Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Vacuum Bottle Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Vacuum Bottle Assembler so you can tailor your answers to impress potential employers.

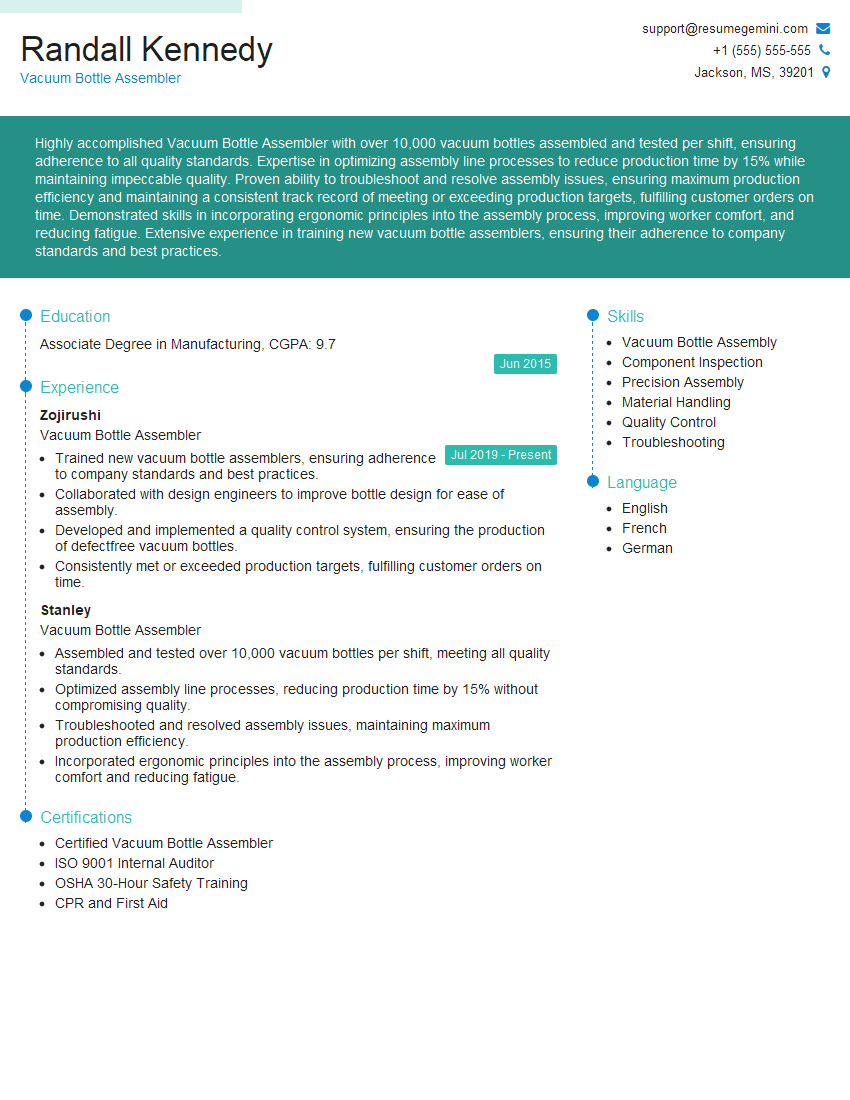

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Bottle Assembler

1. Describe the key components of a Vacuum Bottle and their functions?

Vacuum Bottle consists of following key components:

- Insulated Body: The outer body of the vacuum bottle is made of durable material such as stainless steel or plastic. It provides structural support, protection, and insulation.

- Glass or Stainless Steel Vacuum Flask: The inner flask is made of glass or stainless steel. It has a double wall with a vacuum between the walls, creating a highly insulated space that minimizes heat transfer.

- Sealing Gasket: A rubber or silicone gasket is placed between the inner and outer body to create an airtight seal, preventing air from entering the vacuum space.

- Stopper or Cap: The stopper or cap fits on the top of the bottle to seal it and allow for liquid dispensing. It may have a pouring spout or a drinking hole.

- Carrying Strap or Handle: Some vacuum bottles have a carrying strap or handle for easy portability.

2. What are the different materials used to manufacture Vacuum Bottles?

- Stainless Steel: Durable, corrosion-resistant, easy to clean, and maintains temperature well.

- Plastic: Lightweight, less expensive, but may not be as durable or insulating as stainless steel.

- Glass: Provides excellent insulation but can be fragile and susceptible to breakage.

- Ceramic: Non-porous, durable, and good at retaining heat, but can be heavy.

- Bamboo: Sustainable and biodegradable, provides some insulation but may not be as durable as other materials.

3. Explain the process of assembling a Vacuum Bottle?

- Prepare components: Gather all necessary components, including the insulated body, inner flask, sealing gasket, stopper, and any additional parts (e.g., carrying strap).

- Insert inner flask: Place the inner flask into the insulated body.

- Install sealing gasket: Position the sealing gasket around the inner flask to create an airtight seal.

- Attach stopper: Fit the stopper or cap onto the bottle, ensuring a tight fit.

- Assemble additional parts: Attach any additional parts, such as a carrying strap or handle.

- Quality check: Inspect the assembled bottle for any defects or leaks.

4. How do you ensure the quality of Vacuum Bottles during assembly?

- Material inspection: Examine incoming materials for defects or damage.

- Visual inspection: Check for any scratches, dents, or other imperfections during assembly.

- Leak testing: Conduct a leak test to ensure the vacuum seal is airtight.

- Insulation testing: Test the bottle’s insulation capabilities to meet performance standards.

- Durability testing: Perform durability tests to ensure the bottle can withstand normal use and handling.

- Compliance testing: Ensure that the assembled bottles meet industry standards and regulatory requirements.

5. Describe the potential hazards and safety precautions involved in Vacuum Bottle assembly?

Hazards

- Sharp edges or broken glass from damaged components.

- Fumes and vapors from adhesives or cleaning solutions.

- Ergonomic risks from repetitive movements.

Precautions

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Handle components carefully to avoid cuts or injuries.

- Use proper ventilation to minimize exposure to fumes and vapors.

- Maintain good posture and take breaks to reduce ergonomic risks.

- Follow established safety protocols and report any hazards or incidents promptly.

6. How do you troubleshoot common Vacuum Bottle assembly defects?

- Leaks: Inspect the sealing gasket for damage or improper installation. Tighten the stopper or cap securely.

- Poor insulation: Ensure that the inner flask is properly seated and the vacuum seal is intact.

- Broken components: Replace any damaged or broken components, such as the inner flask or stopper.

- Assembly issues: Check for any misalignments or loose connections during assembly. Reassemble the bottle carefully.

- Material defects: Contact the supplier or manufacturer if any material defects are discovered.

7. What techniques do you use to increase Vacuum Bottle assembly efficiency?

- Streamline assembly process: Analyze and optimize the assembly steps to eliminate unnecessary movements or delays.

- Use jigs and fixtures: Utilize jigs and fixtures to hold components in place and guide assembly, ensuring accuracy and efficiency.

- Train and empower assemblers: Provide proper training and empower assemblers to identify and resolve potential issues quickly.

- Automate tasks: Implement automated processes for repetitive tasks, such as leak testing or quality inspection, to improve consistency and speed.

- Ergonomic workstation design: Design workstations to minimize fatigue and maximize productivity.

8. What are the latest advancements in Vacuum Bottle technology that you are aware of?

- Self-cleaning bottles: Bottles with built-in UV or antibacterial technology to eliminate germs and odors.

- Smart temperature control: Bottles that can maintain a desired temperature for hours using built-in sensors and heating elements.

- Improved insulation materials: New materials and techniques to enhance vacuum insulation and temperature retention.

- Sustainable materials: Bottles made from eco-friendly materials, such as biodegradable plastics or recycled metals.

- Innovative designs: Unique shapes, colors, and textures to enhance usability and appeal.

9. How do you stay up-to-date with the latest Vacuum Bottle assembly techniques?

- Attend industry events and conferences: Participate in trade shows, workshops, and seminars to learn about new technologies and best practices.

- Read technical journals and articles: Subscribe to industry publications and research papers to stay informed about advancements in the field.

- Network with colleagues and suppliers: Engage with other professionals in the industry to exchange knowledge and learn about innovations.

- Online courses and certifications: Enroll in online courses or certification programs to enhance skills and stay abreast of industry trends.

- Seek feedback and continuous improvement: Regularly evaluate assembly processes and seek feedback from colleagues to identify areas for improvement.

10. What motivated you to pursue a career as a Vacuum Bottle Assembler?

- Interest in precision manufacturing: Fascinated by the intricate process of assembling complex products.

- Attention to detail: Ability to focus on small details and ensure high-quality workmanship.

- Desire to contribute to a meaningful product: Appreciation for the role vacuum bottles play in keeping beverages hot or cold for extended periods.

- Opportunities for growth and advancement: Excited by the potential to learn new skills and progress within the industry.

- Team environment: Enjoy working collaboratively with others to achieve a common goal.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Bottle Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Bottle Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vacuum Bottle Assemblers are responsible for assembling and testing vacuum bottles. They must have a strong understanding of the assembly process and be able to work quickly and accurately. Key responsibilities include:

1. Assemble vacuum bottles

Vacuum Bottle Assemblers must be able to assemble vacuum bottles quickly and accurately. They must follow the assembly instructions carefully and ensure that all parts are properly installed. They must also check for defects and ensure that the finished product meets all quality standards.

2. Test vacuum bottles

Vacuum Bottle Assemblers must also be able to test vacuum bottles for leaks and other defects. They must use specialized equipment to test the bottles and ensure that they meet all safety and performance standards.

3. Maintain work area

Vacuum Bottle Assemblers must also be able to maintain their work area clean and organized. They must follow all safety regulations and keep their equipment in good working order.

4. Keep up-to-date on new products and technologies

Vacuum Bottle Assemblers must also be able to keep up-to-date on new products and technologies. They must be able to learn new skills and adapt to new processes as needed.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips to help you ace your interview for a Vacuum Bottle Assembler position:

1. Research the company

Before your interview, take some time to research the company. This will help you learn more about their products, their culture, and their values. You can find this information on the company website, in industry publications, and on social media.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

4. Be on time

Punctuality is important, so make sure that you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vacuum Bottle Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.