Feeling lost in a sea of interview questions? Landed that dream interview for Unhairing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Unhairing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

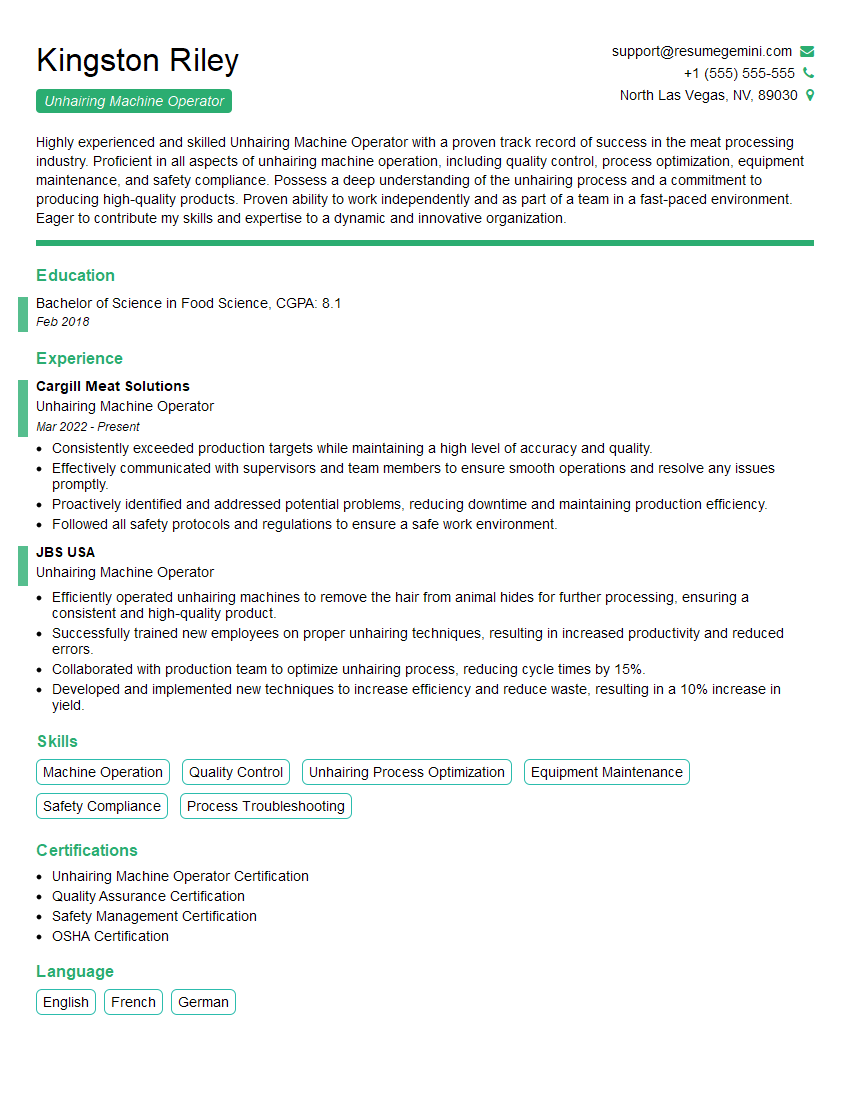

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Unhairing Machine Operator

1. What are the key responsibilities of an Unhairing Machine Operator?

Sample Answer:

- Operate and maintain unhairing machines to remove hair from animal hides.

- Adjust machine settings to ensure optimal hair removal and hide quality.

- Monitor the unhairing process and make necessary adjustments to maintain efficiency.

- Inspect hides after unhairing to ensure proper removal of hair and absence of defects.

- Clean and maintain unhairing machines and work area to ensure hygiene and safety.

2. Describe the different types of unhairing machines and their respective advantages and disadvantages.

Sample Answer:

Types of Unhairing Machines

- Drum Unhairing Machines:

- Uses revolving drums with rotating blades to remove hair.

- Advantages:

- High capacity

- Gentle on hides

- Disadvantages:

- Can damage hides if not operated properly

- Paddle Unhairing Machines:

- Uses paddles or beaters to agitate hides and remove hair.

- Advantages:

- More gentle on hides than drum machines

- Can be used for a variety of hides

- Disadvantages:

- Lower capacity than drum machines

- Enzyme Unhairing Machines:

- Uses enzymes to dissolve hair follicles, making hair easy to remove.

- Advantages:

- Produces high-quality hides

- Gentle on hides

- Disadvantages:

- Can be more expensive than mechanical unhairing methods

3. What are the most common problems that occur during the unhairing process and how do you address them?

Sample Answer:

- Hair not being completely removed: Adjust machine settings, increase unhairing time, or use different chemicals.

- Hides being damaged: Ensure proper machine operation, avoid over-unhairing, and handle hides carefully.

- Excessive foaming: Adjust the amount of chemicals used or add anti-foaming agents.

- Clogged machines: Clean machines regularly, remove hair buildup, and inspect for blockages.

- Poor hide quality: Identify the cause of the problem (e.g., hide condition, machine settings, chemicals) and make adjustments.

4. How do you ensure the safety of yourself and others while operating unhairing machines?

Sample Answer:

- Wear appropriate safety gear (e.g., gloves, aprons, safety glasses).

- Keep work area clean and free from hazards.

- Follow proper operating procedures and lock-out/tag-out machines before maintenance.

- Receive training on machine operation and safety protocols.

- Be aware of potential hazards and take precautions to mitigate risks.

5. What are the different types of chemicals used in the unhairing process and how do they affect the quality of the hides?

Sample Answer:

- Sodium sulfide: Dissolves keratin bonds, making hair easy to remove.

- Sodium hydroxide: Opens up hair follicles and assists in hair removal.

- Enzymes: Break down hair proteins, facilitating hair removal.

- Surfactants: Improve wetting and penetration of chemicals into hides.

- Anti-foaming agents: Reduce foaming, which can result in uneven hair removal.

6. What are the key factors that influence the efficiency of the unhairing process?

Sample Answer:

- Hide type and condition: Different hides require different unhairing methods and durations.

- Machine settings: Proper adjustment of speed, temperature, and chemical concentrations is crucial.

- Chemical quality: Using high-quality chemicals ensures effective unhairing.

- Machine maintenance: Regular cleaning and maintenance of machines prevents breakdowns and ensures optimal performance.

- Operator skill and experience: Skilled operators can optimize machine settings and troubleshoot problems efficiently.

7. How do you maintain the quality of the hides during the unhairing process?

Sample Answer:

- Minimize over-unhairing: Avoid leaving hides in the machine for extended periods.

- Use appropriate chemicals and concentrations: Follow manufacturer’s instructions for optimal results.

- Monitor hide condition during the process: Check for any signs of damage and adjust settings as needed.

- Handle hides carefully: Avoid unnecessary stretching or tearing.

- Conduct regular quality checks: Inspect hides after unhairing to ensure desired results.

8. What are the environmental and safety regulations that apply to the unhairing process?

Sample Answer:

- OSHA: Regulates workplace safety, including chemical handling and machine operation.

- EPA: Regulates the disposal of waste chemicals and wastewater.

- Local regulations: May impose specific requirements on the unhairing process and disposal practices.

- Industry best practices: Encourage environmental stewardship and worker safety.

9. How do you keep up with advancements in the field of unhairing?

Sample Answer:

- Attend industry conferences and workshops: Network with experts and learn about new technologies.

- Read trade publications and journals: Stay informed about industry trends and research.

- Consult with equipment manufacturers: Seek advice on best practices and emerging technologies.

- Participate in online forums and discussion groups: Connect with peers and share knowledge.

- Seek opportunities for training and professional development: Enhance skills and stay current with industry advancements.

10. What are your strengths and weaknesses as an Unhairing Machine Operator?

**Sample Answer:

Strengths:- Expertise in operating and maintaining unhairing machines: Years of experience in the field.

- Excellent knowledge of unhairing processes: Understanding of chemical reactions and hide quality maintenance.

- Strong attention to detail: Focus on ensuring optimal hair removal and hide quality.

- Teamwork and problem-solving skills: Collaborate with colleagues and troubleshoot issues efficiently.

- Commitment to safety and environmental compliance: Follow best practices and adhere to industry regulations.

- Limited experience with newer enzyme unhairing technologies: Willing to learn and adapt to advancements.

- Sometimes hesitant to make adjustments to machine settings without approval: Improving confidence in decision-making.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Unhairing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Unhairing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Unhairing Machine Operators are vital members of a tannery or leather processing facility, responsible for efficiently removing hair from animal hides to prepare them for further processing.

1. Machine Operation

The primary responsibility of an Unhairing Machine Operator is to operate and maintain the unhairing machine, ensuring it runs smoothly and efficiently throughout the production process.

- Monitor the machine’s operation, adjusting settings as needed to optimize performance.

- Troubleshoot and resolve any malfunctions or breakdowns promptly.

2. Hide Preparation

Before hides can be processed by the unhairing machine, they must be properly prepared to ensure effective hair removal.

- Inspect hides for defects or damage, flagging any that may require special attention.

- Load hides onto the machine’s conveyor system, ensuring they are positioned correctly for processing.

3. Quality Control

Unhairing Machine Operators play a crucial role in maintaining the quality of the finished leather products.

- Monitor the hair removal process, ensuring that hides are completely and uniformly dehaired.

- Inspect dehaired hides for any remaining hair or other imperfections, marking them for further processing or rejection as necessary.

4. Safety and Maintenance

The safety of the operator and those around them is paramount in any industrial setting.

- Adhere to all safety protocols and procedures, including wearing appropriate personal protective equipment.

- Perform regular maintenance on the unhairing machine, ensuring it is clean and in good working order.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can showcase your skills and land the job you desire. Here are some tips to help you ace your interview for an Unhairing Machine Operator position:

1. Research the Company and Role

Before the interview, take the time to research the tannery or leather processing facility you’re applying to. Understand their business operations, industry standing, and the specific requirements of the Unhairing Machine Operator role.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and news articles to stay up-to-date on current trends and best practices.

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job responsibilities. Showcase your proficiency in machine operation, hide preparation, quality control, and safety procedures.

- Quantify your accomplishments whenever possible, using specific examples to demonstrate your impact on previous roles.

- Be prepared to discuss your knowledge of different types of unhairing machines and the various techniques used in the hair removal process.

3. Demonstrate Your Commitment to Safety

Safety is a critical aspect of working as an Unhairing Machine Operator. In your interview, convey your unwavering commitment to following safety protocols and maintaining a clean and safe work environment.

- Share examples of your safety-conscious behavior in previous positions.

- Explain how you stay updated on the latest safety regulations and industry best practices.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your interest in the role and the company. It also gives you an opportunity to clarify any uncertainties and expand on your understanding of the position.

- Prepare questions about the company’s production process, quality standards, and environmental sustainability practices.

- Inquire about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Unhairing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!