Are you gearing up for a career in Valve Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Valve Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

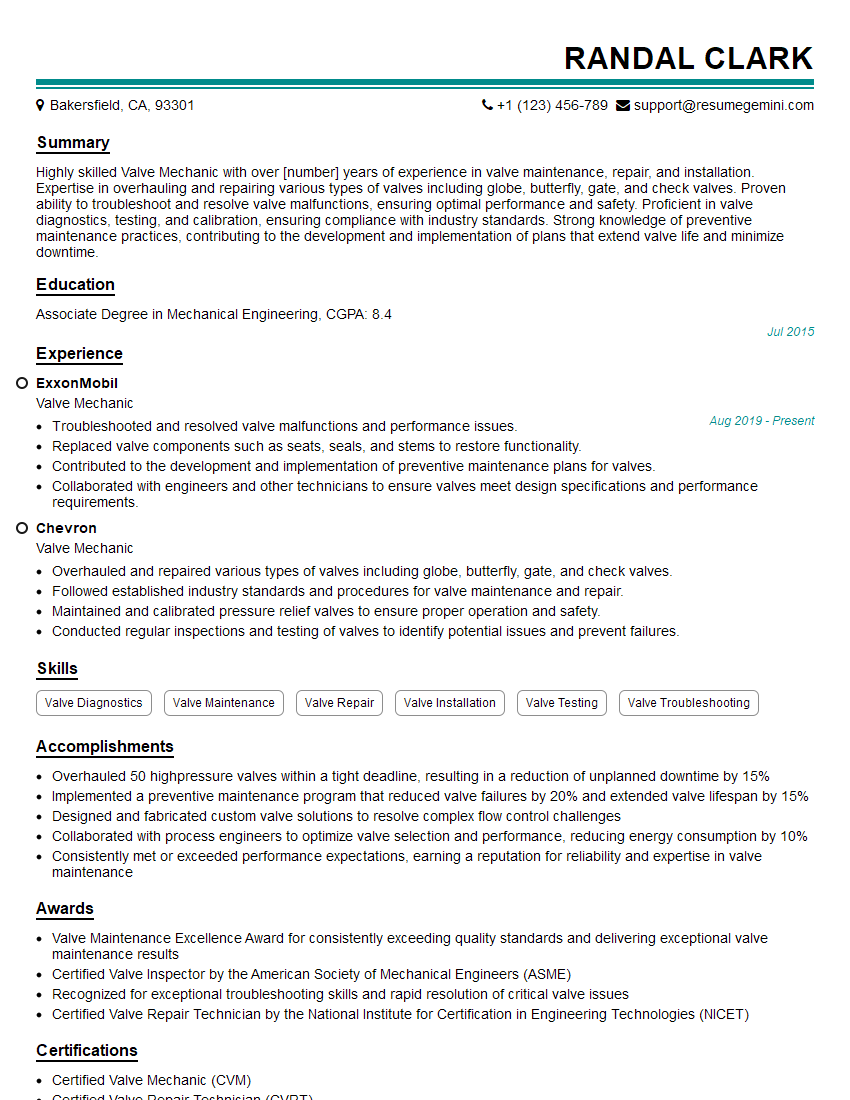

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Mechanic

1. Describe the steps involved in repairing a leaking valve.

The steps involved in repairing a leaking valve include:

- Identifying the type of valve and the cause of the leak

- Isolating the valve and draining the fluid from the system

- Disassembling the valve and inspecting the components for damage or wear

- Replacing or repairing the damaged components, such as the valve seat, disc, or packing

- Reassembling the valve and testing it for leaks

2. What are the different types of valve actuators and their applications?

- Manual actuators: Operated by hand, these actuators are commonly used in low-pressure applications and for valves that are infrequently operated

- Pneumatic actuators: Powered by compressed air, these actuators are fast-acting and can be used in a wide range of applications

- Electric actuators: Powered by electricity, these actuators provide precise control and can be integrated with automation systems

- Hydraulic actuators: Powered by hydraulic fluid, these actuators offer high force output and are suitable for heavy-duty applications

3. What are the common causes of valve failure and how can they be prevented?

Common causes of valve failure include:

- Corrosion: Can be prevented by using corrosion-resistant materials and coatings

- Wear and tear: Can be minimized by using high-quality materials and proper maintenance

- Improper installation: Can be avoided by following manufacturer’s instructions and using qualified technicians

- Over-pressurization: Can be prevented by installing pressure relief valves and monitoring system pressure

4. What are the safety precautions that must be observed when working on valves?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat

- Identify and isolate the valve before starting work

- Release pressure from the system before disassembling the valve

- Use proper tools and techniques to avoid damaging the valve or causing injury

- Inspect the valve and surrounding area for any signs of damage or wear before operating

5. How do you determine the correct valve size for a particular application?

- Consider the flow rate and pressure requirements of the system

- Refer to valve sizing charts or use online calculators to determine the appropriate valve size

- Select a valve with a flow capacity that is greater than the required flow rate

- Consider the valve’s pressure rating to ensure it can withstand the system pressure

- Take into account the available space and mounting requirements

6. What are the advantages of using ball valves over other types of valves?

- Low pressure drop: Ball valves offer minimal resistance to flow, resulting in reduced pressure loss

- Quick operation: Ball valves can be opened or closed quickly by rotating the ball 90 degrees

- Compact design: Ball valves have a relatively small footprint, making them suitable for confined spaces

- Reliability: Ball valves are durable and have a long lifespan with minimal maintenance

- Versatility: Ball valves can be used in a wide range of applications, including water, gas, and oil systems

7. How do you troubleshoot a solenoid valve that is not functioning properly?

- Check the electrical connections and power supply

- Test the solenoid coil for continuity

- Inspect the valve diaphragm and spring for damage or wear

- Clean the valve seat and plunger

- Replace any faulty components and reassemble the valve

8. What are the key features of a high-performance butterfly valve?

- Low pressure drop: Streamlined design minimizes flow resistance

- Tight shutoff: Precise machining and sealing materials prevent leakage

- Corrosion resistance: Constructed from materials that withstand harsh environments

- Quick operation: Quarter-turn actuation for fast and efficient operation

- Low maintenance: Durable design with minimal moving parts

9. What are the different types of valve testing methods and when are each of them used?

Hydrostatic Testing:- Used to test valves for leaks and structural integrity

- Involves applying high pressure water to the valve while it is closed

- Used to test valves for leaks and actuation functionality

- Involves applying compressed air to the valve and monitoring for pressure loss

- Used to detect cracks and other defects in valves

- Involves listening for high-frequency sound emissions generated by defects under stress

10. How do you maintain and calibrate a pressure relief valve?

- Inspection: Regularly check the valve for leaks, corrosion, and damage

- Testing: Periodically test the valve by manually activating it to ensure proper opening pressure

- Calibration: Adjust the valve’s spring tension to achieve the desired opening pressure

- Documentation: Record all maintenance and calibration activities for traceability and compliance purposes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Valve Mechanics are responsible for the maintenance, repair, and installation of various types of valves found in industrial and commercial settings. Their main duties include:1. Valve Maintenance and Repair

Inspect and assess valves for proper operation and identify any defects or issues.

- Disassemble and reassemble valves to identify and replace worn or damaged components.

- Lubricate, adjust, and calibrate valves to ensure optimal performance.

2. Valve Installation

Read and interpret blueprints, schematics, and work orders to understand valve installation requirements.

- Install new valves in accordance with specifications and industry standards.

- Connect valves to piping systems, ensuring proper alignment and tightness.

3. Troubleshooting and Diagnostics

Identify and diagnose malfunctions or performance issues in valves.

- Use specialized tools and equipment to test valve operation and pinpoint problems.

- Recommend and implement solutions to resolve valve issues, ensuring system efficiency and safety.

4. Documentation and Reporting

Maintain detailed records of valve maintenance, repair, and installation activities.

- Create reports on valve inspections, repairs, and installations for management and regulatory compliance.

- Document valve specifications, materials, and any modifications made.

Interview Tips

1. Research the Company and Industry

Gather information about the company’s business, products, and industry to demonstrate your genuine interest and understanding of their operations.

- Visit the company website, read industry publications, and connect with professionals in the field before the interview.

- Tailor your resume and cover letter to highlight your skills and experience that align with the specific requirements of the position.

2. Practice Your Technical Skills

Review common valve types, maintenance procedures, and troubleshooting techniques to refresh your knowledge.

- Consider taking online courses or reviewing technical manuals to enhance your understanding of valve mechanics.

- Be prepared to discuss specific valve repair and installation scenarios, explaining your approach and the tools you would use.

3. Highlight Your Problem-Solving Abilities

Emphasize your ability to diagnose and resolve complex valve issues.

- Provide examples from your previous experience where you successfully identified and solved valve problems, leading to improved system performance.

- Discuss your analytical skills and how you approach troubleshooting, considering different factors and potential solutions.

4. Showcase Your Safety Awareness

Valve mechanics work in industrial settings where safety is paramount.

- Demonstrate your knowledge of safety protocols, including proper handling of valves, use of personal protective equipment (PPE), and adherence to lockout/tagout procedures.

- Convey your commitment to maintaining a safe and efficient work environment.

5. Prepare for Behavioral Questions

Anticipate behavioral interview questions that explore your teamwork, communication, and problem-solving skills.

- Use the STAR method (Situation, Task, Action, Result) to effectively answer behavioral questions, providing specific examples from your experience.

- Prepare thoughtful questions for the interviewer to demonstrate your engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valve Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!