Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Valve Setter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Valve Setter so you can tailor your answers to impress potential employers.

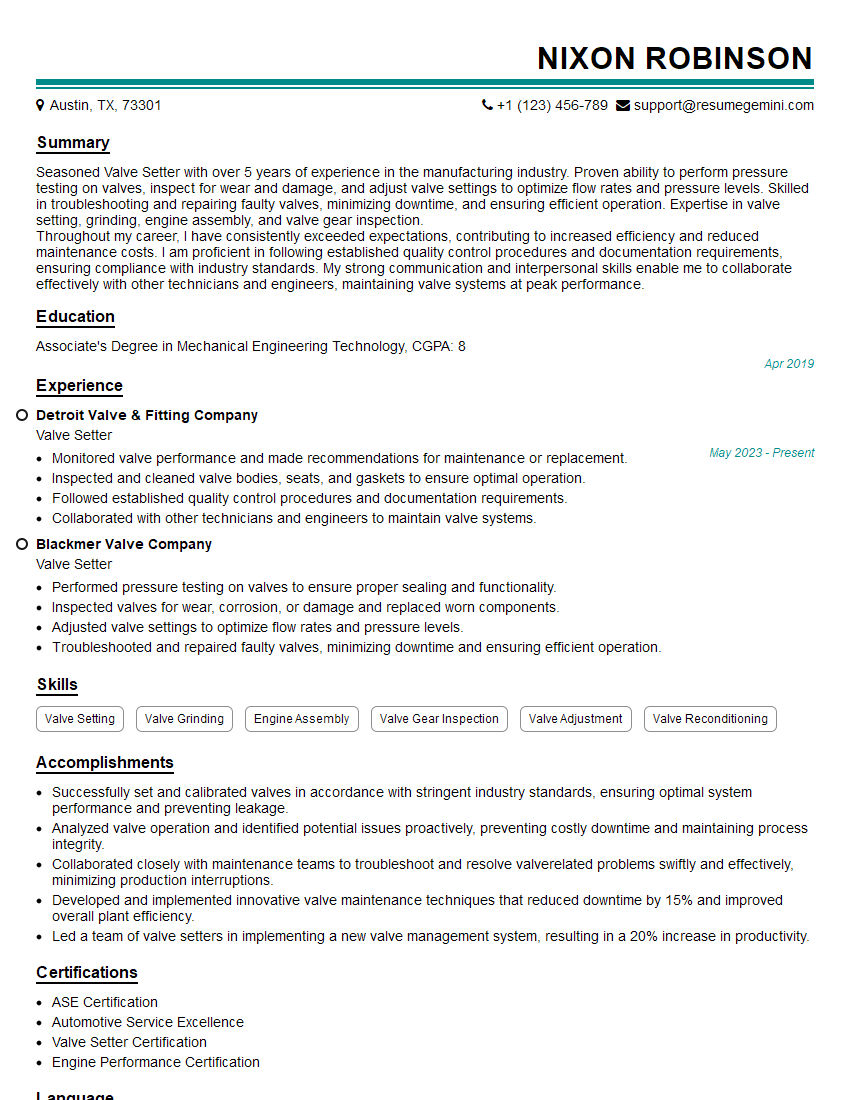

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Setter

1. What are the different types of valve seats and their applications?

- Flat valve seats: These are the most common type of valve seat and are used in a wide variety of applications. They are relatively easy to manufacture and maintain, and they provide a good seal between the valve and the seat.

- Beveled valve seats: These valve seats are similar to flat valve seats, but they have a beveled edge. This beveled edge helps to create a better seal between the valve and the seat, and it can also help to reduce wear and tear on the valve.

- Dished valve seats: These valve seats have a dished shape, which helps to create a more positive seal between the valve and the seat. Dished valve seats are often used in high-performance engines, where a positive seal is critical.

- Conical valve seats: These valve seats have a conical shape, which helps to create a very precise seal between the valve and the seat. Conical valve seats are often used in racing engines, where a very precise seal is essential.

2. What are the different methods of valve seat machining?

Cutting

- Single-point cutting: This is the most common method of valve seat machining. A single-point cutting tool is used to remove material from the valve seat, and the tool is guided by a template or a CNC machine.

- Multi-point cutting: This method uses a cutting tool with multiple cutting edges to remove material from the valve seat. Multi-point cutting is faster than single-point cutting, but it can be more difficult to control the accuracy of the cut.

Grinding

- Grinding is a process of removing material from the valve seat using an abrasive wheel. Grinding can be used to create a very precise finish on the valve seat, but it can also be a time-consuming process.

3. What are the different factors that affect valve seat wear?

- Valve material: The material of the valve can have a significant impact on valve seat wear. Harder valve materials will wear less quickly than softer valve materials.

- Valve seat material: The material of the valve seat can also affect valve seat wear. Harder valve seat materials will wear less quickly than softer valve seat materials.

- Valve spring pressure: The pressure of the valve spring can affect valve seat wear. Higher valve spring pressure will cause the valve to seat more firmly against the seat, which can lead to increased wear.

- Valve timing: The timing of the valve can also affect valve seat wear. Valves that open and close too quickly can cause the valve to bounce off the seat, which can lead to increased wear.

4. What are the signs of excessive valve seat wear?

- Loss of compression: Excessive valve seat wear can lead to a loss of compression, which can cause the engine to run poorly.

- Increased oil consumption: Excessive valve seat wear can also lead to increased oil consumption, as oil can leak past the valve seats into the combustion chamber.

- Engine misfire: Excessive valve seat wear can also cause the engine to misfire, as the valves may not be able to seal properly.

5. What are the steps involved in valve seat reconditioning?

- Remove the valve.

- Inspect the valve seat for wear and damage.

- Machine the valve seat as necessary to remove any wear or damage.

- Clean the valve seat and valve.

- Reinstall the valve.

6. What are the different tools and equipment used in valve seat reconditioning?

- Valve seat cutter

- Valve seat grinder

- Valve spring compressor

- Valve lapping tool

- Micrometer

- Dial indicator

7. What are the safety precautions that must be taken when performing valve seat reconditioning?

- Always wear safety glasses and gloves.

- Use a valve spring compressor to safely remove and install the valve springs.

- Be careful not to overtighten the valve seat cutter or grinder.

- Never operate the valve seat cutter or grinder without a guard in place.

- Always clean up any metal shavings or debris after completing the valve seat reconditioning process.

8. What are the benefits of using a valve seat insert?

- Valve seat inserts can help to extend the life of the valve seat.

- Valve seat inserts can help to improve the sealing of the valve.

- Valve seat inserts can help to reduce the amount of wear on the valve.

9. What are the different types of valve seat inserts?

- Solid valve seat inserts

- Laminated valve seat inserts

- Coated valve seat inserts

10. What are the factors to consider when selecting a valve seat insert?

- The material of the valve seat insert

- The size of the valve seat insert

- The type of engine in which the valve seat insert will be used

11. What are the steps involved in installing a valve seat insert?

- Remove the old valve seat insert.

- Clean the valve seat.

- Apply a thin layer of sealant to the valve seat.

- Install the new valve seat insert.

- Reinstall the valve.

12. What are the safety precautions that must be taken when installing a valve seat insert?

- Always wear safety glasses and gloves.

- Use a valve spring compressor to safely remove and install the valve springs.

- Be careful not to overtighten the valve seat insert.

- Never operate the valve seat installer without a guard in place.

- Always clean up any metal shavings or debris after completing the valve seat insert installation process.

13. What are the signs of a failed valve seat insert?

- Loss of compression

- Increased oil consumption

- Engine misfire

- Valve seat insert protrusion

14. What are the causes of valve seat insert failure?

- Improper installation

- Excessive heat

- Corrosion

- Wear

15. How can valve seat insert failure be prevented?

- Proper installation

- Use of high-quality valve seat inserts

- Regular engine maintenance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Valve Setters play the crucial role of ensuring a vehicle’s engine operates efficiently. Their responsibilities include:1. Valve Adjustment

Using specialized tools and measuring instruments, they set and adjust valves within specified tolerances to ensure optimal engine performance and longevity.

2. Valve Train Inspection

Regularly inspect valve train components, including timing belts and chains, camshafts, rocker arms, and valve springs, to detect potential wear or damage that could impair engine function.

3. Valve and Seat Grinding

Grind valves and seats using precision machines to restore proper sealing surfaces and optimize valve closure. This ensures the engine maintains compression and avoids valve leaks.

4. Engine Performance Testing

Monitor engine performance using diagnostic tools, including compression tests and leak-down tests, to identify potential issues and ensure proper valve operation after adjustments or repairs.

Interview Tips

To ace an interview for a Valve Setter position, candidates should consider the following tips:1. Research the Company and Role

Thoroughly research the company’s background, values, and the specific requirements of the Valve Setter position. This will demonstrate your enthusiasm and preparedness.

2. Highlight Technical Skills and Experience

Emphasize your technical proficiency in valve adjustment, engine diagnostics, and related skills. Showcase your experience working with specialized tools and diagnosing and resolving engine issues.

3. Showcase Attention to Detail and Precision

Valve Setters must possess meticulous attention to detail and precision in their work. Highlight your ability to work with small components, follow precise measurements, and ensure accuracy in your adjustments.

4. Practice Common Interview Questions

Prepare for common interview questions related to your technical abilities, experience, and teamwork skills. Practice answering them concisely and confidently.

5. Prepare Specific Examples

When responding to interview questions, provide specific examples of how you successfully diagnosed and resolved valve-related issues, demonstrating your skills and problem-solving abilities.

6. Ask Thoughtful Questions

At the end of the interview, ask insightful questions about the company’s operations, the role’s responsibilities, or the industry trends. This shows your genuine interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valve Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!