Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Valve Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

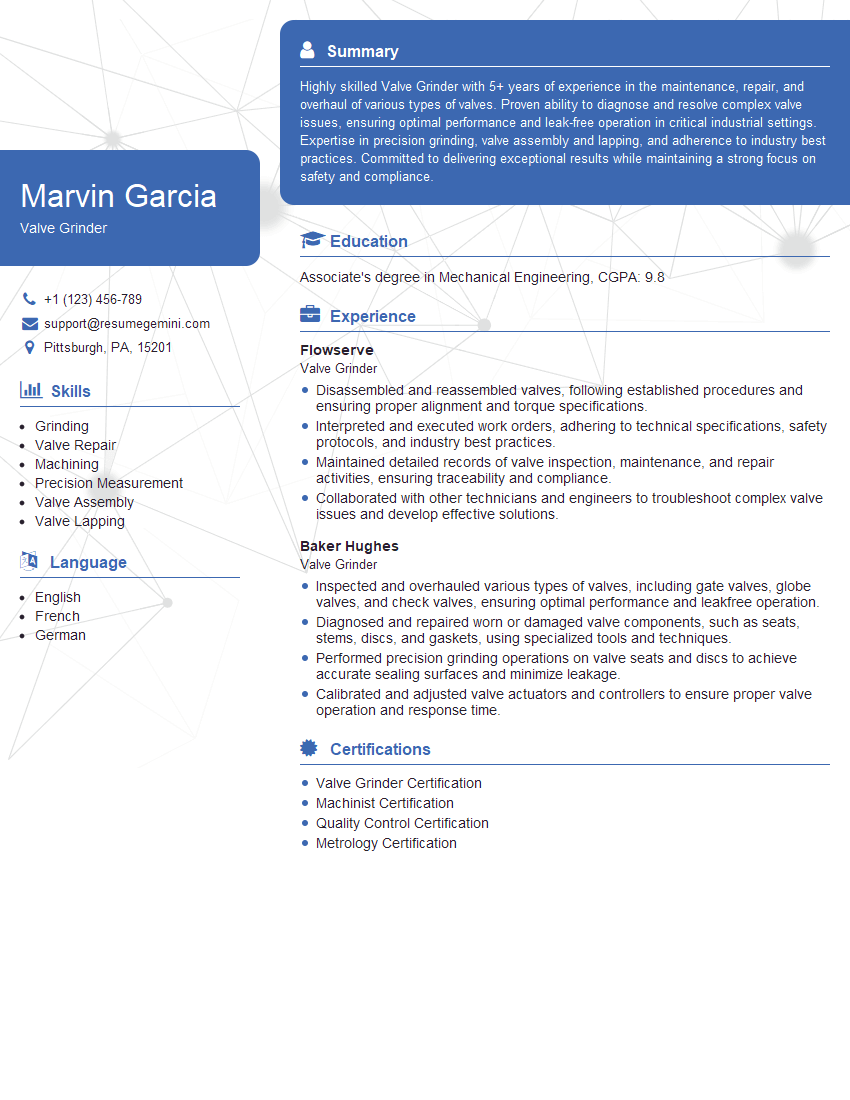

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Grinder

1. Explain the process of valve grinding?

Valve grinding is the process of resurfacing the valve seat and valve face to ensure proper sealing and compression in an engine. The process involves the following steps:

- Removing the cylinder head from the engine.

- Disassembling the valve train and removing the valves.

- Using a valve grinding machine or hand tool to grind the valve face and seat.

- Checking the valve clearances and adjusting as necessary.

- Reassembling the valve train and reinstalling the cylinder head.

2. What are the different types of valve grinders and their uses?

Manual valve grinders:

- Require manual operation using a hand crank or lever.

- Suitable for low-volume work or hobbyists.

Electric valve grinders:

- Powered by an electric motor for increased efficiency and speed.

- Used in professional shops and for high-volume work.

Pneumatic valve grinders:

- Operated using compressed air for portability and ease of use.

- Ideal for on-site work or in areas with limited electrical access.

3. What are the key factors to consider when grinding valves?

When grinding valves, it is important to consider the following factors:

- Valve seat angle and width: These must match the manufacturer’s specifications for proper sealing.

- Valve face finish: The surface should be smooth and free of imperfections to prevent leaks.

- Valve clearances: These must be set correctly to ensure optimal engine performance.

- Valve material: Different materials require specific grinding techniques and abrasives.

4. How do you ensure the accuracy of valve grinding?

To ensure accuracy in valve grinding, it is crucial to:

- Use a high-quality valve grinding machine or tool.

- Follow the manufacturer’s instructions for the equipment and abrasives used.

- Check the valve seat and face angles using a dial indicator or other measuring tool.

- Measure the valve clearances and adjust as necessary.

5. What are some common problems encountered during valve grinding and how do you resolve them?

Common problems encountered during valve grinding include:

- Leaking valves: This can be caused by incorrect valve seat angle, poor surface finish, or improper valve clearances.

- Burnt or pitted valves: This can occur due to excessive heat or abrasives, and may require replacement of the valves.

- Valve sticking: This can be caused by dirt or debris in the valve train, or by incorrect valve clearances.

6. What are the safety precautions to be taken when valve grinding?

When performing valve grinding, it is important to observe the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure the valve grinding machine is properly grounded and operated.

- Handle valves with care to avoid cuts or injuries.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

7. What are the different types of abrasives used in valve grinding and their characteristics?

Common abrasives used in valve grinding include:

- Aluminum oxide: Versatile and widely used, suitable for most materials.

- Silicon carbide: Harder than aluminum oxide, suitable for harder materials like stainless steel.

- Diamond: The hardest abrasive, providing the finest finish but requires specialized equipment.

8. How do you adjust valve clearances after valve grinding?

Valve clearances can be adjusted after valve grinding using the following steps:

- Measure the valve clearances using a feeler gauge.

- Adjust the valve clearances by loosening or tightening the valve adjusters.

- Set the valve clearances to the manufacturer’s specifications.

9. What are the signs that indicate a valve grinding job is necessary?

Signs that may indicate the need for valve grinding include:

- Reduced engine performance or efficiency.

- Excessive exhaust smoke.

- Knocking or tapping sounds from the engine.

- Oil leaks around the valve cover.

10. How often should valves be ground?

The frequency of valve grinding depends on several factors, including the type of engine, driving conditions, and maintenance practices. Generally, valves should be ground as per the manufacturer’s recommended intervals, which can range from 30,000 to 100,000 kilometers or more.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Valve grinders play a vital role in maintaining the performance and efficiency of internal combustion engines. Their primary responsibilities include:

1. Valve Grinding and Lapping

Grind and lap valves to ensure proper seating and sealing, reducing leakage and optimizing engine performance.

2. Valve Inspection and Assessment

Inspect and assess valves for wear, damage, or defects, identifying potential issues and ensuring engine reliability

3. Valve Seat Cutting

Cut and refinish valve seats to restore their optimal shape and alignment, ensuring proper valve sealing

4. Valve Guide Reaming

Ream and hone valve guides to ensure smooth and precise valve movement, preventing excessive wear

Interview Tips

To ace an interview for a valve grinder position, candidates should prepare thoroughly and showcase their skills and experience. Here are some tips to help you prepare:

1. Research the Company and Role

Research the company, their industry, and the specific responsibilities of the valve grinder role. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in valve grinding and related tasks. Quantify your accomplishments and provide specific examples of your contributions to previous projects.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Consider questions about your technical expertise, problem-solving abilities, and experience with equipment relevant to valve grinding.

4. Be Enthusiastic and Professional

Show your passion for valve grinding and the automotive industry. Maintain a professional demeanor throughout the interview, demonstrating your commitment and interest in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valve Grinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.