Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Varnisher Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

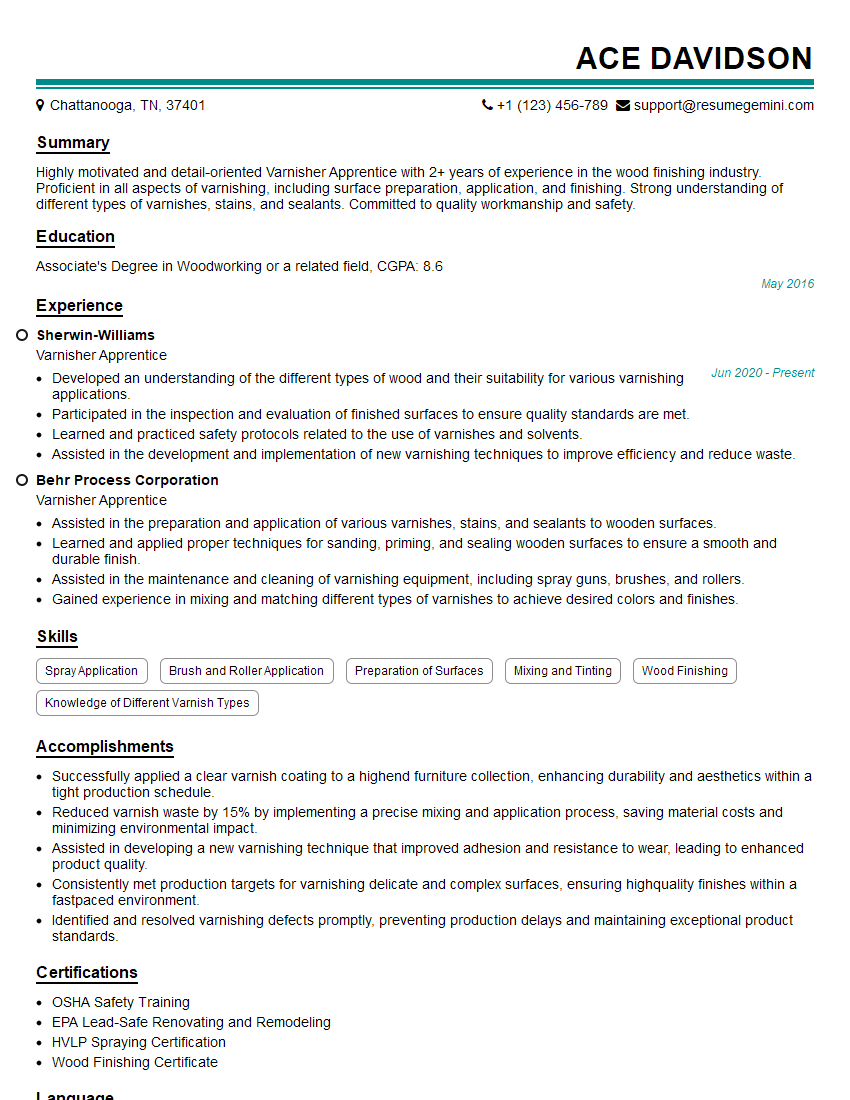

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnisher Apprentice

1. What are the different types of varnishes used in carpentry?

There are different types of varnishes, and each one has specific properties that make it suitable for different applications. Some of the most common types of varnishes used in carpentry include:

- Oil-based varnishes: These varnishes are made from natural oils, such as linseed oil or tung oil. They are durable and provide a high-gloss finish. However, they can be slow to dry and may require multiple coats.

- Water-based varnishes: These varnishes are made from acrylic resins and water. They are easy to apply and dry quickly. However, they may not be as durable as oil-based varnishes.

- Polyurethane varnishes: These varnishes are made from a combination of polyurethane resins and oils. They are durable, provide a high-gloss finish, and are resistant to water and chemicals.

2. What are the steps involved in applying varnish?

Surface preparation

- Clean the surface to be varnished to remove any dust, dirt, or grease.

- Sand the surface lightly with fine-grit sandpaper to smooth any rough spots.

- Remove any sanding dust with a tack cloth.

Varnish application

- Stir the varnish thoroughly before using it.

- Apply the varnish in thin, even coats using a brush, roller, or spray gun.

- Allow each coat to dry completely before applying the next coat.

- Sand the final coat lightly with fine-grit sandpaper to smooth any rough spots.

3. What are the common mistakes to avoid when applying varnish?

There are a few common mistakes that can be avoided when applying varnish. These include:

- Applying the varnish too thickly. This can lead to runs, sags, and bubbles.

- Not allowing each coat to dry completely before applying the next coat. This can lead to the varnish peeling or cracking.

- Sanding the varnish too aggressively. This can remove the finish and damage the wood.

- Using a varnish that is not suitable for the intended application. This can lead to the varnish failing prematurely.

4. What are the safety precautions that should be taken when working with varnish?

Varnish can be flammable and toxic, so it is important to take the following safety precautions when working with it:

- Wear a respirator to avoid inhaling the fumes.

- Wear gloves to protect your skin from contact with the varnish.

- Work in a well-ventilated area.

- Keep the varnish away from heat and open flames.

- Dispose of the varnish and rags used to apply it properly.

5. What are the different types of brushes that can be used to apply varnish?

There are several different types of brushes that can be used to apply varnish, including:

- Natural bristle brushes: These brushes are made from the hair of animals, such as pigs or horses. They are best suited for applying oil-based varnishes.

- Synthetic bristle brushes: These brushes are made from synthetic fibers, such as nylon or polyester. They are best suited for applying water-based varnishes.

- Foam brushes: These brushes are made from a foam material. They are best suited for applying small amounts of varnish or for touching up small areas.

6. What are the different techniques for applying varnish?

There are several different techniques for applying varnish, including:

- Brushing: This is the most common technique for applying varnish. It involves using a brush to apply the varnish in thin, even coats.

- Rolling: This technique is best suited for applying varnish to large, flat surfaces. It involves using a roller to apply the varnish in thin, even coats.

- Spraying: This technique is best suited for applying varnish to large, complex surfaces. It involves using a spray gun to apply the varnish in thin, even coats.

7. What are the different types of finishes that can be achieved with varnish?

There are several different types of finishes that can be achieved with varnish, including:

- Gloss: This finish is characterized by its high shine.

- Semi-gloss: This finish is characterized by its moderate shine.

- Satin: This finish is characterized by its low shine.

- Matte: This finish is characterized by its lack of shine.

8. What are the different factors that affect the drying time of varnish?

The drying time of varnish is affected by several factors, including:

- The type of varnish: Oil-based varnishes take longer to dry than water-based varnishes.

- The thickness of the varnish: Thicker coats of varnish take longer to dry than thinner coats.

- The temperature: Varnish dries faster in warm temperatures than in cold temperatures.

- The humidity: Varnish dries faster in low humidity than in high humidity.

9. What are the different ways to remove varnish?

There are several different ways to remove varnish, including:

- Chemical strippers: These products are applied to the varnish and allowed to sit for a period of time. They then dissolve the varnish, which can be scraped off.

- Heat guns: These tools use hot air to soften the varnish, which can then be scraped off.

- Sanding: This method involves using sandpaper to remove the varnish. It is the most time-consuming method, but it is also the most effective.

10. What are the different types of equipment that are used in varnishing?

There are several different types of equipment that are used in varnishing, including:

- Brushes: Brushes are used to apply varnish to surfaces.

- Rollers: Rollers are used to apply varnish to large, flat surfaces.

- Spray guns: Spray guns are used to apply varnish to large, complex surfaces.

- Sanding equipment: Sanding equipment is used to prepare surfaces for varnishing and to remove old varnish.

- Safety equipment: Safety equipment, such as respirators and gloves, is used to protect the user from the fumes and chemicals used in varnishing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnisher Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnisher Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Varnisher Apprentice supports the Varnisher in applying a protective or decorative coating to wood, metal, and other surfaces. Their key responsibilities include:

1. Assist with surface preparation

Prepare surfaces by cleaning, sanding, and masking to ensure proper adhesion of coatings.

- Remove dirt, dust, and debris from surfaces.

- Sand surfaces to smooth irregularities and create a uniform finish.

- Apply masking tape to protect areas that should not be coated.

2. Mix and apply coatings

Mix coatings according to manufacturer’s instructions and apply them using brushes, rollers, or spray guns.

- Calculate the correct proportions of coating materials.

- Stir or shake coatings thoroughly to ensure proper mixing.

- Apply coatings evenly and smoothly to achieve a uniform finish.

3. Inspect and repair coatings

Inspect coated surfaces for defects, such as bubbles, runs, or drips, and repair them as necessary.

- Identify and correct defects in coatings.

- Touch up areas where coatings have been damaged.

- Ensure that coated surfaces meet quality standards.

4. Perform general maintenance

Maintain a clean and organized work area, and perform general maintenance tasks, such as cleaning equipment and tools.

- Keep work area free of debris and hazards.

- Clean and maintain equipment and tools to ensure proper operation.

- Report any equipment or tool malfunctions to the supervisor.

Interview Tips

Preparing thoroughly for a Varnisher Apprentice interview can significantly increase your chances of success. Here are some tips and a sample outline to help you stand out:

1. Research the company and position

Demonstrate your interest and enthusiasm by researching the company’s history, values, and products. Familiarize yourself with the specific requirements of the Varnisher Apprentice role to highlight your relevant skills and experience.

2. Practice your answers

Prepare responses to common interview questions related to your skills, experience, and motivations. Practice speaking clearly and confidently to convey your abilities effectively.

3. Highlight your attention to detail

Emphasize your meticulousness and attention to detail, which are crucial qualities for a Varnisher Apprentice. Share examples of your ability to follow instructions precisely and produce high-quality work.

4. Demonstrate your commitment to safety

The Varnisher Apprentice role involves handling potentially hazardous materials and equipment. Highlight your understanding of safety protocols and your commitment to working in a safe and responsible manner.

5. Be prepared to ask questions

Asking well-thought-out questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions that show your curiosity about the company, the role, or the industry.

Example Outline

Consider structuring your answers using the following outline:

- Tell me about yourself and your experience. Briefly introduce yourself and highlight your most relevant skills and experience for the Varnisher Apprentice role.

- Why are you interested in this position? Explain your reasons for pursuing the Varnisher Apprentice position and how it aligns with your career goals.

- What are your strengths and weaknesses? Discuss your strengths and weaknesses, emphasizing transferable skills and areas where you are eager to learn and grow.

- How do you handle working in a fast-paced environment? Describe your ability to prioritize tasks, manage time, and work under pressure.

- What sets you apart from other candidates? Highlight your unique qualifications, skills, or experiences that make you an exceptional candidate.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Varnisher Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!