Are you gearing up for a career in Veneer Drier? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Veneer Drier and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

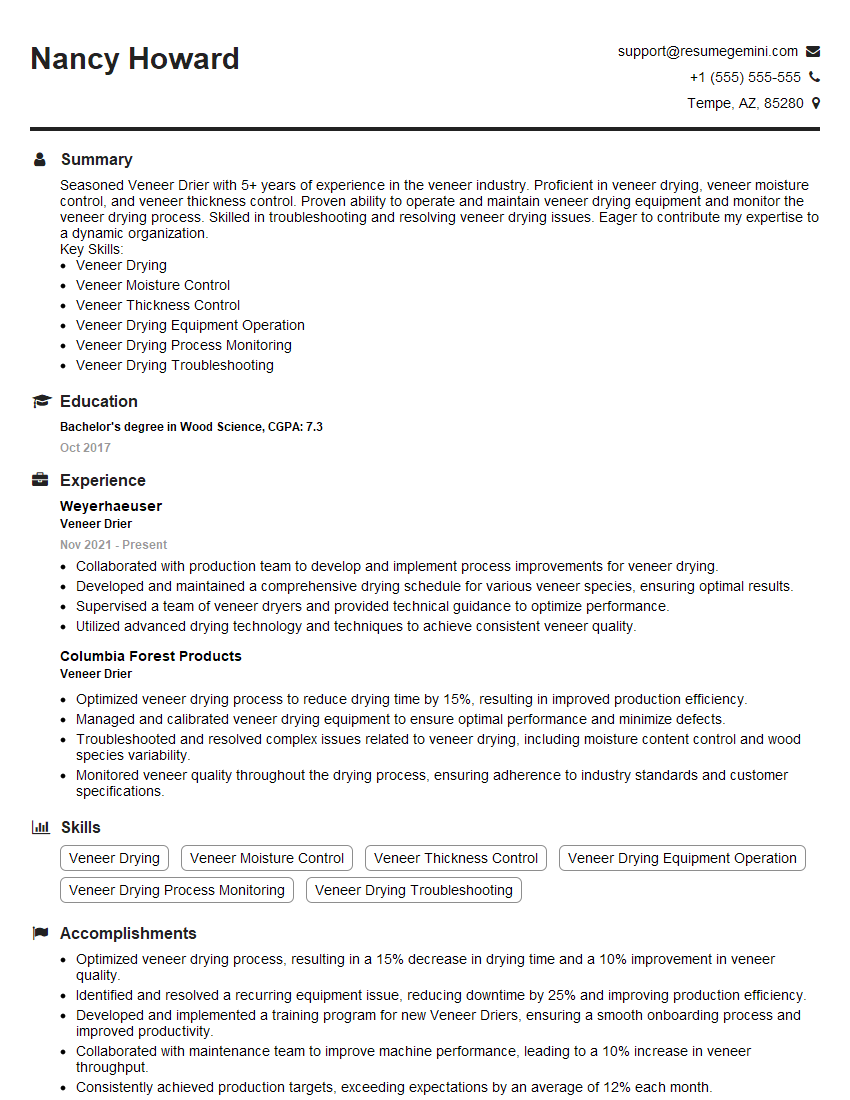

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Drier

1. What is the role of the veneer dryer in the veneer production process?

In the veneer production process, the veneer dryer plays a critical role in removing moisture from the veneer sheets. This process is essential for achieving the desired moisture content for the veneer to be suitable for further processing and use in the manufacture of plywood, furniture, and other wood products.

2. Describe the different types of veneer dryers commonly used in the industry.

- Roller dryers: These dryers consist of a series of heated rollers that the veneer sheets pass through. The heat from the rollers evaporates the moisture from the veneer.

- Conveyor dryers: These dryers use a conveyor belt to transport the veneer sheets through a heated chamber. The heat and airflow in the chamber dry the veneer.

- Vacuum dryers: Vacuum dryers use a vacuum to reduce the pressure around the veneer sheets. This allows the moisture to evaporate more quickly from the veneer.

3. How do you determine the optimal drying temperature and time for different types of veneer?

- Veneer species: Different veneer species have different moisture contents and drying characteristics. The drying temperature and time need to be adjusted to suit the specific species.

- Veneer thickness: Thicker veneers require longer drying times than thinner veneers.

- Moisture content: The initial moisture content of the veneer will affect the drying time.

4. What are the common defects that can occur during veneer drying and how do you prevent them?

- Buckling: This occurs when the veneer sheets warp or bend during drying. It can be prevented by maintaining uniform drying conditions and applying pressure to the veneer as it dries.

- Casehardening: This occurs when the surface of the veneer dries faster than the interior, resulting in a hard, brittle surface. It can be prevented by controlling the drying temperature and humidity.

- Collapse: This occurs when the veneer sheets collapse or shrink during drying. It can be prevented by using a vacuum dryer or by applying pressure to the veneer as it dries.

5. How do you maintain and troubleshoot veneer dryers to ensure optimal performance?

- Regular cleaning: Removing dust and debris from the dryer is essential for maintaining efficient airflow and heat transfer.

- Inspection of rollers: Checking the rollers for wear and damage is crucial to prevent uneven drying and veneer damage.

- Temperature monitoring: Regularly monitoring the temperature of the dryer ensures accurate and consistent drying conditions.

- Conveyor belt maintenance: Inspecting and replacing worn or damaged conveyor belts is vital for smooth veneer transportation and drying.

- Troubleshooting: Identifying and resolving issues such as uneven drying, excessive shrinkage, or noise during operation is essential for maintaining optimal dryer performance.

6. How do you optimize energy efficiency in veneer drying operations?

- Utilizing energy-efficient dryers: Choosing dryers equipped with advanced technologies, such as heat recovery systems, can significantly reduce energy consumption.

- Optimizing drying conditions: Fine-tuning drying parameters, including temperature, humidity, and airflow, based on veneer characteristics can minimize energy usage.

- Implementing heat recovery systems: Recovering and reusing heat generated during the drying process can substantially improve energy efficiency.

- Regular maintenance: Ensuring dryers are well-maintained and operating efficiently helps prevent energy wastage.

7. How do you prioritize safety when operating and maintaining veneer dryers?

- Regular safety inspections: Conduct thorough inspections of the dryer and its components to identify any potential hazards.

- Proper ventilation: Ensure adequate ventilation to prevent the buildup of harmful fumes and maintain a safe working environment.

- Guarding moving parts: Securely guard all moving parts of the dryer to prevent contact and accidents.

- Electrical safety: Ensure proper grounding, insulation, and regular inspection of electrical components to prevent electrical hazards.

- Emergency procedures: Establish clear emergency procedures and train personnel on how to respond to potential incidents, such as fire or equipment malfunction.

8. What are the key quality control measures implemented to ensure the production of high-quality veneer?

- Moisture content monitoring: Regularly monitoring the moisture content of veneer sheets ensures they meet the desired specifications.

- Visual inspection: Inspecting veneer sheets for defects, such as cracks, knots, or discoloration, is crucial for maintaining quality.

- Thickness measurement: Verifying the thickness of veneer sheets to meet required standards is essential.

- Grain orientation: Ensuring proper grain orientation of veneer sheets optimizes strength and aesthetic qualities.

- Documentation and traceability: Maintaining accurate records and tracking veneer production allows for quality control and traceability throughout the process.

9. How do you stay updated with the latest advancements and technologies in veneer drying?

- Industry conferences and exhibitions: Attending industry events provides an opportunity to learn about the latest developments and connect with experts.

- Technical publications and white papers: Reading industry-related publications and research papers helps stay informed about technological advancements.

- Manufacturer training and workshops: Participating in training programs offered by veneer dryer manufacturers enables gaining knowledge about new technologies and best practices.

- Online webinars and courses: Utilizing online resources and platforms offers convenient access to educational content and industry updates.

10. How do you manage a team of veneer dryer operators and ensure efficient operations?

- Clear communication: Establishing clear lines of communication and providing regular updates to the team is essential.

- Training and development: Providing comprehensive training to operators on the operation and maintenance of veneer dryers ensures proficiency.

- Performance monitoring: Tracking and evaluating the performance of operators helps identify areas for improvement.

- Safety protocols: Enforcing strict safety protocols and ensuring operators adhere to them is paramount.

- Teamwork and collaboration: Fostering a collaborative work environment promotes teamwork and problem-solving.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Driers play a crucial role in the veneer production process. They are responsible for drying, flattening, and shaping veneer sheets to prepare them for further processing.

1. Drying Veneer Sheets

Operate and monitor veneer dryers to remove moisture from veneer sheets.

- Control temperature, humidity, and airflow within the dryers to ensure proper drying conditions.

- Monitor veneer moisture content to determine when drying is complete.

2. Flattening and Shaping Veneer Sheets

Operate and adjust veneer flattening machinery to remove wrinkles and flatten veneer sheets.

- Inspect veneer sheets for defects and remove any damaged or unusable material.

- Use presses and other equipment to shape veneer sheets to desired dimensions and shapes.

3. Monitoring and Maintenance

Monitor dryer performance and make adjustments as needed to maintain optimal drying conditions.

- Perform regular maintenance and repairs on dryers and associated equipment.

- Maintain records of dryer performance and maintenance activities.

4. Safety and Compliance

Follow established safety procedures and regulations while operating dryers.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Veneer Drier interview requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace the interview.

1. Research the Company and Position

Review the company’s website, annual reports, and news articles to gain insights into their business operations and the specific role of the Veneer Drier.

- Identify key responsibilities and qualifications for the position.

- Tailor your resume and cover letter to highlight relevant skills and experience.

2. Practice Answering Common Interview Questions

Anticipate and prepare answers to common interview questions related to your technical skills, experience, and teamwork abilities.

- For example, you may be asked about your knowledge of dryer types, drying techniques, or safety protocols.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers that demonstrate your abilities.

3. Showcase Your Technical Proficiency

Be prepared to discuss your technical expertise in veneer drying, including your understanding of dryer operations, moisture control, and quality assurance.

- Provide specific examples of how you have applied these skills to improve drying efficiency or resolve production issues.

- Highlight any certifications or training you have received in veneer drying or related fields.

4. Emphasize Your Attention to Detail and Safety

Veneer Driers must be meticulous in their work and prioritize safety in the workplace.

- Describe your attention to detail in monitoring dryer performance and identifying potential problems.

- Discuss your commitment to following safety protocols and maintaining a safe work environment.

Next Step:

Now that you’re armed with the knowledge of Veneer Drier interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Veneer Drier positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini