Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Universal Grinder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

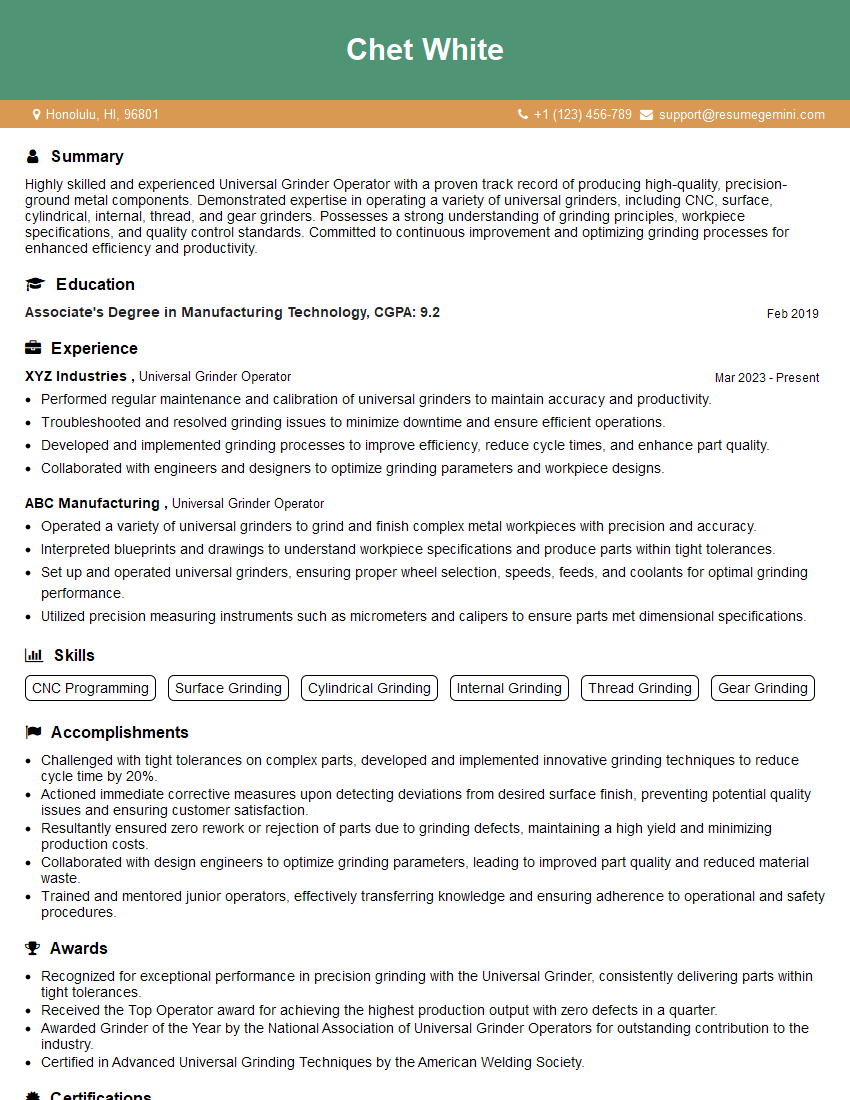

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Universal Grinder Operator

1. What are the different types of grinding machines and what are their applications?

- Surface grinders are used to produce flat surfaces on workpieces.

- Cylindrical grinders are used to grind the cylindrical surfaces of workpieces.

- Centerless grinders are used to grind the cylindrical surfaces of workpieces without the use of centers.

- Internal grinders are used to grind the internal surfaces of workpieces.

- Profile grinders are used to grind complex shapes into workpieces.

2. What are the different types of grinding wheels and what are their characteristics?

Abrasives

- Aluminum oxide: Hard and durable, used for grinding hard materials such as steel and cast iron.

- Silicon carbide: Sharper than aluminum oxide, used for grinding softer materials such as non-ferrous metals and ceramics.

- Cubic boron nitride: Very hard and durable, used for grinding hard materials at high speeds.

Bonding Agents

- Vitrified: Ceramic bond, strong and durable, used for heavy grinding.

- Resinoid: Organic bond, flexible and shock-resistant, used for light grinding and finishing.

- Metal: Metal bond, very strong and durable, used for heavy grinding of hard materials.

3. Describe the process of setting up a grinding machine for a specific job?

- Select the appropriate grinding wheel and mount it on the machine.

- Adjust the machine settings, such as the speed, feed rate, and depth of cut.

- Load the workpiece into the machine and secure it in place.

- Start the machine and grind the workpiece to the desired shape and finish.

4. Explain how to maintain a grinding machine to ensure optimal performance?

- Lubricate the machine regularly according to the manufacturer’s instructions.

- Clean the machine regularly to remove any grinding dust or debris.

- Inspect the grinding wheel regularly for wear or damage.

- Dress the grinding wheel as needed to maintain a sharp cutting edge.

5. What are the safety precautions that must be taken when operating a grinding machine?

- Always wear appropriate safety gear, such as eye protection, earplugs, and gloves.

- Never operate a grinding machine that is not properly guarded.

- Keep the work area clean and free of tripping hazards.

- Never leave a grinding machine running unattended.

6. Describe the different types of finishes that can be achieved with a grinding machine?

- Rough grinding: Produces a rough, unfinished surface.

- Semi-finish grinding: Produces a smoother, more refined surface.

- Finish grinding: Produces a very smooth, polished surface.

7. What techniques can be used to measure the accuracy of a ground surface?

- Vernier caliper: Measures the distance between two parallel surfaces.

- Micrometer: Measures the thickness of a workpiece.

- Dial indicator: Measures the runout of a workpiece.

8. Describe the relationship between the grinding wheel speed and the surface finish of a workpiece?

9. What factors affect the life of a grinding wheel?

- Material being ground

- Hardness of the material

- Grain size of the grinding wheel

- Speed of the grinding wheel

- Feed rate

- Depth of cut

10. What are the different types of coolants used in grinding and what are their advantages and disadvantages?

Water-based Coolants

- Advantages: Inexpensive, readily available, good cooling properties.

- Disadvantages: Can rust and corrode the workpiece, can cause staining.

Oil-based Coolants

- Advantages: Good lubrication properties, prevents rust and corrosion, can improve surface finish.

- Disadvantages: More expensive, can be flammable, can be difficult to dispose of.

Synthetic Coolants

- Advantages: Good cooling and lubrication properties, non-flammable, easy to dispose of.

- Disadvantages: More expensive than water-based or oil-based coolants.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Universal Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Universal Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Universal Grinder Operators play a crucial role in manufacturing by operating and maintaining specialized machines that shape and finish metal components with high precision.

1. Machine Operation

Proficiently operate universal grinders to perform various grinding operations such as cylindrical grinding, surface grinding, internal grinding, and taper grinding.

- Interpret blueprints and work orders to determine the required grinding parameters.

- Select and install the appropriate grinding wheels and accessories.

- Load, position, and secure workpieces on the machine.

- Adjust and monitor grinding parameters to achieve desired surface finishes and dimensional tolerances.

2. Quality Control

Inspect and measure ground components to ensure they meet specifications and quality standards.

- Perform in-process and final inspections using precision measuring instruments like calipers, micrometers, and coordinate measuring machines (CMMs).

- Identify and correct deviations from specified tolerances.

- Maintain detailed records of grinding operations and inspection results.

3. Machine Maintenance

Conduct routine maintenance and repairs on universal grinders to ensure optimal performance.

- Clean and lubricate machine components regularly.

- Change worn or damaged parts.

- Perform preventive maintenance tasks to avoid breakdowns.

- Troubleshoot and resolve machine malfunctions.

4. Safety Compliance

Adhere to safety regulations and protocols to ensure a safe work environment.

- Wear proper personal protective equipment (PPE).

- Operate machines safely and avoid hazardous conditions.

- Report any safety concerns or incidents immediately.

Interview Tips

Preparing for a Universal Grinder Operator interview requires a combination of technical knowledge, practical experience, and professional presentation skills.

1. Research the Company and Role

- Familiarize yourself with the company’s products, services, and industry standing.

- Thoroughly review the job description to understand the specific requirements and responsibilities.

- Visit the company website and LinkedIn page to gain insights into their culture and values.

2. Highlight Your Technical Skills

- Emphasize your proficiency in operating universal grinders and performing various grinding operations.

- Showcase your knowledge of grinding principles, including wheel selection, surface finishes, and dimensional tolerances.

- Demonstrate your ability to use precision measuring instruments and interpret technical drawings.

3. Showcase Your Problem-Solving Abilities

- Provide examples of situations where you successfully identified and resolved machine malfunctions or quality issues.

- Explain how you approach and solve problems systematically and efficiently.

- Highlight your analytical thinking and troubleshooting skills.

4. Emphasize Your Safety Awareness

- Stress your commitment to safety and your understanding of safe operating procedures.

- Describe your experience in following safety regulations and minimizing risks in the workplace.

- Explain how you proactively identify and mitigate potential hazards.

5. Practice Your Presentation

- Prepare clear and concise answers to common interview questions.

- Rehearse your responses to ensure fluency and confidence.

- Seek feedback from a mentor, friend, or family member to improve your delivery and communication skills.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Universal Grinder Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.