle working in confined spaces and challenging underground conditions?

Working in confined spaces and challenging underground conditions requires specific skills and precautions. I approach such situations by:

- Risk assessment: Identifying potential hazards and implementing measures to mitigate them.

- Proper equipment: Using appropriate tools, machinery, and personal protective equipment (PPE).

- Ventilation and lighting: Ensuring adequate ventilation and lighting to maintain a safe and comfortable work environment.

- Communication: Maintaining regular communication with colleagues and supervisors.

- Emergency preparedness: Being aware of emergency procedures and having the necessary equipment on hand.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Underground Bolting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Underground Bolting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Underground Bolting Machine Operators play a critical role in ensuring the safety and stability of underground mines. Their primary responsibilities include:

1. Operating and Maintaining Bolting Equipment

Effectively operating and maintaining a variety of bolting machines, including roof bolters, rib bolters, and cable bolters.

- Installing and retrieving bolts and plates to secure the mine’s roof, ribs, and floor.

- Ensuring the equipment is in good working order and performing necessary maintenance and repairs.

2. Monitoring and Inspecting Underground Conditions

Constantly monitoring and inspecting the mine’s roof, ribs, and floor for signs of instability or hazardous conditions.

- Identifying and reporting any potential hazards or areas requiring bolting.

- Participating in regular inspections and surveys to assess the mine’s safety and stability.

3. Communicating with Mine Personnel

Effectively communicating with other mine personnel, including supervisors, engineers, and miners.

- Reporting observations, conditions, and any safety concerns.

- Coordinating bolting operations with other mining activities.

4. Ensuring Safety in the Workplace

Prioritizing safety in all aspects of their work.

- Following established safety protocols and procedures.

- Wearing appropriate protective gear and using proper bolting techniques.

5. Staying Updated on Industry Best Practices

Continuously seeking opportunities to enhance their knowledge and skills.

- Attending training programs and workshops.

- Staying informed about the latest industry best practices and technologies.

Interview Tips

Preparing for an interview for the position of Underground Bolting Machine Operator requires careful consideration. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, industry publications, and news articles to gain insights into their operations, safety culture, and commitment to sustainability.

- Demonstrate your understanding of the company’s position within the mining industry.

- Show that you are aware of the challenges and opportunities in the sector.

2. Highlight Your Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements. Clearly articulate your abilities in operating and maintaining bolting equipment, monitoring underground conditions, and prioritizing safety.

- Provide specific examples of your work experience that showcase your competence.

- Quantify your accomplishments whenever possible to demonstrate your impact.

3. Demonstrate Your Safety Consciousness

Throughout the interview, emphasize your unwavering commitment to safety. Explain your understanding of the importance of following safety protocols, wearing protective gear, and maintaining a safe work environment.

- Share examples of your proactive approach to identifying and mitigating hazards.

- Discuss your experience in participating in safety training and drills.

4. Express Your Desire for Continuous Improvement

Convey your eagerness to learn and grow in the field. Express your interest in attending training programs, reading industry publications, and staying updated on the latest best practices.

- Emphasize your commitment to continuous professional development.

- Discuss your aspirations for career advancement within the mining industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Underground Bolting Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Underground Bolting Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.