Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Valance Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Valance Cutter so you can tailor your answers to impress potential employers.

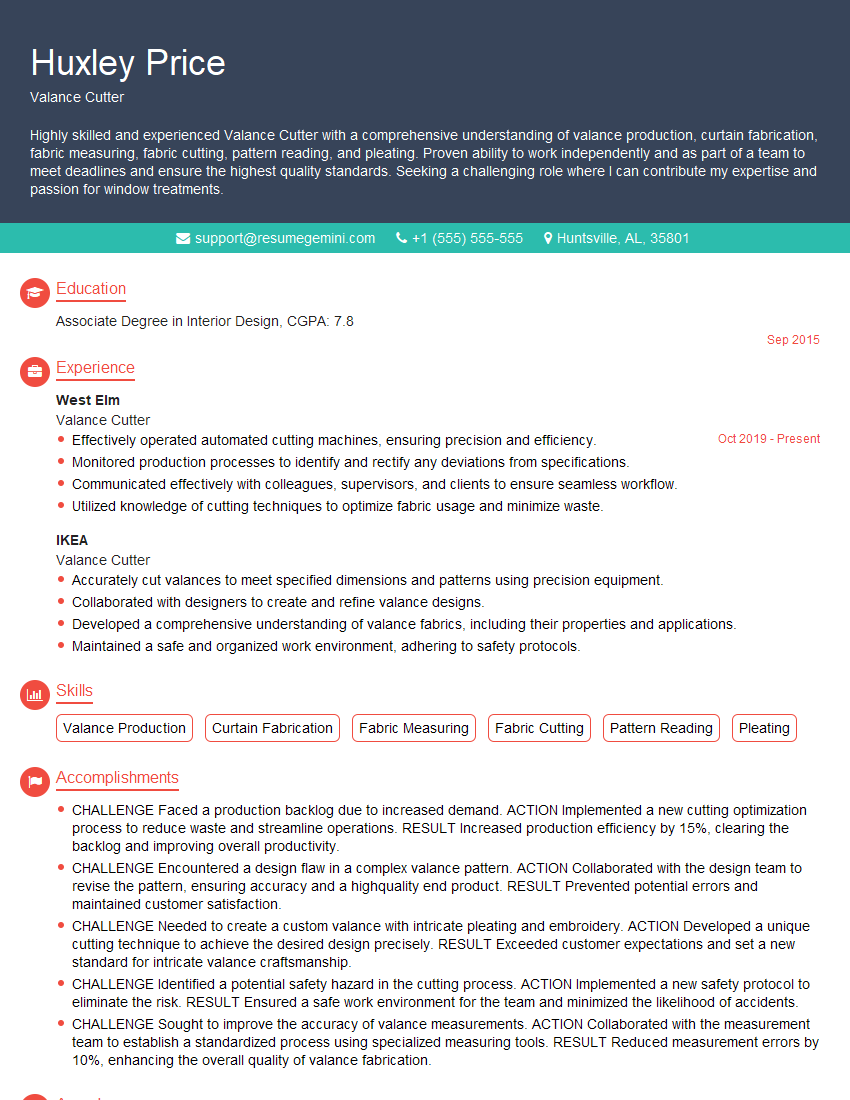

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valance Cutter

1. Can you describe the process of cylindrical grinding?

Cylindrical grinding is a machining process used to produce cylindrical surfaces on metal workpieces. The process involves using a rotating grinding wheel to remove material from the workpiece, resulting in a smooth, precise cylindrical surface.

- The workpiece is mounted on a rotating chuck or table.

- The grinding wheel is brought into contact with the workpiece and rotates at a high speed.

- The grinding wheel is fed into the workpiece, removing material and creating the desired cylindrical surface.

- The grinding wheel is dressed periodically to maintain its shape and cutting ability.

2. What are the different types of cylindrical grinding machines?

- Centerless grinding: The workpiece is supported by a rotating grinding wheel and a regulating wheel, eliminating the need for a chuck or table.

- Center-type grinding: The workpiece is held between two centers, one of which is driven to rotate the workpiece.

- Internal grinding: The grinding wheel is inserted into the workpiece bore to create a cylindrical surface on the inside diameter.

- Surface grinding: The grinding wheel moves across the surface of the workpiece, removing material to create a flat surface.

3. What are the key factors that affect the quality of a cylindrical grind?

- Wheel selection: The type and grade of grinding wheel used will impact the surface finish, accuracy, and efficiency of the grinding process.

- Workpiece material: The hardness, strength, and composition of the workpiece material will affect the grinding parameters and wheel selection.

- Grinding parameters: The speed, feed rate, and depth of cut will determine the material removal rate, surface finish, and accuracy of the grind.

- Coolant: Coolant is used to lubricate the grinding process, reduce friction, and remove chips.

- Dressing: Regular dressing of the grinding wheel is essential to maintain its shape, cutting ability, and surface finish.

4. How do you troubleshoot common problems in cylindrical grinding?

- Poor surface finish: This can be caused by a dull grinding wheel, incorrect grinding parameters, or vibration in the machine.

- Inaccuracy: Inaccurate grinding can be caused by excessive deflection in the workpiece or machine, incorrect wheel alignment, or thermal expansion.

- Burn marks: Burn marks on the workpiece indicate excessive heat generation during grinding, which can be caused by too high grinding speeds or feed rates.

- Chatter: Chatter during grinding is often caused by vibration or resonance in the machine or workpiece.

5. What are the safety precautions that should be taken when operating a cylindrical grinder?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Inspect the machine and grinding wheel before each use.

- Secure the workpiece properly to prevent it from moving during grinding.

- Use coolant to lubricate the process and prevent overheating.

- Follow the manufacturer’s recommended grinding parameters and wheel dressing procedures.

6. How do you calculate the grinding wheel speed and feed rate for a given grinding operation?

- Wheel speed: The wheel speed is determined based on the workpiece material, wheel type, and desired surface finish.

- Feed rate: The feed rate determines the amount of material removed per pass and is adjusted based on the desired accuracy and surface finish.

7. What are the different types of grinding wheels used in cylindrical grinding?

- Abrasive type: Common abrasive types include aluminum oxide, silicon carbide, and cubic boron nitride.

- Bond type: The bond holds the abrasive grains together and can be resinoid, vitrified, or metal.

- Grain size: The grain size refers to the size of the abrasive particles and influences the surface finish.

- Wheel shape: The wheel shape is determined by the grinding operation and can be cylindrical, cup, or dish.

8. How do you measure the accuracy of a cylindrical grind?

- Micrometer: A micrometer can be used to measure the diameter and roundness of the workpiece.

- Dial indicator: A dial indicator can be used to measure the taper and straightness of the workpiece.

- Coordinate measuring machine (CMM): A CMM can be used to measure complex shapes and dimensions with high accuracy.

9. What are some advanced techniques used in cylindrical grinding?

- Creep feed grinding: A technique that uses very low feed rates to achieve high surface finish and accuracy.

- CBN grinding: A technique that uses cubic boron nitride wheels to grind hard materials.

- PCD grinding: A technique that uses polycrystalline diamond wheels to grind hard and brittle materials.

- Laser-assisted grinding: A technique that uses a laser to preheat the workpiece, reducing grinding forces and improving surface finish.

10. What are the career opportunities for a skilled cylindrical grinder?

- Manufacturing engineer

- Production supervisor

- Quality control inspector

- Tool and die maker

- Maintenance technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valance Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valance Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Valance Cutter is responsible for cutting and preparing fabrics for the creation of valances, which are decorative window treatments. The key job responsibilities include:

1. Fabric Preparation

Preparing fabrics by inspecting, measuring, and marking the fabric according to the given specifications or patterns.

2. Fabric Cutting

Cutting fabric precisely using a variety of tools such as rotary cutters, scissors, and straight edges to create the desired shapes and sizes.

3. Hemming and Finishing

Hemming and finishing the cut fabric to give it a clean and professional appearance, using techniques such as blind stitching, serging, or pinking.

4. Quality Control

Ensuring that the cut and finished valances meet the required quality standards by inspecting and checking for accuracy and precision.

5. Machine Maintenance

Maintaining and cleaning the cutting equipment regularly to ensure optimal performance and safety.

Interview Tips

To ace an interview for a Valance Cutter position, candidates should consider the following tips:

1. Research the Company and Role

Learn about the company, its culture, and the specific requirements of the Valance Cutter role. This will help you understand the company’s expectations and align your answers with their needs.

2. Highlight Relevant Experience

Emphasize your past experience in fabric cutting, sewing, or related fields. Quantify your accomplishments with specific examples that demonstrate your skills and abilities.

3. Showcase Attention to Detail

Convey your keen attention to detail and precision in your work. Share examples of how you have ensured accuracy and quality in previous projects.

4. Be Enthusiastic and Eager to Learn

Express your passion for fabric work and your willingness to learn new techniques and technologies. Show that you are eager to contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valance Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!