Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Upkeep Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

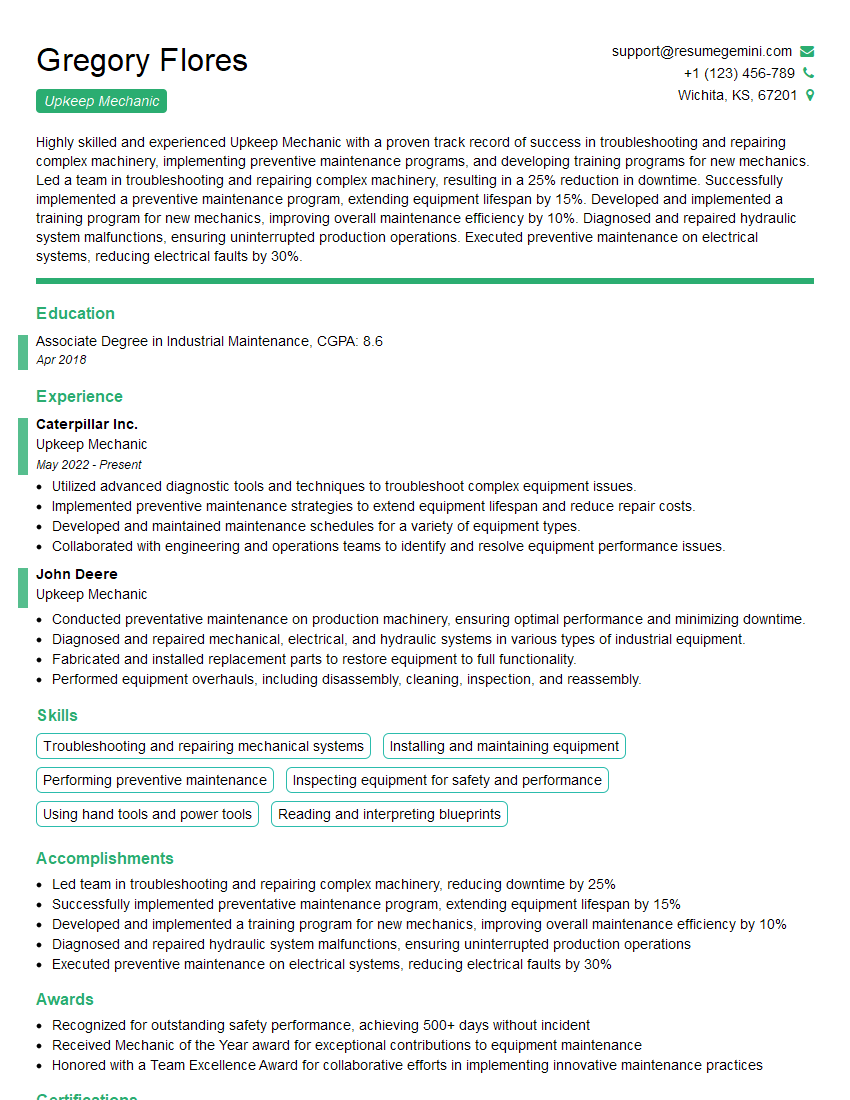

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Upkeep Mechanic

1. How would you troubleshoot a hydraulic system that is not holding pressure?

- Inspect the hydraulic lines and fittings for any leaks or loose connections.

- Check the hydraulic pump for any signs of damage or wear.

- Test the pressure relief valve to ensure it is functioning properly.

- Inspect the hydraulic accumulator for any leaks or damage.

- Check the hydraulic fluid level and condition.

2. What are the steps you would take to inspect and maintain a conveyor system?

Daily Inspections

- Check for any loose or damaged components.

- Inspect the belt for any signs of wear or damage.

- Check the bearings for any signs of wear or excessive noise.

- Lubricate all moving parts as per the manufacturer’s recommendations.

Weekly Inspections

- Check the tension of the belt.

- Inspect the pulleys for any signs of wear or damage.

- Check the alignment of the conveyor system.

- Clean the conveyor system of any debris.

Monthly Inspections

- Inspect the electrical components of the conveyor system.

- Check the hydraulic system for any leaks or contamination.

- Perform a full load test on the conveyor system.

- Document all inspections and maintenance activities.

3. What are the different types of welding processes and which one would you use to repair a cracked metal frame?

- Arc Welding: Uses an electric arc to melt the metal and create a weld pool. This process is commonly used for repairing thick metal frames.

- MIG Welding: Uses a continuous wire electrode and shielding gas to create a weld pool. This process is faster and easier to use than arc welding, making it suitable for repairing thinner metal frames.

- TIG Welding: Uses a non-consumable tungsten electrode and shielding gas to create a weld pool. This process provides a high-quality weld but requires more skill and experience to operate.

- Oxy-acetylene Welding: Uses a mixture of oxygen and acetylene gas to create a flame that melts the metal and creates a weld pool. This process is less common but can be used for repairing thicker metal frames.

- For repairing a cracked metal frame, MIG welding would be the most suitable option due to its speed, ease of use, and ability to produce strong welds on thinner metal frames.

4. How would you diagnose and repair an electrical fault in a piece of machinery?

- Inspect the electrical components for any signs of damage or loose connections.

- Use a multimeter to test the voltage and continuity of the electrical circuits.

- Check the fuses and circuit breakers for any blown or tripped devices.

- Inspect the wiring harness for any damaged or broken wires.

- Once the fault has been diagnosed, replace or repair the faulty components and test the system to ensure it is functioning properly.

5. What are the safety precautions you take when working with heavy machinery?

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a hard hat.

- Inspect the machinery before each use to ensure it is in good working condition.

- Never operate machinery that you are not trained or authorized to use.

- Be aware of your surroundings and potential hazards when operating machinery.

- Follow all safety protocols and procedures established by the company.

- Never work alone when operating heavy machinery.

- Report any accidents or near-misses to your supervisor immediately.

6. What is your experience with predictive maintenance and how do you use it to prevent breakdowns?

- Predictive maintenance involves using data and analytics to predict when a machine is likely to fail.

- By monitoring key performance indicators (KPIs) such as vibration, temperature, and power consumption, we can identify potential problems before they occur.

- This allows us to schedule maintenance activities proactively, preventing unplanned breakdowns and reducing downtime.

- I have used predictive maintenance in previous roles to improve equipment reliability and reduce maintenance costs by up to 20%.

7. How do you stay up-to-date with the latest technologies and best practices in the maintenance field?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Take online courses and certifications.

- Network with other maintenance professionals.

- By staying up-to-date with the latest technologies and best practices, I can ensure that I am providing the best possible maintenance services to my clients.

8. What is your experience with managing a team of maintenance technicians?

- In my previous role, I was responsible for managing a team of 10 maintenance technicians.

- My responsibilities included:

- Scheduling and assigning work orders.

- Providing technical support and guidance to my team.

- Evaluating and improving team performance.

- Ensuring compliance with safety and environmental regulations.

- I am confident in my ability to manage a team of maintenance technicians and ensure that all maintenance activities are performed safely, efficiently, and effectively.

9. What is your experience with root cause analysis?

- Root cause analysis is a process of identifying the underlying cause of a problem or failure.

- In my previous role, I used root cause analysis to identify and resolve a number of equipment failures.

- My approach to root cause analysis typically involves:

- Gathering data about the problem or failure.

- Analyzing the data to identify potential causes.

- Testing the potential causes to determine the root cause.

- Developing and implementing corrective actions to prevent the problem or failure from recurring.

- I have found root cause analysis to be a valuable tool for improving equipment reliability and reducing maintenance costs.

10. What are your career goals and how do you see this role fitting into your long-term plans?

- My career goal is to become a maintenance manager.

- I believe that this role will provide me with the opportunity to develop my skills and experience in all aspects of maintenance management.

- I am confident that I can make a significant contribution to your company and help you achieve your maintenance goals.

- In the long term, I hope to use my experience to become a leader in the maintenance field and to make a positive impact on the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Upkeep Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Upkeep Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Upkeep Mechanic is responsible for maintaining and repairing a wide range of equipment and machinery. They perform scheduled preventive maintenance, troubleshoot issues, and make repairs promptly and efficiently to ensure the smooth operation of the workplace.

1. Maintenance

Upkeep Mechanics perform routine maintenance tasks to prevent equipment breakdowns and extend the life of assets. This includes:

- Inspecting equipment for wear and tear

- Lubricating moving parts

- Adjusting and calibrating equipment

- Replacing worn or damaged parts

2. Repairs

When equipment breaks down, Upkeep Mechanics diagnose the problem and make repairs. This may involve:

- Troubleshooting electrical and mechanical issues

- Disassembling and reassembling equipment

- Replacing defective parts

- Testing and calibrating repaired equipment

3. Troubleshooting

Upkeep Mechanics are skilled at troubleshooting problems with equipment. They use their knowledge of mechanical and electrical systems to identify the root cause of a problem and develop a solution.

4. Safety

Upkeep Mechanics must comply with all safety regulations and procedures. This includes:

- Wearing appropriate safety gear

- Using equipment safely

- Following lock-out/tag-out procedures

- Reporting any unsafe conditions

Interview Tips

Preparing for an Upkeep Mechanic interview can help you make a strong impression on the hiring manager. Here are a few tips to help you prepare:

1. Research the Company

Familiarize yourself with the company’s history, mission, and values. This will show the interviewer that you are interested in the company and its culture.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and articulate during the interview.

3. Highlight Your Skills

Be sure to highlight your skills and experience that are relevant to the position. Use examples to demonstrate your abilities.

4. Be Prepared to Talk About Your Safety Experience

Safety is a top priority for Upkeep Mechanics. Be prepared to talk about your safety experience and how you have followed safety procedures in the past.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Upkeep Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.