Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Vacuum Conditioner Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

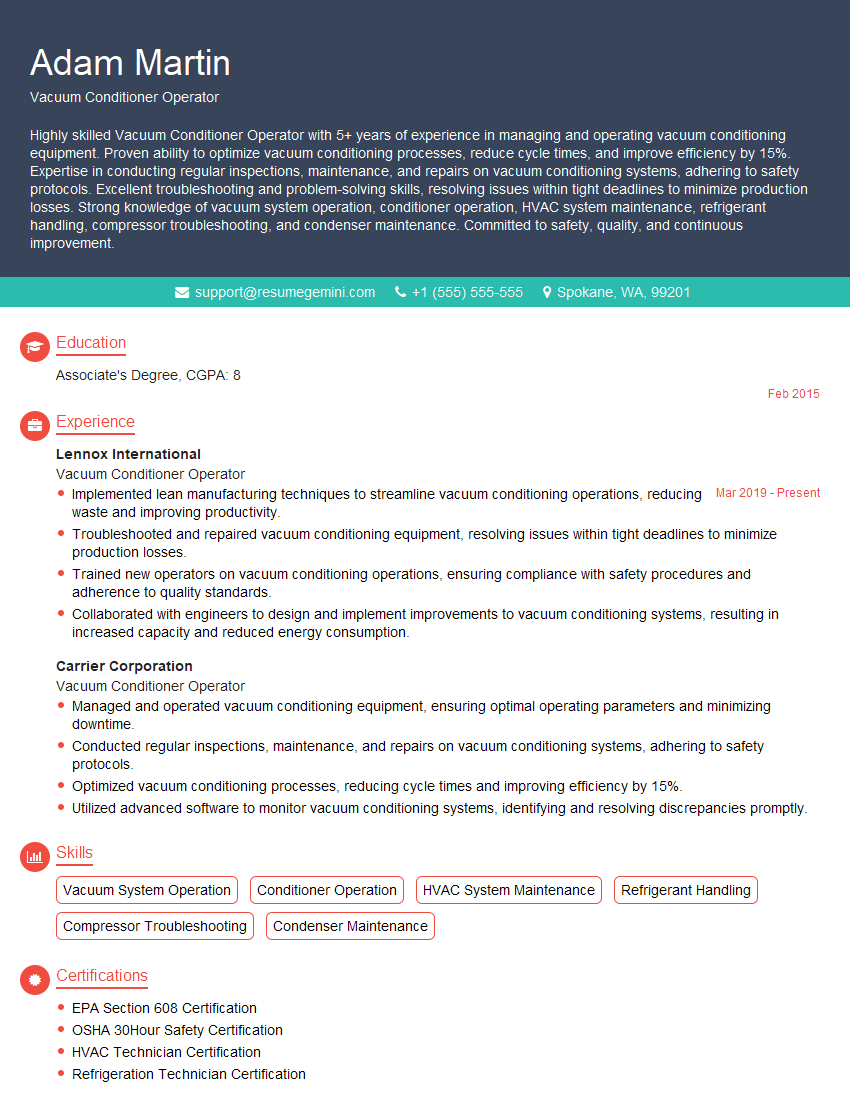

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Conditioner Operator

1. What are the main responsibilities of a Vacuum Conditioner Operator?

The primary responsibilities of a Vacuum Conditioner Operator include:

- Operating and monitoring vacuum conditioning equipment to remove moisture, contaminants, and gases from electronic components.

- Adhering to established procedures and specifications for vacuum conditioning processes.

- Performing quality checks on conditioned components to ensure they meet the required standards.

- Maintaining a clean and organized work area, including equipment calibration and record-keeping.

2. Describe the different types of vacuum conditioning processes and their applications.

Vacuum Baking

- Purpose: Removes moisture and solvents from components.

- Applications: Electronic assemblies, medical devices, and aerospace components.

Vacuum Degassing

- Purpose: Removes trapped gases from materials.

- Applications: Metals, plastics, and composites.

Vacuum Impregnation

- Purpose: Fills pores and voids with a sealant or adhesive.

- Applications: Castings, porous materials, and electronic components.

3. What are the key parameters to monitor during vacuum conditioning?

The key parameters to monitor during vacuum conditioning include:

- Vacuum level and pressure.

- Temperature of the components and equipment.

- Time and duration of the conditioning process.

- Component appearance and quality.

4. How do you troubleshoot common vacuum conditioning problems?

Common vacuum conditioning problems include:

- Leaks: Check for leaks in the vacuum chamber, hoses, and fittings.

- Contamination: Inspect the components and equipment for any foreign materials.

- Pressure fluctuations: Check the vacuum pump and valves for proper operation.

- Temperature variations: Ensure that the temperature control system is functioning properly.

5. What safety precautions should be taken when working with vacuum conditioning equipment?

Safety precautions for working with vacuum conditioning equipment include:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Ensure that the equipment is properly grounded and electrically safe.

- Operate the equipment in a well-ventilated area.

- Follow all established safety protocols and procedures.

6. How do you ensure the quality of vacuum conditioned components?

To ensure the quality of vacuum conditioned components:

- Follow standardized procedures and specifications.

- Use calibrated instruments and equipment.

- Perform thorough visual inspections and quality checks.

- Document the conditioning process and results.

7. What is your experience with vacuum conditioning equipment and processes?

I have extensive experience with vacuum conditioning equipment and processes. In my previous role, I was responsible for operating and maintaining a variety of vacuum conditioning systems. I have experience with vacuum baking, vacuum degassing, and vacuum impregnation techniques. I am also familiar with the quality control and safety protocols associated with vacuum conditioning.

8. Are there any recent advancements in vacuum conditioning technology that you are aware of?

Yes, there are several recent advancements in vacuum conditioning technology that I am aware of:

- Vacuum microwave conditioning: This technique combines vacuum conditioning with microwave heating to enhance moisture removal.

- Pulsed vacuum conditioning: This technique involves alternating between vacuum and atmospheric pressure to improve degassing.

- Ultra-high vacuum conditioning: This technique uses extremely low pressures to achieve deeper conditioning and remove trace contaminants.

9. How do you stay up-to-date with the latest developments in the field?

I stay up-to-date with the latest developments in the field by:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with other professionals in the field.

- Participating in online forums and discussion groups.

10. Do you have any questions for me?

I am interested in learning more about the vacuum conditioning equipment and processes used in your company. Can you provide me with some additional details?

I am also curious about the company’s commitment to quality and safety. Can you share some examples of how these values are reflected in your daily operations?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Conditioner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Conditioner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Vacuum Conditioner Operator is responsible for operating and maintaining vacuum conditioning equipment to ensure the proper conditioning of textiles. This involves monitoring the equipment, making adjustments as needed, and troubleshooting any problems that may arise.

1. Operate Vacuum Conditioning Equipment

The Vacuum Conditioner Operator operates and monitors vacuum conditioning equipment to ensure that textiles are properly conditioned. This includes loading and unloading textiles, setting the appropriate temperature and humidity levels, and monitoring the equipment to ensure that it is functioning properly.

- Load and unload textiles from the vacuum conditioning equipment.

- Set the appropriate temperature and humidity levels for the textiles.

- Monitor the equipment to ensure that it is functioning properly.

- Make adjustments to the equipment as needed to ensure that the textiles are properly conditioned.

2. Maintain Vacuum Conditioning Equipment

The Vacuum Conditioner Operator is responsible for maintaining the vacuum conditioning equipment to ensure that it is in good working order. This includes cleaning the equipment, lubricating the moving parts, and making minor repairs.

- Clean the vacuum conditioning equipment.

- Lubricate the moving parts of the equipment.

- Make minor repairs to the equipment.

- Inspect the equipment regularly to identify any potential problems.

3. Troubleshoot Vacuum Conditioning Equipment

The Vacuum Conditioner Operator is responsible for troubleshooting any problems that may arise with the vacuum conditioning equipment. This includes identifying the problem, determining the cause of the problem, and taking steps to resolve the problem.

- Identify the problem with the vacuum conditioning equipment.

- Determine the cause of the problem.

- Take steps to resolve the problem.

- Document the problem and the steps taken to resolve it.

4. Other Responsibilities

In addition to the above responsibilities, the Vacuum Conditioner Operator may also be responsible for:

- Training new employees on the operation and maintenance of vacuum conditioning equipment.

- Assisting with the development and implementation of new vacuum conditioning processes.

- Working with other departments to ensure that textiles are properly conditioned and handled.

Interview Tips

Preparing for an interview for a Vacuum Conditioner Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to better understand the responsibilities of the position and how your skills and experience align with the company’s needs.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to understand the responsibilities of the position.

- Talk to people in your network who work for the company or who have knowledge of the industry.

2. Practice Answering Interview Questions

One of the best ways to prepare for your interview is to practice answering common interview questions. This will help you to feel more confident and prepared during your interview. There are a number of resources available online and in libraries that can help you to practice answering interview questions.

- Prepare a list of common interview questions and practice answering them out loud.

- Ask a friend or family member to help you practice answering interview questions.

- Use online resources or books to help you prepare for your interview.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Choose a suit or business casual attire that is appropriate for the company culture.

- Make sure that your clothes are clean and pressed.

- Accessorize with a tie, scarf, or other professional accessories.

4. Be on Time

Punctuality is important, so make sure that you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Plan your route to the interview in advance.

- Give yourself plenty of time to get to the interview location.

- If you are running late, call the interviewer to let them know.

Next Step:

Now that you’re armed with the knowledge of Vacuum Conditioner Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Vacuum Conditioner Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini