Are you gearing up for a career in Vacuum Metalizer Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vacuum Metalizer Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

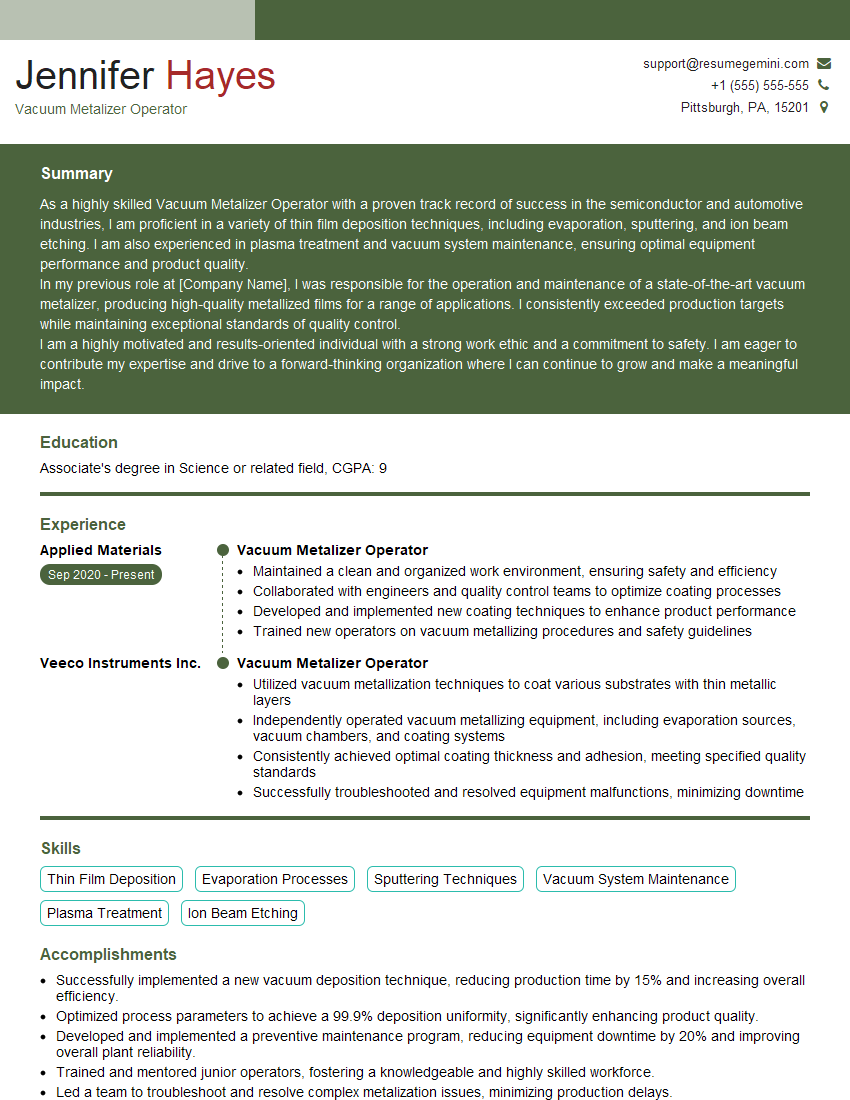

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Metalizer Operator

1. How do you ensure that the vacuum metalizer is operating at optimal conditions?

- Monitoring vacuum levels and adjusting the vacuum pump to maintain the desired pressure.

- Calibrating the temperature controllers to ensure accurate temperature control.

- Inspecting and cleaning the vacuum chamber, electrodes, and substrate holders to maintain a clean and functional environment.

- Monitoring the coating thickness and adhesion using appropriate testing methods.

- Maintaining proper ventilation and exhaust systems to ensure a safe working environment.

2. Describe the process of loading and unloading substrates onto the vacuum metalizer.

- Preparing the substrates by cleaning, degreasing, and etching (if necessary).

- Loading the substrates onto the substrate holders and securing them properly.

- Positioning the substrate holders inside the vacuum chamber and securing them.

- Unloading the substrate holders after the metallization process is complete.

- Inspecting the substrates for any defects or contamination.

3. How do you troubleshoot common issues that may arise during the vacuum metallization process?

- Identifying the problem by observing the symptoms and using diagnostic tools.

- Checking the vacuum system for leaks or blockages.

- Inspecting the electrodes for damage or contamination.

- Adjusting the process parameters, such as temperature, pressure, or deposition rate.

- Consulting with a supervisor or engineer for assistance if needed.

4. Explain the safety precautions that must be taken when operating a vacuum metalizer.

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensuring that the vacuum chamber and electrical connections are properly grounded.

- Following proper lockout/tagout procedures before performing any maintenance or repairs.

- Being aware of the potential for electrical hazards and taking steps to mitigate them.

- Handling hazardous materials, such as chemicals or solvents, according to safety protocols.

5. How do you maintain the vacuum metalizer to ensure its longevity and optimal performance?

- Regularly cleaning and inspecting the vacuum chamber, electrodes, and substrate holders to remove any contamination.

- Calibrating the temperature controllers and vacuum gauges to ensure accurate readings.

- Performing preventive maintenance tasks, such as replacing O-rings and gaskets.

- Monitoring the vacuum pump oil level and changing it as per the manufacturer’s recommendations.

- Keeping a maintenance log to track inspections, repairs, and replacements.

6. How do you calculate the deposition rate for a given metallization process?

- Measuring the thickness of the deposited metal using a thickness gauge.

- Dividing the thickness by the deposition time to calculate the deposition rate in units of thickness per unit time (e.g., angstroms per second).

- Considering the factors that can affect the deposition rate, such as the metal being deposited, the substrate material, and the process parameters.

7. Explain the different types of metallization processes and their applications.

- Physical vapor deposition (PVD): Evaporation, sputtering, ion plating. Used for decorative, functional, and protective coatings.

- Chemical vapor deposition (CVD): Decomposition of gases to form a solid coating. Used for high-temperature coatings and semiconductor applications.

- Electroplating: Deposition of metal from an electrolytic solution. Used for conductive, decorative, and corrosion-resistant coatings.

8. How do you handle and store hazardous materials, such as chemicals and solvents, used in the vacuum metallization process?

- Properly labeling and storing hazardous materials in designated areas.

- Using appropriate PPE when handling hazardous materials.

- Following safety protocols for mixing and using chemicals.

- Disposing of hazardous waste according to environmental regulations.

9. Describe the quality control procedures you follow to ensure the quality of the vacuum metallized products.

- Inspecting the substrates before and after metallization for defects.

- Monitoring the coating thickness and adhesion to meet specifications.

- Performing regular calibration of measuring and testing equipment.

- Maintaining quality control records to track and document the quality of the products.

10. How do you work effectively as part of a team in a vacuum metallization environment?

- Communicating effectively with team members and supervisors.

- Sharing knowledge and expertise with colleagues.

- Collaborating on problem-solving and continuous improvement initiatives.

- Supporting team members in their responsibilities.

- Maintaining a positive and cooperative work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Metalizer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Metalizer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vacuum Metalizer Operator is responsible for operating and maintaining vacuum metalizing equipment in a variety of industries, such as automotive, aerospace, and consumer products. Key responsibilities include:

1. Operating Vacuum Metalizing Equipment

This involves loading and unloading parts, setting up and adjusting equipment, and monitoring the metalizing process.

- Loading and unloading parts into the vacuum chamber

- Setting up and adjusting equipment parameters, such as temperature, pressure, and deposition rate

- Monitoring the metalizing process to ensure that it is proceeding correctly

2. Maintaining Vacuum Metalizing Equipment

This involves cleaning, inspecting, and repairing equipment as needed.

- Cleaning the vacuum chamber and other equipment components

- Inspecting equipment for wear and tear

- Repairing or replacing equipment components as needed

3. Quality Control

This involves inspecting parts for defects and ensuring that they meet quality standards.

- Inspecting parts for defects, such as scratches, dents, or discoloration

- Measuring the thickness and adhesion of the metalized coating

- Ensuring that parts meet quality standards

4. Safety

This involves following all safety procedures and wearing appropriate safety gear.

- Following all safety procedures

- Wearing appropriate safety gear, such as gloves, goggles, and a lab coat

- Maintaining a clean and organized work area

Interview Tips

To ace an interview for a Vacuum Metalizer Operator position, it is important to be well-prepared and to demonstrate your knowledge and skills. Here are some tips:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get an idea of the company culture and work environment.

- Review the job description carefully to identify the key skills and experience required for the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- For the question “Tell me about yourself,” focus on highlighting your skills and experience that are most relevant to the position.

- For the question “Why are you interested in this position,” explain how your skills and experience align with the requirements of the job and how you can contribute to the company.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s growth plans and future goals.

- Ask about the specific challenges and opportunities associated with the position.

- Ask about the company’s training and development programs.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

- Dress in business attire, such as a suit or dress pants and a button-down shirt.

- Arrive for your interview on time, or even a few minutes early.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vacuum Metalizer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.