Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Vacuum Furnace Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Vacuum Furnace Operator so you can tailor your answers to impress potential employers.

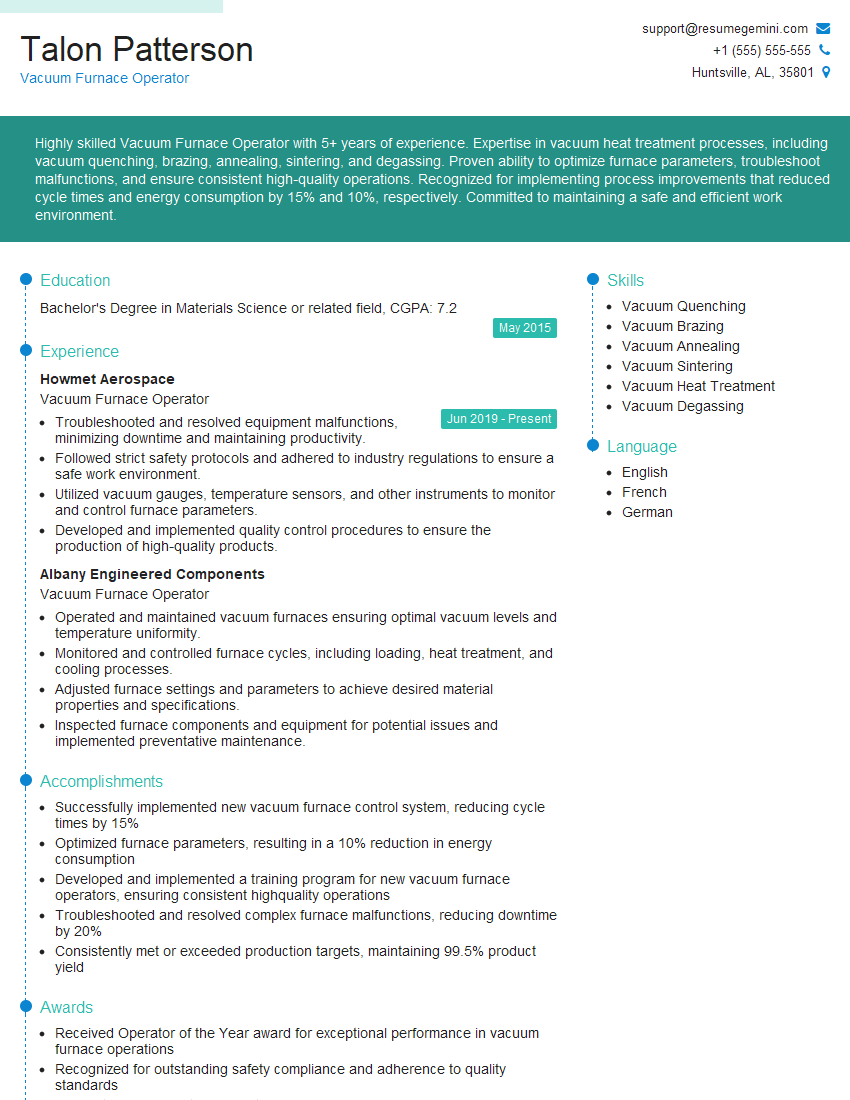

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Furnace Operator

1. Explain the purpose and function of a vacuum furnace?

A vacuum furnace is a specialized heating equipment used to heat treat materials in a vacuum environment. It creates a vacuum chamber with extremely low pressure, typically in the range of 10^-3 to 10^-9 torr, by evacuating the air from the chamber.

- The primary purpose of a vacuum furnace is to eliminate the presence of oxygen and other gases during the heat treatment process.

- This controlled environment prevents oxidation, decarburization, and other adverse reactions that can compromise the quality and properties of the treated materials.

2. Describe the different types of vacuum furnaces based on their heating methods?

Electrically heated vacuum furnaces

- Heat is generated by electrical resistance elements or induction coils, providing precise temperature control and uniform heating.

- Examples include resistance-heated box furnaces, induction-heated furnaces, and electron beam furnaces.

Gas-fired vacuum furnaces

- Heat is generated by gas burners, allowing for high temperatures and rapid heating rates.

- They are commonly used for large-scale heat treatment applications, such as annealing and tempering of heavy metal components.

3. What are the key parameters that need to be monitored and controlled during vacuum heat treatment?

- Temperature: Closely controlled temperature profiles ensure consistent and desired material properties.

- Vacuum level: Maintaining a high vacuum level minimizes the presence of oxygen and impurities.

- Heating and cooling rates: Controlled heating and cooling rates prevent thermal stress and defects in the material.

- Gas flow: In some cases, controlled gas flow may be introduced to create a specific atmosphere or enhance certain properties.

- Pressure: Monitoring and controlling the pressure inside the vacuum chamber is crucial for maintaining the desired vacuum level.

4. Explain the safety protocols and precautions that must be followed when operating a vacuum furnace?

- Proper training and certification: Operators must be trained and certified to handle vacuum furnaces safely.

- Protective gear: Personal protective equipment such as gloves, safety glasses, and fire-resistant clothing must be worn.

- Chamber integrity: The vacuum chamber must be regularly inspected for leaks or damage to ensure safety.

- Gas hazards: Potential hazards associated with process gases must be understood and appropriate safety measures taken.

- Emergency procedures: Clear emergency protocols must be established and practiced to respond to potential incidents.

5. Describe the different materials that can be heat treated in a vacuum furnace and the specific applications for each?

- Metals: Vacuum heat treatment is commonly used for ferrous metals (steel, cast iron) and non-ferrous metals (aluminum, titanium, copper) for applications in aerospace, automotive, and medical industries.

- Ceramics: Vacuum furnaces provide a controlled environment for sintering, brazing, and annealing of ceramic materials used in electronics, medical devices, and high-temperature applications.

- Composites: Vacuum heat treatment can enhance the strength, stiffness, and durability of composite materials used in aerospace, automotive, and sporting goods.

6. Explain the importance of vacuum heat treatment for specific applications, such as preventing oxidation or improving material properties?

- Oxidation prevention: Vacuum heat treatment eliminates oxygen from the process, preventing oxidation and preserving the surface integrity of the material.

- Material properties enhancement: Vacuum heat treatment can improve material properties such as hardness, strength, toughness, and wear resistance by controlling the microstructure and reducing defects.

7. Describe the maintenance and troubleshooting procedures for a vacuum furnace?

- Regular inspections: Vacuum furnaces require regular inspections for leaks, electrical connections, and mechanical components.

- Vacuum pump maintenance: Vacuum pumps must be regularly serviced to ensure optimal performance and vacuum level.

- Temperature sensor calibration: Temperature sensors need to be calibrated periodically to ensure accurate temperature readings.

- Troubleshooting: Common troubleshooting procedures include addressing vacuum leaks, temperature control issues, and electrical faults.

8. Discuss the environmental and safety considerations associated with vacuum furnace operations?

- Waste management: Proper handling and disposal of hazardous waste generated during vacuum heat treatment, such as spent process gases and contaminated materials.

- Energy efficiency: Optimizing vacuum furnace operations to reduce energy consumption and minimize environmental impact.

- Noise control: Vacuum furnaces may generate noise, so soundproofing or noise-reducing measures may be necessary.

9. Explain the role of vacuum furnace operators in quality control and ensuring product consistency?

- Monitoring and recording process parameters: Operators are responsible for monitoring and recording critical process parameters, such as temperature, vacuum level, and heating/cooling rates.

- Material handling: Proper handling of materials during loading, unloading, and heat treatment is essential to prevent contamination or damage.

- Data analysis: Operators may analyze process data to identify trends, optimize parameters, and ensure product consistency.

10. Describe the career advancement opportunities available for vacuum furnace operators?

- Supervisor: With experience and knowledge, operators can advance to supervisory roles, overseeing vacuum furnace operations and teams.

- Process engineer: Operators with a strong technical background can pursue process engineering roles, focusing on optimizing vacuum heat treatment processes and developing new applications.

- Quality control manager: Operators with a focus on quality control can advance to quality control management positions, ensuring product consistency and compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vacuum Furnace Operators are responsible for the safe and efficient operation of vacuum furnaces, which are used to heat treat metal components in a vacuum environment. Their primary duties include:

1. Furnace Operation

– Load and unload metal components into the furnace

– Monitor and control furnace temperature, pressure, and other process parameters

– Maintain and troubleshoot furnace equipment

2. Quality Control

– Inspect components before and after heat treatment

– Ensure that components meet the required specifications

– Keep records of heat treatment parameters and component inspections

3. Maintenance and Repair

– Perform basic maintenance and repairs on furnace equipment

– Identify and report any malfunctions or safety concerns

– Follow established maintenance and safety procedures

4. Safety and Compliance

– Adhere to all safety regulations and procedures

– Wear appropriate personal protective equipment

– Maintain a clean and organized work area

Interview Tips

Preparing for an interview for a Vacuum Furnace Operator position requires a combination of technical knowledge, research, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

– Visit the company’s website and review their services and industry.

– Read the job description carefully and identify the key responsibilities and requirements.

2. Highlight Relevant Experience and Skills

– Emphasize your experience operating and maintaining vacuum furnaces.

– Showcase your understanding of heat treatment processes and quality control procedures.

3. Prepare Technical Questions

– Anticipate questions about the types of vacuum furnaces you have worked with.

– Be ready to discuss common troubleshooting techniques and safety protocols.

4. Demonstrate Safety Awareness

– Explain your knowledge of and commitment to safety procedures.

– Highlight your experience using personal protective equipment and maintaining a clean work environment.

5. Ask Thoughtful Questions

– Prepare questions to ask the interviewer about the company’s processes, equipment, and safety policies.

– This shows your interest in the position and your commitment to continuous learning.

6. Practice Your Answers

– Rehearse your answers to common interview questions.

– Seek feedback from a mentor or career counselor to refine your responses and improve your confidence.

7. Be Professional and Enthusiastic

– Dress appropriately and arrive on time for your interview.

– Maintain eye contact, speak clearly, and demonstrate a positive attitude.

Next Step:

Now that you’re armed with the knowledge of Vacuum Furnace Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Vacuum Furnace Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini