Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Joiner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

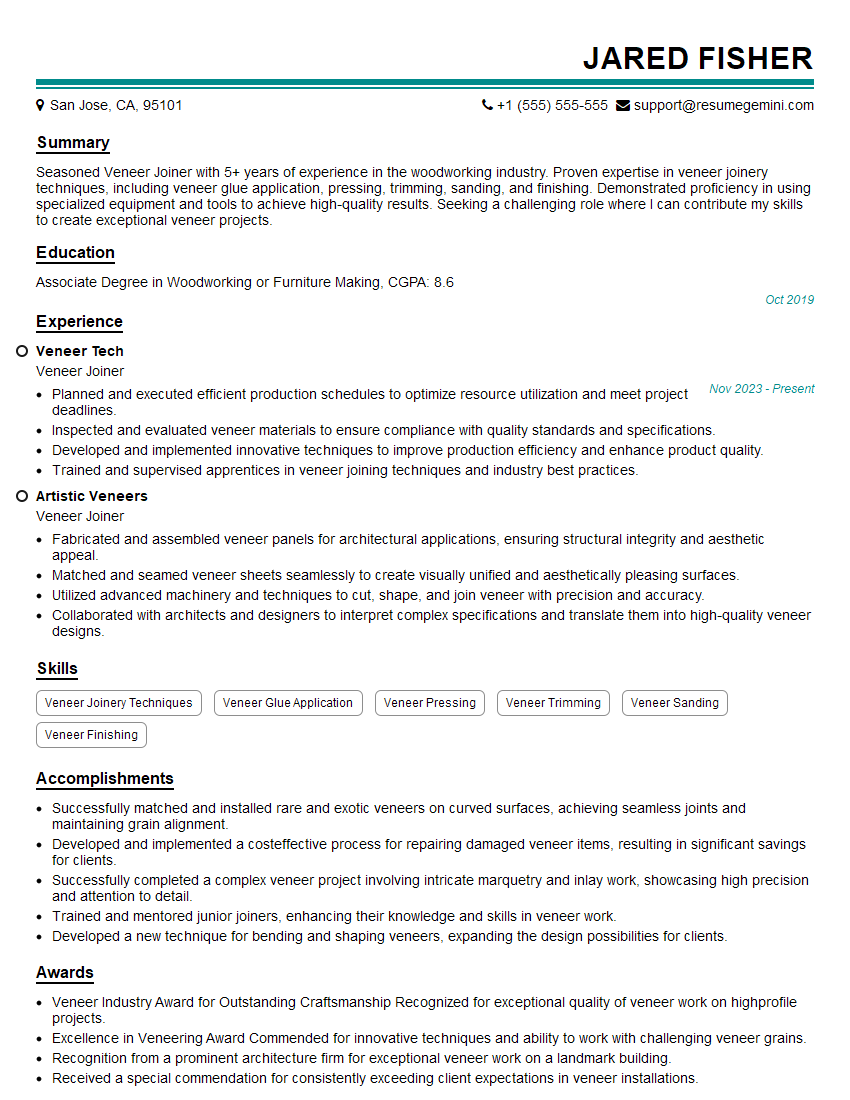

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Joiner

1. What are the main differences between hot and cold press veneering?

- Hot press veneering uses heat and pressure to bond the veneer to the substrate, while cold press veneering uses only pressure.

- Hot press veneering produces a stronger bond than cold press veneering, but it can also damage the veneer if the temperature is too high.

- Cold press veneering is a slower process than hot press veneering, but it is less likely to damage the veneer.

2. What are the different types of veneer joints?

Edge Joints

- Butt joint: This is the simplest type of edge joint, where the edges of two pieces of veneer are simply butted together.

- Miter joint: This is a more complex joint, where the edges of two pieces of veneer are mitered at a 45-degree angle.

- Scarf joint: This is a strong joint, where the edges of two pieces of veneer are overlapped and glued together.

Face Joints

- Bookmatched veneer: This is a joint where two pieces of veneer are flipped over and placed next to each other, so that the grain pattern matches.

- Slipmatched veneer: This is a joint where two pieces of veneer are placed next to each other, but the grain pattern is not matched.

- Random matched veneer: This is a joint where pieces of veneer are placed together in a random pattern.

3. What are the different types of veneer?

- Rotary cut veneer: This is the most common type of veneer, and it is made by slicing the log around its circumference.

- Sliced veneer: This type of veneer is made by slicing the log parallel to its grain.

- Half-round veneer: This type of veneer is made by slicing the log in half, and then slicing the half-round piece into thin sheets.

- Quarter cut veneer: This type of veneer is made by slicing the log into quarters, and then slicing the quarters into thin sheets.

4. What are the different types of veneer substrates?

- Particleboard: This is a type of substrate that is made from wood chips and resin.

- Medium-density fiberboard (MDF): This is a type of substrate that is made from wood fibers and resin.

- High-density fiberboard (HDF): This is a type of substrate that is made from wood fibers and resin, and it is denser than MDF.

- Plywood: This is a type of substrate that is made from layers of wood veneer that are glued together.

5. What are the different tools and equipment used in veneer joinery?

- Veneer saw: This is a saw that is used to cut veneer.

- Veneer press: This is a press that is used to apply pressure to veneer joints.

- Veneer clamps: These are clamps that are used to hold veneer in place while it is being glued.

- Veneer scraper: This is a tool that is used to remove excess glue from veneer joints.

- Veneer sander: This is a sander that is used to smooth veneer surfaces.

6. What are the different safety precautions that should be taken when working with veneer?

- Wear a dust mask when working with veneer, as the dust can be harmful to your lungs.

- Wear gloves when working with veneer, as the chemicals in the glue can irritate your skin.

- Use sharp tools when working with veneer, as dull tools can cause the veneer to tear.

- Be careful when using power tools, as they can be dangerous if they are not used properly.

7. What is the best way to achieve a strong bond between veneer and substrate?

- Use a high-quality veneer adhesive.

- Apply the adhesive evenly to both the veneer and the substrate.

- Press the veneer onto the substrate with even pressure.

- Allow the adhesive to dry completely before using the veneered piece.

8. What are the different types of finishes that can be applied to veneer?

- Oil finish: This type of finish is made from natural oils, such as linseed oil or tung oil.

- Lacquer finish: This type of finish is made from a synthetic resin.

- Polyurethane finish: This type of finish is made from a polyurethane resin.

- Wax finish: This type of finish is made from a natural wax, such as beeswax or carnauba wax.

9. What are the different factors that affect the cost of veneer?

- The type of wood: Some types of wood are more expensive than others.

- The thickness of the veneer: Thicker veneers are more expensive than thinner veneers.

- The quality of the veneer: Higher quality veneers are more expensive than lower quality veneers.

- The supply and demand for veneer: If there is a high demand for a particular type of veneer, the price will be higher.

10. What are the different career opportunities for veneer joiners?

- Cabinetmaker: Cabinetmakers build and repair cabinets, furniture, and other wooden structures.

- Furniture maker: Furniture makers build and repair furniture.

- Boatbuilder: Boatbuilders build and repair boats.

- Musical instrument maker: Musical instrument makers build and repair musical instruments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Joiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Joiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer joiners are highly skilled craftsmen who are responsible for the production and installation of high-quality veneer products. Their work is essential for the creation of beautiful and durable furniture, cabinetry, and other products.

1. Producing Veneer

Veneer joiners begin their work by producing veneer, a thin layer of wood that is used to cover other surfaces. They use specialized equipment to cut and shape the veneer, ensuring that it is the correct size and thickness. Veneer joiners must also be able to match the grain and color of the veneer to the surface it will be applied to.

- Selecting and preparing the wood

- Cutting the veneer to the desired thickness

- Matching the grain and color of the veneer to the surface it will be applied to

2. Applying Veneer

Once the veneer is produced, veneer joiners must apply it to the surface of the product. They use a variety of techniques to do this, including glue, nails, and clamps. Veneer joiners must be able to apply the veneer smoothly and evenly, ensuring that there are no gaps or bubbles.

- Applying glue to the surface of the product

- Placing the veneer on the surface of the product

- Using nails or clamps to hold the veneer in place

- Smoothing out the veneer with a roller or brush

3. Finishing Veneer

Once the veneer has been applied, veneer joiners must finish it to protect it from damage and to give it a beautiful appearance. They may use a variety of finishing techniques, including sanding, staining, and lacquering. Veneer joiners must be able to finish the veneer to a high standard, ensuring that it is smooth, durable, and aesthetically pleasing.

- Sanding the veneer to remove any rough edges

- Staining the veneer to match the desired color

- Applying a lacquer to protect the veneer from damage

- Buffing the veneer to a high shine

4. Maintaining Equipment

Veneer joiners must also be able to maintain their equipment to ensure that it is in good working order. They may be responsible for cleaning, lubricating, and repairing their equipment. Veneer joiners must also be able to troubleshoot any problems that may arise with their equipment.

- Cleaning the equipment

- Lubricating the equipment

- Repairing the equipment

- Troubleshooting any problems that may arise

Interview Tips

Interviewing for a veneer joiner position can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you to understand the company’s culture, values, and products. You should also learn about the specific position you are applying for. This will help you to answer the interviewer’s questions intelligently and show that you are interested in the position.

- Visit the company’s website

- Read articles about the company in trade publications

- Talk to people who work for the company

2. Practice Your Answers

Once you have researched the company, you should practice answering common interview questions. This will help you to feel more confident and prepared during your interview. You should also be prepared to talk about your skills and experience, and how they relate to the position you are applying for.

- Write down your answers to common interview questions

- Practice your answers with a friend or family member

- Time yourself to make sure you are not giving long-winded answers

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing too much jewelry or perfume

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident and authentic, and let your personality shine through.

- Be yourself

- Don’t try to be someone you’re not

- Be confident and authentic

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Joiner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.