Feeling lost in a sea of interview questions? Landed that dream interview for Varnish Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Varnish Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

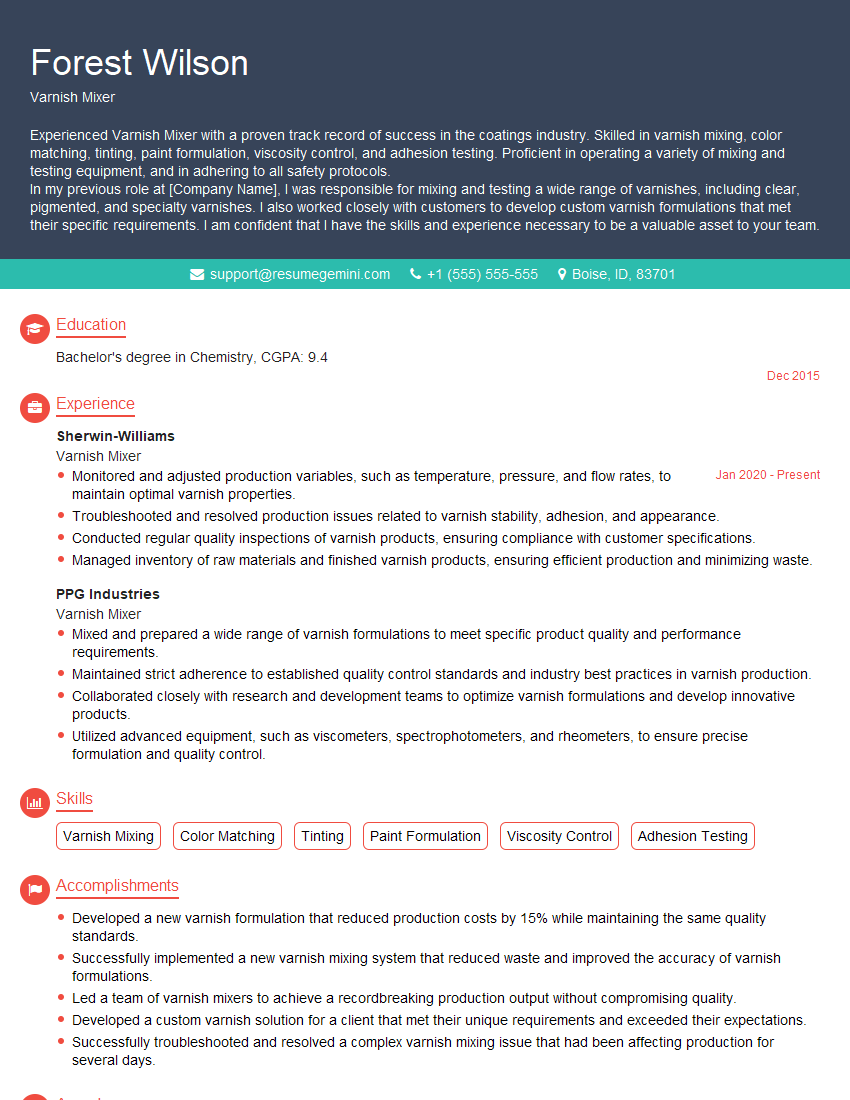

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnish Mixer

1. what are the different types of varnishes used in the printing industry?

There are several types of varnishes used in the printing industry, including:

- Oil-based varnishes: These varnishes are made from drying oils, such as linseed oil or tung oil, and are known for their durability and resistance to water and solvents.

- Water-based varnishes: These varnishes are made from water and acrylic resins, and are known for their quick drying time and low odor.

- UV-curable varnishes: These varnishes are cured using ultraviolet light, and are known for their fast curing time and high gloss finish.

2. What are the key properties of a good varnish?

Durability:

- A good varnish should be durable enough to withstand wear and tear, and should not easily chip or peel.

Water and solvent resistance:

- A good varnish should be resistant to water and solvents, so that it can protect the printed product from moisture and spills.

Gloss or matte finish:

- A good varnish should have the desired gloss or matte finish, depending on the desired effect.

3. What are the common problems that can occur when using varnish? How do you troubleshoot each of them?

Some common problems that can occur when using varnish include:

- Bubbling: This can occur if the varnish is applied too thickly or if there is moisture present in the substrate.

- Wrinkling: This can occur if the varnish is not evenly applied or if it is applied to a surface that is not properly prepared.

- Yellowing: This can occur if the varnish is exposed to sunlight or heat.

- To troubleshoot bubbling, you can try thinning the varnish with a solvent or applying it in thinner coats.

- To troubleshoot wrinkling, you can try scuffing the surface of the substrate before applying the varnish or applying a primer.

- To troubleshoot yellowing, you can try adding a UV inhibitor to the varnish or storing the finished product in a cool, dark place.

4. What are the different methods for applying varnish?

There are several different methods for applying varnish, including:

- Brush: This is a simple and inexpensive method, but it can be time-consuming and difficult to achieve a uniform finish.

- Roller: This is a faster and more efficient method than brushing, but it can be difficult to avoid bubbles or streaks.

- Spray: This is the most efficient method for applying varnish, but it requires specialized equipment.

5. What are the safety precautions that should be taken when using varnish?

Varnish can be hazardous if not used properly. Some of the safety precautions that should be taken include:

- Wear gloves and a mask when using varnish.

- Work in a well-ventilated area.

- Keep varnish away from heat and open flames.

6. How do you choose the right varnish for a particular printing job?

The type of varnish that you choose for a particular printing job will depend on several factors, including:

- The desired finish: Do you want a glossy, matte, or satin finish?

- The substrate: What type of material are you printing on?

- The end use: Will the printed product be exposed to moisture, sunlight, or other harsh conditions?

7. What are the latest trends in varnish technology?

Some of the latest trends in varnish technology include:

- Water-based varnishes: These varnishes are more environmentally friendly than oil-based varnishes and offer a wider range of finishes.

- UV-curable varnishes: These varnishes offer fast curing times and high gloss finishes, and are becoming increasingly popular for high-end printing applications.

- Nanotechnology: Nanotechnology is being used to develop new types of varnishes that are more durable, water-resistant, and scratch-resistant.

8. What are the different types of varnish mixers?

There are several different types of varnish mixers, including:

- Batch mixers: These mixers are used to mix small batches of varnish.

- Continuous mixers: These mixers are used to mix large batches of varnish on a continuous basis.

- In-line mixers: These mixers are used to mix varnish with other materials, such as inks or coatings.

9. What are the key features to look for when choosing a varnish mixer?

Some of the key features to look for when choosing a varnish mixer include:

- Capacity: How much varnish will the mixer be able to mix?

- Mixing speed: How fast can the mixer mix varnish?

- Ease of use: How easy is the mixer to operate and clean?

- Durability: How long will the mixer last?

10. What are the different types of varnish mixing techniques?

There are several different varnish mixing techniques, including:

- Hand mixing: This is a simple and inexpensive method, but it can be time-consuming and difficult to achieve a uniform mix.

- Machine mixing: This is a more efficient method than hand mixing, but it requires specialized equipment.

- Ultrasonic mixing: This is a high-tech method that uses ultrasonic waves to mix varnish, resulting in a very uniform mix.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnish Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnish Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Varnish Mixers are responsible for preparing and mixing varnishes used in the finishing and protection of various surfaces, such as wood, metal, or plastic. Their primary duties include:

1. Raw Materials Handling

Receiving, inspecting, and appropriately storing raw materials, including resins, solvents, and pigments

2. Formulation Preparation

Following established recipes or working with chemists to determine the appropriate ratios and proportions of varnish ingredients

3. Mixing and Blending

Using specialized equipment and following safety protocols to mix and blend raw materials, ensuring uniformity, viscosity, and desired properties

4. Application Testing

Conducting tests on small batches of varnish to evaluate their performance and make necessary adjustments to the formulation

5. Equipment Maintenance and Calibration

Performing regular maintenance and calibration of mixing equipment to ensure accurate and efficient operation

6. Data Recording and Documentation

Maintaining detailed records of all mixing processes, including ingredient quantities, mixing parameters, and test results

7. Quality Control

Ensuring the quality and consistency of finished varnishes by adhering to established standards and procedures

Interview Tips

Interview preparation is key to demonstrating your skills and standing out from other candidates. Here are some tips to help you ace your interview:

1. Research the Company and Role

Take the time to learn about the company’s history, products, and industry standing. Familiarize yourself with specific job requirements and responsibilities.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions related to your experience, skills, and why you’re interested in the role. Practice answering them out loud to improve your delivery and confidence.

3. Quantify Your Accomplishments

When describing your past experiences, use specific metrics and data to demonstrate your impact. This will help recruiters understand the tangible results of your work.

4. Ask Insightful Questions

Prepare a list of thoughtful questions to ask the interviewer. This shows you’re engaged and interested in the role and company.

5. Dress Professionally and Arrive on Time

Always make a positive first impression by dressing appropriately and arriving on time for your interview.

6. Be Enthusiastic and Positive

Convey your enthusiasm for the role and the company throughout the interview. A positive attitude can make a significant impact.

7. Be Prepared for Technical Questions

Expect to be asked technical questions related to varnish mixing, equipment operation, and quality control. Brush up on your knowledge before the interview.

8. Highlight Your Knowledge of Safety Protocols

Varnish mixing involves handling hazardous materials. Emphasize your adherence to safety guidelines and your understanding of proper handling and storage procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Varnish Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!