Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Vacuum Form Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Vacuum Form Operator so you can tailor your answers to impress potential employers.

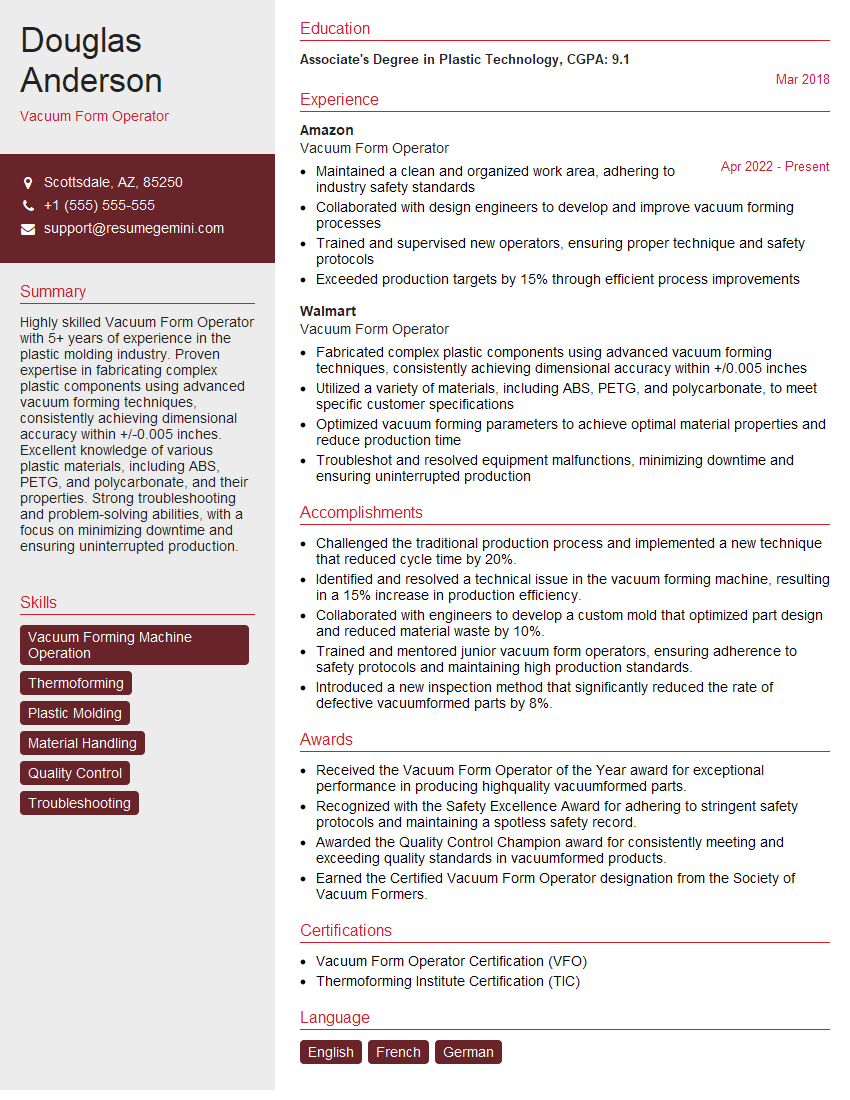

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Form Operator

1. What is vacuum forming, and how does it differ from other plastic forming processes?

- Vacuum forming is a plastic forming process in which a heated plastic sheet is stretched over a mold and then vacuum-sealed to create a three-dimensional object.

- It differs from other plastic forming processes such as injection molding and blow molding in that it uses a single sheet of plastic and does not require the use of a mold.

2. What are the different types of vacuum forming machines?

- There are two main types of vacuum forming machines: mechanical and hydraulic.

- Mechanical vacuum forming machines use a mechanical force to create the vacuum, while hydraulic vacuum forming machines use a hydraulic force.

- Mechanical vacuum forming machines are typically smaller and less expensive than hydraulic vacuum forming machines, but they are also less powerful.

- Hydraulic vacuum forming machines are more powerful than mechanical vacuum forming machines, but they are also larger and more expensive.

3. What are the factors that affect the quality of a vacuum-formed product?

- The quality of a vacuum-formed product is affected by several factors, including the quality of the plastic sheet, the temperature of the plastic sheet, the vacuum pressure, and the mold design.

- If any of these factors are not controlled properly, it can result in defects in the vacuum-formed product.

4. What are the common problems that can occur during vacuum forming?

- The most common problems that can occur during vacuum forming include: wrinkles, bubbles, and sink marks.

- Wrinkles occur when the plastic sheet is not stretched properly over the mold.

- Bubbles occur when air becomes trapped between the plastic sheet and the mold.

- Sink marks occur when the plastic sheet does not cool evenly, causing it to sag.

5. How can you troubleshoot problems that occur during vacuum forming?

- To troubleshoot problems that occur during vacuum forming, you need to first identify the cause of the problem.

- Once you have identified the cause of the problem, you can then take steps to correct it.

- For example, if wrinkles are occurring, you can try increasing the temperature of the plastic sheet or decreasing the vacuum pressure.

6. What are the safety precautions that should be taken when operating a vacuum forming machine?

- When operating a vacuum forming machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions for safe operation.

7. What are the different types of plastic materials that can be used for vacuum forming?

- A variety of plastic materials can be used for vacuum forming, including: polystyrene, polyethylene, polypropylene, and ABS.

- Each type of plastic material has its own unique properties that make it suitable for different applications.

- For example, polystyrene is a lightweight and inexpensive material that is often used for disposable products, while polyethylene is a strong and durable material that is often used for industrial applications.

8. What are the applications of vacuum forming?

- Vacuum forming is used in a wide variety of applications, including:

- Automotive parts

- Appliances

- Toys

- Packaging

- Medical devices

9. What are the advantages of vacuum forming over other plastic forming processes?

- Vacuum forming has several advantages over other plastic forming processes, including:

- It is a relatively simple and inexpensive process.

- It can be used to produce a wide variety of products.

- It is a versatile process that can be used to create both simple and complex shapes.

10. What are the disadvantages of vacuum forming?

- Vacuum forming also has some disadvantages, including:

- It can be difficult to control the thickness of the formed product.

- The formed product can have a rough surface finish.

- Vacuum forming is not suitable for producing high-volume products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Form Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Form Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vacuum Form Operators play a crucial role in the production process of plastic products using vacuum forming techniques. Their primary responsibilities include:

1. Equipment Operation

Operate and maintain vacuum forming machines to mold plastic sheets into desired shapes.

- Set up and adjust machine parameters, such as heat and pressure, to ensure proper molding.

- Monitor machine performance, troubleshoot any issues, and perform routine maintenance.

2. Material Handling

Handle plastic sheets and other materials safely and efficiently.

- Load and unload plastic sheets into the forming machine.

- Inspect materials for defects and ensure proper storage.

3. Quality Control

Inspect finished products for quality and accuracy.

- Compare finished products to specifications and identify any deviations.

- Maintain records of quality checks and report any non-conformances.

4. Production Support

Assist with production processes and maintain a clean and organized work area.

- Clean and maintain vacuum forming equipment and surrounding areas.

- Assist with material handling and other tasks as needed.

Interview Tips

To ace your Vacuum Form Operator interview, consider the following preparation tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and the specific role you are applying for.

- Visit the company website and social media pages to gather information about their products, services, and culture.

- Read online reviews and articles to gain insights into the company’s reputation and industry standing.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions related to your skills, experience, and the role’s requirements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Quantify your results whenever possible to demonstrate the impact of your work.

3. Highlight Your Experience and Skills

Tailor your resume and interview answers to emphasize your relevant experience and skills for the Vacuum Form Operator role.

- Showcase your knowledge of vacuum forming techniques, equipment operation, and quality control procedures.

- Highlight your attention to detail, precision, and ability to work independently.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest in the role and the company.

- Inquire about the company’s production processes, growth plans, or any specific challenges related to the position.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vacuum Form Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!