Feeling lost in a sea of interview questions? Landed that dream interview for Utility Pipe Layer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Utility Pipe Layer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

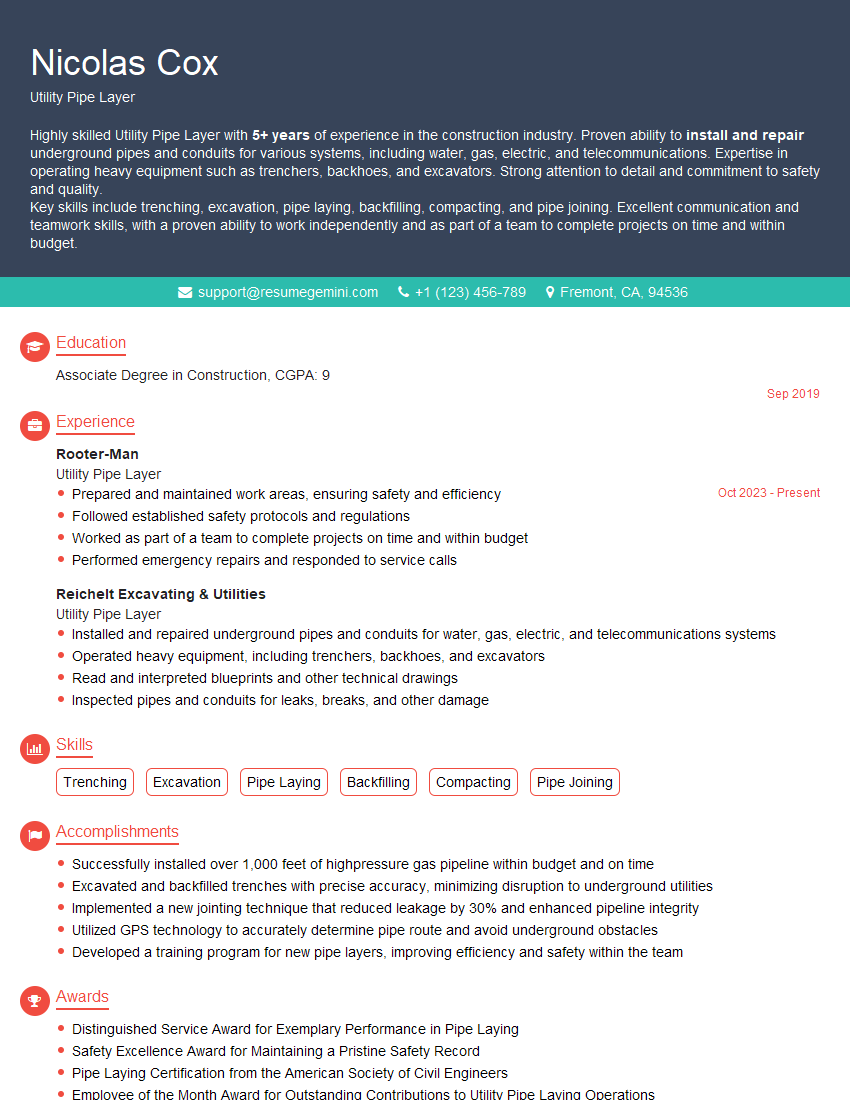

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Utility Pipe Layer

1. What type of materials have you utilized in the past for pipe laying?

In my previous role, I have worked with a variety of pipe materials, including:

- PVC

- HDPE

- Concrete

- Ductile iron

2. Briefly describe the steps involved in laying underground pipe.

Site preparation

- Excavating the trench

- Installing bedding material

Pipe installation

- Lowering the pipe into the trench

- Joining the pipe sections

Backfilling

- Filling the trench with soil or other material

- Compacting the backfill

3. What methods have you used to locate underground utilities before digging?

I have utilized the following methods to locate underground utilities:

- Contacting the local utility companies

- Using a utility locator

- Hand-digging to expose the utilities

4. Can you explain the difference between a sanitary sewer and a storm drain?

- Sanitary sewer: Transports wastewater from homes and businesses to a treatment plant.

- Storm drain: Collects and transports rainwater runoff to a nearby body of water.

5. What safety precautions should be taken when working in a trench?

- Wear proper safety gear, such as a hard hat, gloves, and safety glasses.

- Inspect the trench for hazards before entering.

- Use a trench box or shoring to prevent cave-ins.

- Have a spotter outside the trench to watch for hazards.

6. How do you ensure that the pipe is installed at the correct depth and grade?

- Use a level or transit to measure the depth and grade of the trench.

- Adjust the bedding material as needed to achieve the correct depth and grade.

- Use a string line to guide the installation of the pipe.

7. What types of equipment have you used to install and repair underground pipe?

- Excavators

- Backhoes

- Trenchers

- Pipe fusion machines

- Leak detection equipment

8. What is the importance of proper compaction of the backfill material?

- Prevents settling and subsidence of the ground surface.

- Protects the pipe from damage caused by movement of the soil.

- Ensures the long-term stability of the pipe installation.

9. How do you handle working in confined spaces, such as a trench?

- Wear proper safety gear, such as a respirator and harness.

- Ventilate the space to ensure adequate air flow.

- Have a spotter outside the space to watch for hazards.

- Follow all safety protocols and procedures.

10. What are the environmental regulations that apply to utility pipe laying?

The following environmental regulations apply to utility pipe laying:

- Clean Water Act

- Safe Drinking Water Act

- Endangered Species Act

- National Environmental Policy Act

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Utility Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Utility Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Utility Pipe Layer, also known as a Pipeliner, is a skilled professional responsible for installing, repairing, and maintaining underground utility pipes and pipelines. They work on various types of pipes, including water, gas, sewer, and electrical lines.

1. Installation and Repair

Utility Pipe Layers play a key role in installing new utility pipes and repairing existing ones. Their tasks include:

- Preparing the trench by excavating and grading the ground

- Laying the pipes according to specifications and ensuring proper alignment and depth

- Joining the pipes using various techniques, such as welding, threading, or solvent welding

- Testing the pipes for leaks and ensuring they meet safety standards

- Backfilling the trench and restoring the surface to its original condition

2. Maintenance and Inspection

Utility Pipe Layers also perform maintenance and inspection tasks to ensure the proper functioning and safety of utility pipelines. They:

- Inspect pipelines for leaks, corrosion, or damage using visual checks or specialized equipment

- Repair minor leaks or damage to restore the integrity of the pipeline

- Monitor pressure and flow rates to ensure the pipeline is operating efficiently

- Perform preventative maintenance tasks, such as cleaning and flushing the pipelines to remove debris

3. Safety and Regulations

Utility Pipe Layers are responsible for adhering to strict safety regulations and industry standards. They:

- Follow all safety protocols and wear appropriate protective gear

- Use proper excavation techniques to prevent damage to existing infrastructure

- Ensure that pipes are installed according to local building codes and environmental regulations

- Report any hazardous conditions or potential risks to supervisors

4. Equipment and Tools

Utility Pipe Layers use a variety of equipment and tools to perform their tasks, including:

- Backhoes and excavators for digging trenches

- Pipe benders for adjusting the shape of pipes

- Welding equipment for joining pipes

- Leak detection equipment for identifying leaks

- Pressure gauges and flow meters for monitoring pipeline performance

Interview Tips

Preparing for an interview for a Utility Pipe Layer position requires research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will demonstrate your interest and enthusiasm for the opportunity. Research the company’s history, mission, values, and recent projects. Learn about the specific requirements and responsibilities of the Utility Pipe Layer position, including any specialized skills or certifications needed.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers ahead of time. Practice speaking clearly and concisely, highlighting your relevant skills and experience. Prepare examples of your work experience that showcase your problem-solving abilities, teamwork, and attention to safety. You can also practice answering behavioral interview questions using the STAR method (Situation, Task, Action, Result).

3. Highlight Your Safety Mindset

Safety is paramount in the utility industry. Emphasize your commitment to following safety protocols and adhering to industry standards. Discuss your experience in using personal protective equipment, identifying potential hazards, and reporting safety concerns. Explain how you prioritize safety in all aspects of your work.

4. Demonstrate Your Knowledge of Equipment and Techniques

Utility Pipe Layers use a variety of equipment and techniques to perform their tasks. Show the interviewer that you are familiar with the tools of the trade. Discuss your experience using backhoes, excavators, pipe benders, welding equipment, and leak detection equipment. Explain your understanding of different pipe laying techniques and how you ensure the integrity of the pipelines.

5. Emphasize Your Physical Fitness and Endurance

Utility Pipe Layer jobs can be physically demanding. Highlight your physical fitness and endurance during the interview. Describe your experience working in physically strenuous conditions and your ability to work long hours. Explain how you take care of your physical well-being and maintain your fitness levels.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview, even if the job requires manual labor. Arrive on time to demonstrate your punctuality and respect for the interviewer’s time. Be polite and courteous throughout the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Utility Pipe Layer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!