Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Unionmelt Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

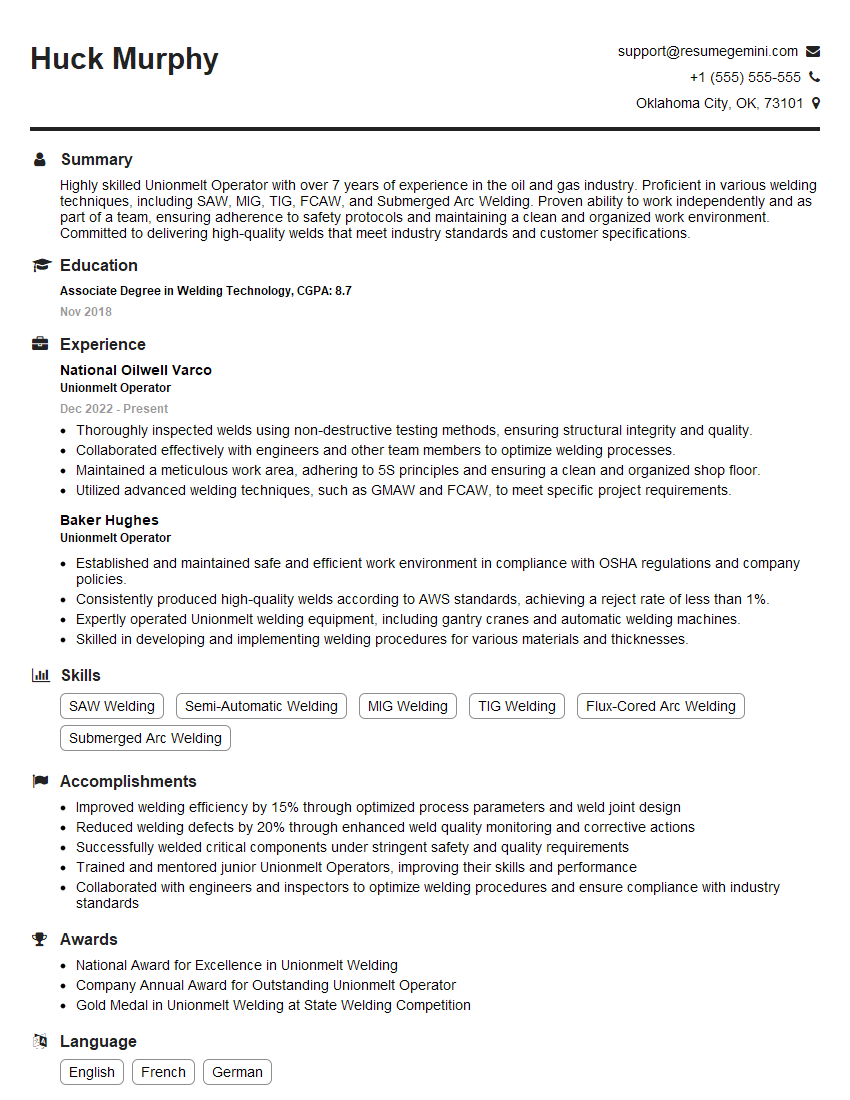

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Unionmelt Operator

1. Describe the process of setting up and operating a unionmelt welding machine?

- Inspect the welding machine and ensure it is in good working order.

- Mount the welding head onto the gantry and adjust the height and angle.

- Load the welding wire and flux into the machine.

- Set the welding parameters, such as the welding speed, voltage, and amperage.

- Start the welding process and monitor the weld pool to ensure proper penetration and fusion.

2. How do you maintain and troubleshoot a unionmelt welding machine?

Routine Maintenance

- Clean the welding head and nozzle regularly to prevent blockages.

- Inspect the welding wire and flux for any defects or contamination.

- Lubricate the moving parts of the machine, such as the gantry and welding head.

- Check the electrical connections and ensure they are tight and secure.

Troubleshooting

- If the weld pool is not properly penetrating, increase the welding speed or amperage.

- If the weld pool is too wide, decrease the welding speed or amperage.

- If the weld pool is too shallow, adjust the welding angle or use a different type of flux.

- If the welding wire is not feeding properly, check the wire guide and tension settings.

3. What types of joints can be welded using the unionmelt welding process?

- Butt joints

- Edge joints

- T-joints

- Corner joints

- Lap joints

4. What are the advantages and disadvantages of unionmelt welding?

Advantages

- High welding speeds

- Deep penetration and fusion

- Reduced distortion and residual stresses

- Good weld quality

- Automated process, reducing labor costs

Disadvantages

- Limited to flat or slightly curved surfaces

- High capital investment

- Requires a large amount of flux

- Can produce fumes and smoke

5. What are the safety precautions that must be taken when operating a unionmelt welding machine?

- Wear appropriate personal protective equipment, including a welding helmet, gloves, and clothing.

- Ensure the work area is well-ventilated to prevent fume inhalation.

- Handle the welding wire and flux carefully to avoid cuts or burns.

- Never touch the welding head or molten metal with bare hands.

- Be aware of the potential for electrical hazards and take appropriate precautions.

6. How do you calculate the welding speed for a unionmelt welding machine?

- Determine the desired weld thickness and penetration depth.

- Choose a welding wire diameter and type of flux.

- Set the welding current and voltage based on the welding wire diameter and flux type.

- Use the following formula to calculate the welding speed:

Welding Speed = (Welding Current x Welding Voltage) / (Weld Thickness x Penetration Depth)

7. What are the different types of fluxes used in unionmelt welding?

- Acidic fluxes: Used for welding low-carbon steels and produce a clean weld surface.

- Basic fluxes: Used for welding high-carbon steels and produce a stronger weld joint.

- Neutral fluxes: Used for welding stainless steels and produce a corrosion-resistant weld joint.

8. How do you control the amount of spatter when unionmelt welding?

- Use a welding wire with a low spatter index.

- Set the welding current and voltage to minimize spatter.

- Use a flux that contains anti-spatter agents.

- Maintain a proper welding distance between the welding head and the workpiece.

9. What are the different methods for starting and stopping a unionmelt welding machine?

Starting

- Manual start: The operator manually initiates the welding process by pressing a button.

- Automatic start: The welding process starts automatically when the welding head reaches the starting position.

Stopping

- Manual stop: The operator manually stops the welding process by pressing a button.

- Automatic stop: The welding process stops automatically when the welding head reaches the stopping position.

10. How do you adjust the welding parameters to achieve the desired weld quality?

- Adjust the welding speed to control the weld penetration and bead width.

- Adjust the welding current to control the weld penetration and heat input.

- Adjust the welding voltage to control the arc stability and weld bead shape.

- Adjust the flux type and amount to control the weld quality and spatter.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Unionmelt Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Unionmelt Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Unionmelt Operators are responsible for setting up, operating, and maintaining unionmelt welding machines. They ensure that the machines are operating at optimal levels, and troubleshoot and resolve any issues that may arise.

1. Setup and Operation

Unionmelt Operators are responsible for setting up the unionmelt welding machine according to the specified welding procedures. This includes installing the welding wire, setting the welding parameters, and positioning the welding torch. They also operate the machine to weld metals together, and monitor the welding process to ensure that the welds are of good quality.

- Install welding wire and set welding parameters

- Position welding torch and operate machine to weld metals

- Monitor welding process to ensure weld quality

2. Maintenance and Troubleshooting

Unionmelt Operators are also responsible for maintaining the unionmelt welding machine. This includes cleaning and lubricating the machine, and inspecting the machine for any signs of wear or damage. They also troubleshoot and resolve any issues that may arise with the machine, and make necessary repairs or adjustments.

- Clean and lubricate machine

- Inspect machine for wear or damage

- Troubleshoot and resolve machine issues

- Repair or adjust machine as needed

3. Safety and Compliance

Unionmelt Operators must also follow all safety procedures when working with the unionmelt welding machine. This includes wearing proper protective clothing and equipment, and following all lockout/tagout procedures. They must also be aware of the potential hazards of working with welding equipment, and take appropriate precautions to avoid accidents.

- Wear proper protective clothing and equipment

- Follow lockout/tagout procedures

- Be aware of potential hazards and take precautions

4. Communication and Teamwork

Unionmelt Operators often work with other team members, such as welders and fabricators. They must be able to communicate effectively with other team members, and work together to ensure that the welding project is completed on time and to the required specifications.

- Communicate effectively with team members

- Work together to complete welding projects

- Ensure projects are completed on time and to specifications

Interview Tips

Here are a few tips to help you ace your interview for a Unionmelt Operator position:

1. Research the company and the position

Take some time to learn about the company you’re interviewing with, and the specific position you’re applying for. This will help you answer questions about your qualifications and experience, and show the interviewer that you’re genuinely interested in the job.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance, so you can deliver them confidently and concisely.

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position, and to assess whether it’s a good fit for you.

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. Arrive on time, and be prepared to answer questions about your qualifications and experience.

Next Step:

Now that you’re armed with the knowledge of Unionmelt Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Unionmelt Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini