Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Varnish Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

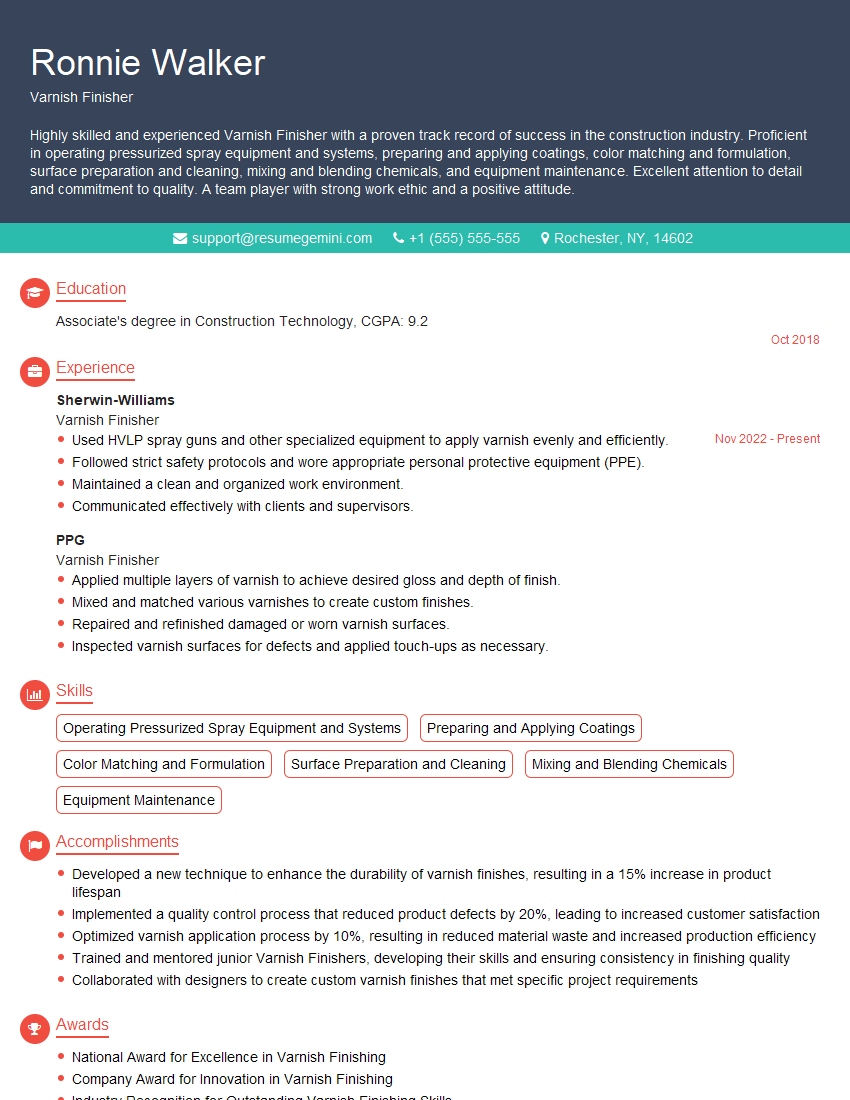

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnish Finisher

1. Can you elaborate on the different types of varnishes available and their specific applications?

- Water-based varnishes: These are the most commonly used type of varnish and are ideal for interior wood surfaces because they are easy to apply and dry quickly.

- Oil-based varnishes: These varnishes are more durable than water-based varnishes and are ideal for exterior wood surfaces because they are resistant to moisture and UV rays.

- Polyurethane varnishes: These varnishes are the most durable type of varnish and are ideal for high-traffic areas because they are resistant to wear and tear.

2. What are the key factors to consider when choosing the right varnish for a particular application?

Substrate

- The type of wood you are varnishing will determine the type of varnish you need to use.

- For example, water-based varnishes are not suitable for oily woods.

Finish

- The finish you want to achieve will also determine the type of varnish you need to use.

- For example, if you want a high-gloss finish, you will need to use a varnish that is specifically designed for that purpose.

Environment

- The environment in which the varnish will be used will also determine the type of varnish you need to use.

- For example, if you are varnishing an exterior surface, you will need to use a varnish that is resistant to moisture and UV rays.

3. What are the steps involved in preparing a surface for varnishing?

- Clean the surface to remove any dirt or debris.

- Sand the surface to smooth it out.

- Remove any dust from the surface.

4. What are the proper techniques for applying varnish?

- Apply the varnish in thin, even coats.

- Allow each coat to dry completely before applying the next coat.

- Sand lightly between coats to smooth out any imperfections.

5. What are the common problems that can occur when varnishing and how can they be fixed?

Bubbles

- Bubbles can be caused by a number of factors, including applying the varnish too thickly or not allowing the previous coat to dry completely.

- To fix bubbles, pop them with a pin or needle and then sand the area smooth.

Runs

- Runs can be caused by applying the varnish too thickly or not allowing the previous coat to dry completely.

- To fix runs, sand the area smooth and then re-apply the varnish.

Blushing

- Blushing is a condition that can occur when the varnish is applied in a humid environment.

- To fix blushing, allow the varnish to dry completely and then sand the area smooth.

6. What are the safety precautions that should be taken when varnishing?

- Wear a respirator to avoid inhaling the fumes from the varnish.

- Wear gloves to protect your skin from the varnish.

- Work in a well-ventilated area.

7. What are the different types of brushes that can be used for varnishing and what are the advantages and disadvantages of each type?

Natural bristle brushes

- Advantages: Natural bristle brushes hold more varnish and produce a smoother finish.

- Disadvantages: Natural bristle brushes are more expensive and can shed bristles.

Synthetic bristle brushes

- Advantages: Synthetic bristle brushes are less expensive and do not shed bristles.

- Disadvantages: Synthetic bristle brushes do not hold as much varnish and can produce a less smooth finish.

Foam brushes

- Advantages: Foam brushes are inexpensive and easy to use.

- Disadvantages: Foam brushes do not hold as much varnish and can produce a less durable finish.

8. What are the different types of sprayers that can be used for varnishing and what are the advantages and disadvantages of each type?

HVLP sprayers

- Advantages: HVLP sprayers produce a finer finish than airless sprayers and use less varnish.

- Disadvantages: HVLP sprayers are more expensive than airless sprayers and require more setup time.

Airless sprayers

- Advantages: Airless sprayers are less expensive than HVLP sprayers and can apply varnish more quickly.

- Disadvantages: Airless sprayers produce a coarser finish than HVLP sprayers and use more varnish.

9. What are the different techniques for achieving different finishes when varnishing?

High-gloss finish

- Apply multiple thin coats of varnish and sand lightly between coats.

Matte finish

- Apply a single coat of varnish and do not sand it.

Satin finish

- Apply a few thin coats of varnish and sand lightly between coats until the desired sheen is achieved.

10. What are the latest trends in varnishing and what are the benefits of using these techniques?

UV-curable varnishes

- UV-curable varnishes are cured by exposure to ultraviolet light, which results in a faster drying time and a more durable finish.

Waterborne varnishes

- Waterborne varnishes are less toxic than traditional varnishes and are easier to clean up.

Hybrid varnishes

- Hybrid varnishes combine the benefits of both oil-based and water-based varnishes, resulting in a durable and easy-to-apply finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnish Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnish Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Varnish Finishers are responsible for completing the final finishing touches to products and surfaces using various varnishes, stains, and other coatings. Their duties involve preparing surfaces, applying coatings, and ensuring the uniform and aesthetically pleasing appearance of finished products.

1. Surface Preparation

Before applying coatings, Varnish Finishers must prepare the surfaces to ensure proper adhesion and a smooth finish. They may sand, clean, or fill imperfections to create a clean and even surface.

- Sanding surfaces to remove rough edges or imperfections

- Cleaning surfaces to remove dirt, grease, or other contaminants

- Filling gaps or holes using appropriate materials

2. Varnish and Coating Application

Varnish Finishers apply varnishes, stains, and other coatings to protect and enhance the appearance of surfaces. They carefully follow application instructions and use specialized equipment to achieve a consistent and durable finish.

- Mixing and preparing coatings according to specifications

- Applying varnishes and coatings using brushes, rollers, or spray equipment

- Controlling the thickness and evenness of coatings

3. Finishing and Polishing

After applying coatings, Varnish Finishers perform finishing and polishing techniques to refine the appearance and durability of the surface. They may buff, sand, or polish the surface to achieve the desired sheen and protection.

- Buffing surfaces to remove excess coating and create a smooth finish

- Sanding surfaces to smooth out uneven areas or imperfections

- Polishing surfaces to enhance shine, clarity, and depth

4. Quality Control

Varnish Finishers are responsible for ensuring the quality of their work. They inspect finished products for defects, imperfections, or inconsistencies. They make necessary adjustments or touch-ups to ensure the highest standards are met.

- Inspecting finished surfaces for any defects or blemishes

- Re-applying coatings or performing touch-ups as needed

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for a Varnish Finisher interview can significantly increase your chances of success. Here are some tips and strategies to help you stand out:

1. Research the Company and Position

Take the time to learn about the company’s history, values, and products. Familiarize yourself with the specific requirements of the Varnish Finisher position and how your skills and experience align with them.

- Visit the company’s website and social media pages

- Read industry publications and articles

- Connect with current or former employees on LinkedIn

2. Practice Your Answers

Commonly asked interview questions for Varnish Finishers include those about your experience, skills, and attention to detail. Prepare thoughtful and concise answers that highlight your qualifications and enthusiasm for the role.

- Prepare an elevator pitch that summarizes your skills and experience

- Practice answering questions about your surface preparation techniques

- Emphasize your ability to work with precision and attention to detail

3. Showcase Your Portfolio

If possible, bring a portfolio or samples of your previous work to the interview. This will allow you to visually demonstrate your skills and showcase the quality of your craftsmanship.

- Include examples of different finishes and techniques

- Highlight any unique or challenging projects you have completed

- Be prepared to discuss your creative process and the materials you use

4. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Wear clean and pressed clothing

- Consider wearing safety glasses or gloves if appropriate

- Arrive 5-10 minutes early to show punctuality

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Varnish Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!