Are you gearing up for a career in Underground Heavy Equipment Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Underground Heavy Equipment Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

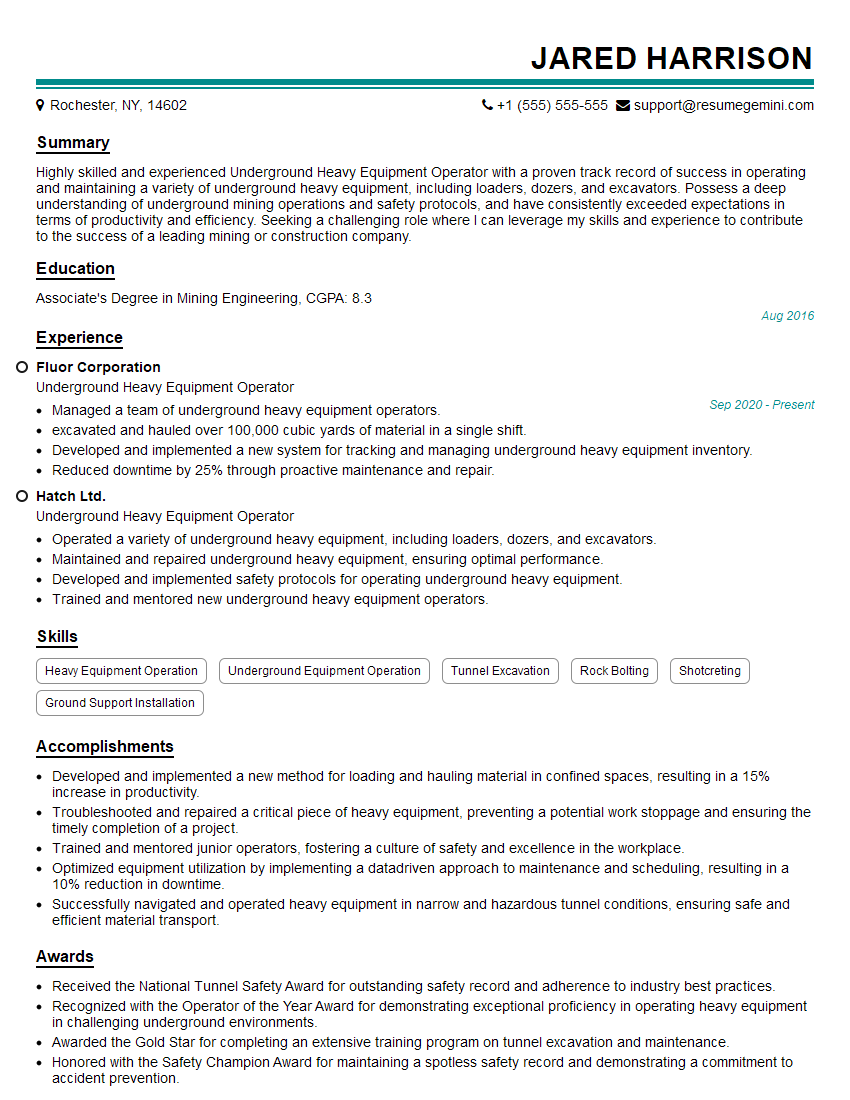

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Underground Heavy Equipment Operator

1. Explain the steps involved in preparing a work area for underground heavy equipment operation.

- Identify and mark underground utilities

- Clear obstacles and debris from the work area

- Set up barricades and warning signs

- Establish a safe access route for equipment

- Ensure adequate ventilation and lighting

2. Describe the safety precautions you take when operating underground heavy equipment.

Safe Equipment Operation

- Conduct pre-operation inspections

- Follow established operating procedures

- Maintain a safe distance from walls, roof, and other obstructions

- Use warning devices and communication systems effectively

Work Area Safety

- Be aware of ground conditions and potential hazards

- Stay alert and communicate with fellow workers

- Use appropriate personal protective equipment (PPE)

3. How do you maintain underground heavy equipment in good working condition?

- Regular inspections and maintenance schedules

- Lubrication, cleaning, and adjustments

- Repairs and replacements as needed

- Proper storage and handling techniques

- Following manufacturer’s instructions and recommendations

4. What are the signs of hydraulic system failure in underground heavy equipment?

- Unusual noises or vibrations

- Leaks or fluid loss

- Reduced hydraulic pressure or flow

- Difficulty in operating equipment

- Overheating or burning smell

5. How do you troubleshoot and repair electrical problems in underground heavy equipment?

- Identify the source of the problem

- Check wiring, connections, and components

- Use diagnostic tools and manuals

- Make necessary repairs or replacements

- Test and verify operation

6. Describe the importance of communication and teamwork in underground heavy equipment operation.

- Ensures safety and coordination

- Facilitates effective planning and execution

- Improves productivity and efficiency

- Builds trust and rapport among team members

- Creates a positive and supportive work environment

7. How do you handle working in confined spaces or hazardous environments?

- Follow established safety protocols

- Use appropriate PPE and equipment

- Monitor air quality and ventilation

- Maintain clear communication and escape routes

- Be aware of potential hazards and take necessary precautions

8. What are the challenges of working as an Underground Heavy Equipment Operator?

- Limited visibility and confined spaces

- Hazardous environments and potential for accidents

- Physical demands of heavy equipment operation

- Working in isolation or with limited supervision

- Maintaining knowledge and skills in a constantly evolving industry

9. How do you stay up-to-date with the latest technologies and best practices in underground heavy equipment operation?

- Attend industry workshops and conferences

- Read technical publications and online resources

- Consult with experienced operators and professionals

- Stay informed about advancements in equipment and safety protocols

- Participate in continuing education programs

10. Can you describe a situation where you had to use your problem-solving skills to resolve an issue while operating underground heavy equipment?

- Identified the problem and its potential causes

- Evaluated different solutions and their potential risks

- Implemented the chosen solution safely and effectively

- Monitored the results and made adjustments as needed

- Communicated the solution to other team members and supervisors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Underground Heavy Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Underground Heavy Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Underground Heavy Equipment Operators are responsible for the safe and efficient operation of heavy equipment in underground mining environments. They play a vital role in ensuring the smooth functioning of mining operations by transporting materials, constructing and maintaining underground infrastructure, and providing support to other workers.

1. Equipment Operation

Operate various types of heavy equipment, such as loaders, dozers, haul trucks, and excavators, to perform tasks such as:

- Transporting materials, including ore, waste rock, and supplies

- Constructing and maintaining roads, tunnels, and other underground structures

- Preparing excavation sites and loading materials into haul trucks

- Clearing debris and maintaining a safe working environment

2. Maintenance and Safety

Perform routine maintenance on heavy equipment to ensure it is in good working condition:

- Inspecting equipment for damage and wear

- Performing minor repairs and adjustments

- Maintaining equipment logs and records

- Following safety protocols to prevent accidents and injuries

3. Communication and Teamwork

Communicate effectively with other workers to coordinate activities and ensure smooth operations:

- Exchanging information with supervisors, engineers, and other equipment operators

- Reporting any equipment malfunctions or safety hazards

- Working as part of a team to achieve project goals

4. Record Keeping

Maintain accurate records of equipment usage, inspections, and maintenance activities:

- Documenting equipment hours, fuel consumption, and repairs

- Completing daily reports and logs

Interview Preparation Tips

Here are some tips to help you ace an interview for an Underground Heavy Equipment Operator position:

1. Research the Company and Position

Before attending an interview, take the time to research the mining company and the specific position you are applying for. This will help you understand the company’s operations, culture, and the key responsibilities of the role. You can gather information from the company’s website, social media pages, and industry publications.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers. You can use the key job responsibilities outlined above as a guide. Practice speaking clearly and concisely, providing specific examples to support your claims. It is also helpful to think about questions you may have for the interviewer, as this shows engagement and interest in the opportunity.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the position. Use examples from your previous roles to demonstrate your proficiency in operating heavy equipment, performing maintenance, and working safely in underground environments. If you have any certifications or licenses related to heavy equipment operation or mining, be sure to mention them.

4. Ask Thoughtful Questions

Asking well-thought-out questions at the end of the interview shows that you are interested in the position and have taken the time to prepare. Consider asking about the company’s safety protocols, training opportunities, or the specific challenges and rewards of working as an Underground Heavy Equipment Operator for that particular organization.

5. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. You can also use this opportunity to address any points that you may have forgotten to mention during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Underground Heavy Equipment Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.