Feeling lost in a sea of interview questions? Landed that dream interview for Vac Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Vac Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

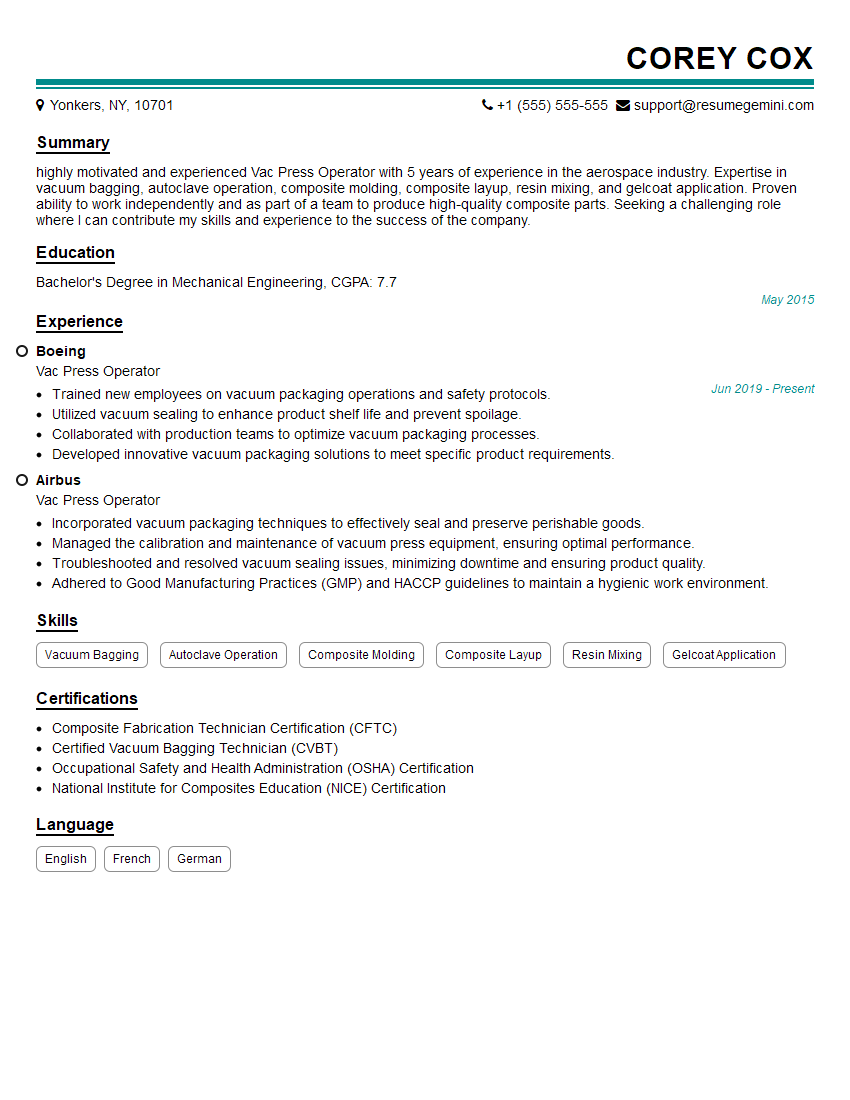

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vac Press Operator

1. Can you talk about the safety precautions you follow while operating the Vac Press?

The safety precautions I follow while operating the Vac Press are as follows:

- I ensure to wear appropriate safety gear, including safety glasses, gloves, and earplugs, while operating the machine.

- I always inspect the machine and work area before each use to ensure that everything is in good working order.

- I keep the work area clean and free of debris to prevent accidents.

- I never operate the machine if I am feeling tired or under the influence of drugs or alcohol.

- I follow all manufacturer instructions and guidelines for operating the Vac Press safely.

2. What are the key steps involved in the Vac Press process?

- Preparing the Materials: This involves selecting and preparing the materials to be bonded together, ensuring they are clean and free of contaminants.

- Applying Vacuum: The materials are then placed in the vacuum chamber, and a vacuum is applied to remove air from between them.

- Heating: Heat is then applied to the materials, causing them to soften and bond together.

- Cooling: Once the materials are bonded, they are cooled to room temperature to complete the process.

3. What are the different types of materials that can be bonded using a Vac Press?

- Wood

- Plastic

- Metal

- Glass

- Fabric

- Foam

4. What are the typical applications of a Vac Press?

- Laminating

- Veneering

- Edge banding

- Thermoforming

- Composite bonding

5. What are some common troubleshooting tips for Vac Press operation?

- Check if the vacuum pump is working properly.

- Inspect the vacuum bag for leaks.

- Ensure that the heating element is reaching the desired temperature.

- Check the bonding time and temperature to ensure they are appropriate for the materials being used.

- Clean the vacuum chamber and platens regularly to prevent contamination.

6. What types of maintenance are required for a Vac Press?

- Regular cleaning of the vacuum chamber and platens

- Inspection and replacement of vacuum bags and hoses

- Calibration of the vacuum pump and heating element

- Lubrication of moving parts

- Electrical safety checks

7. What are the key factors to consider when selecting a Vac Press?

- The size and capacity of the vacuum chamber

- The heating element’s power and temperature range

- The vacuum pump’s capacity and performance

- The availability of features such as automatic timers and temperature controls

- The manufacturer’s reputation and customer support

8. What is the difference between a heated and an unheated Vac Press?

A heated Vac Press has a heating element that allows it to apply heat to the materials being bonded, while an unheated Vac Press does not. Heated Vac Presses are used for applications where heat is required to activate the adhesive or soften the materials being bonded. Unheated Vac Presses are used for applications where heat is not required or could damage the materials.

9. What are some of the advantages of using a Vac Press?

- Improved bond strength and quality

- Reduced production time

- Elimination of air bubbles and voids

- Versatility in bonding a wide range of materials

- Ease of operation

10. What are some of the challenges of using a Vac Press?

- The initial investment cost can be high.

- The machine requires regular maintenance and calibration.

- Improper use can lead to safety hazards.

- The process can be time-consuming, especially for large or complex projects.

- The machine requires a dedicated workspace with proper ventilation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vac Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vac Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Vac Press Operator, you will have the following key responsibilities:

1. Operate and maintain vacuum press equipment

This includes setting up, operating, and troubleshooting vacuum presses to ensure they are working properly.

- Setting up and calibrating vacuum press equipment according to specifications

- Operating vacuum press equipment to laminate, bond, or seal materials

- Troubleshooting and repairing vacuum press equipment as needed

2. Prepare materials for vacuum pressing

This includes cutting, trimming, and cleaning materials to prepare them for vacuum pressing.

- Cutting and trimming materials to the correct size and shape

- Cleaning materials to remove dirt, dust, and other contaminants

- Applying adhesives or other materials to materials as needed

3. Monitor vacuum pressing process

This includes monitoring the vacuum pressure, temperature, and other factors to ensure the process is running smoothly.

- Monitoring vacuum pressure, temperature, and other factors during the vacuum pressing process

- Making adjustments to the process as needed to ensure the materials are properly laminated, bonded, or sealed

- Ensuring that the materials are cured properly after the vacuum pressing process is complete

4. Inspect finished products

This includes inspecting finished products to ensure they meet quality standards.

- Inspecting finished products for defects such as bubbles, wrinkles, or tears

- Rejecting products that do not meet quality standards

- Working with other departments to resolve quality issues

Interview Tips

Here are some tips to help you ace your interview for a Vac Press Operator position:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position.

- Visit the company’s website and social media pages

- Read about the company in industry publications

- Talk to people who work for the company, if possible

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with vacuum press equipment?

- How do you handle quality control issues?

3. Prepare questions to ask the interviewer

This shows that you are interested in the position and the company.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

- What is the company’s policy on training and development?

- What is the company’s safety record?

4. Dress professionally and arrive on time for your interview

This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

- Dress in business attire

- Be on time for your interview

- Bring a portfolio of your work, if you have one

- Be prepared to answer questions about your experience and qualifications

Next Step:

Now that you’re armed with the knowledge of Vac Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Vac Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini