Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

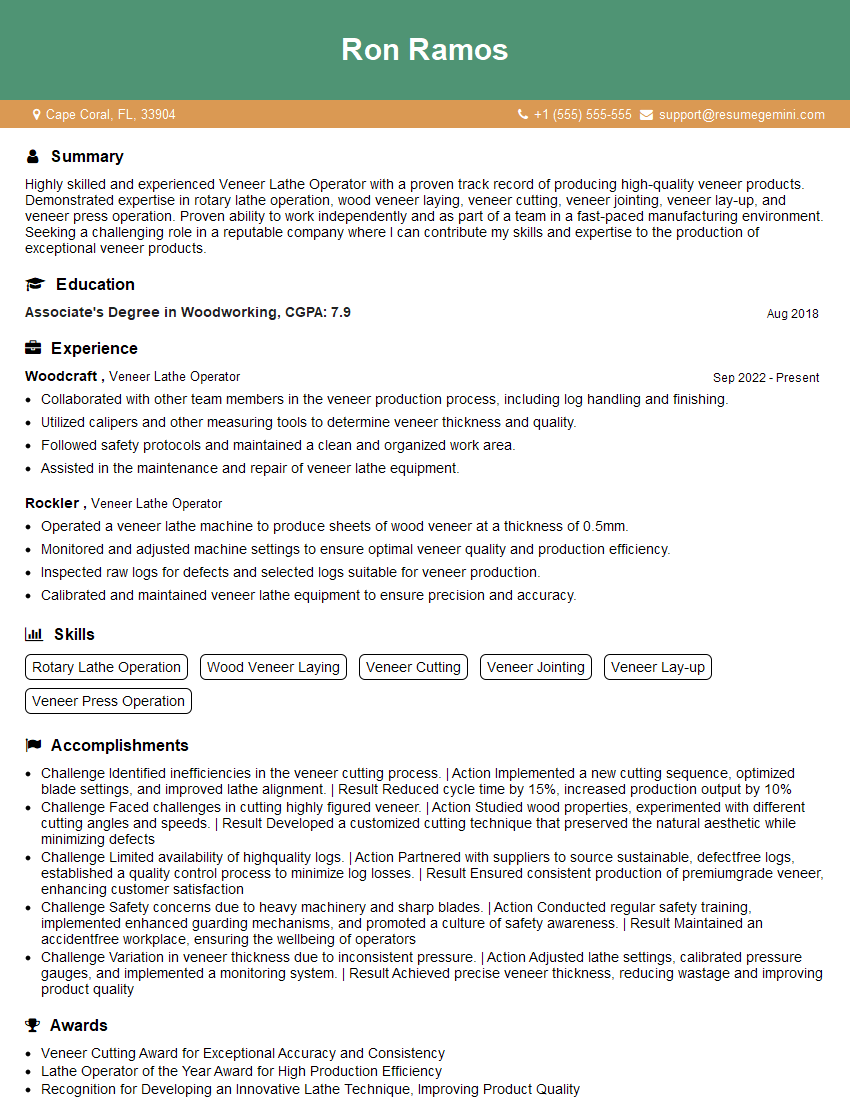

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Lathe Operator

1. Describe the process of calibrating a veneer lathe?

To calibrate a veneer lathe, I follow these steps:

- Inspect the lathe and ensure that all components are in good working order.

- Mount a test block of wood on the lathe’s chuck.

- Use a dial indicator to measure the thickness of the veneer being cut.

- Adjust the lathe’s settings until the desired veneer thickness is achieved.

- Repeat the process with different test blocks to ensure accuracy.

2. How do you troubleshoot a veneer lathe when it is producing uneven veneer?

Inspect the cutting blade

- Check for dullness or damage to the blade.

- Ensure the blade is properly tensioned and aligned.

Examine the log or block

- Inspect the log for knots, cracks, or other defects that may affect veneer thickness.

- Check the block’s alignment on the lathe’s chuck.

Evaluate lathe settings

- Verify that the cutting speed, feed rate, and pressure are optimal for the wood species being cut.

- Inspect the lathe’s bearings and other mechanical components for wear or damage.

3. What are the key factors that affect the quality of veneer produced by a lathe?

- Log quality: The species, age, and condition of the log can significantly impact veneer quality.

- Lathe settings: The cutting speed, feed rate, and pressure must be optimized for the log and desired veneer thickness.

- Blade sharpness: A sharp blade produces smoother, more consistent veneer.

- Lathe maintenance: Regular maintenance and calibration ensure that the lathe operates accurately and efficiently.

4. How do you minimize waste and defects during veneer production?

- Proper log selection: Carefully inspect logs for defects and select those with minimal knots and cracks.

- Optimized cutting techniques: Utilize techniques such as skip-cutting and quarter-cutting to reduce waste and improve veneer quality.

- Blade maintenance: Sharpen and replace blades regularly to minimize tearing and defects.

- Lathe monitoring: Pay attention to the lathe’s performance and make adjustments as needed to maintain consistent veneer thickness.

5. Describe the safety precautions that must be followed when operating a veneer lathe?

- Wear proper protective gear: This includes safety glasses, earplugs, and gloves.

- Securely mount the log or block: Ensure that the workpiece is securely fastened to the lathe’s chuck.

- Maintain a clean work area: Keep the lathe and surrounding area free of debris and tripping hazards.

- Stay alert and focused: Avoid distractions and pay attention to the lathe’s operation.

- Follow established safety protocols: Adhere to all company and industry safety regulations.

6. How do you calculate the maximum sheet size that can be produced from a given log diameter?

- Measure the log diameter: Determine the diameter of the log at its thickest point.

- Subtract the core size: Estimate the size of the unusable core in the center of the log.

- Divide by 2: Divide the remaining diameter by 2 to get the maximum flat-cut veneer sheet width.

- Adjust for curvature: Consider the log’s natural curvature and adjust the maximum width accordingly.

7. What are the different types of veneer lathes, and what are their advantages and disadvantages?

- Rotary lathes:

- Advantages: High production rate, efficient use of logs

- Disadvantages: Can produce tear-outs, limited veneer thickness range

- Slicing lathes:

- Advantages: Produces high-quality, consistent veneer, wide thickness range

- Disadvantages: Slower production rate, more complex setup

8. How do you determine the appropriate veneer thickness for a particular application?

- Consider the application: Different applications, such as furniture, flooring, or musical instruments, require different veneer thicknesses.

- Evaluate the wood species: Different wood species have varying densities and strength characteristics, which influence the optimal veneer thickness.

- Match the design requirements: The desired aesthetic and functional qualities of the final product often dictate the appropriate veneer thickness.

9. What are the common defects found in veneer, and how can they be prevented?

- Splitting: Can be prevented by using sharp blades, properly supporting the log, and minimizing cutting pressure.

- Tearing: Can be avoided through proper blade tensioning, using a sharp blade, and maintaining correct lathe settings.

- Buckling: Can be prevented by controlling moisture levels in the veneer and using a flattener.

- Warping: Can be minimized by using a properly seasoned log and drying the veneer slowly and evenly.

10. Describe the steps involved in preparing veneer for use in furniture production.

- Cutting: Veneer sheets are cut to the desired size and shape.

- Jointing: Sheets are joined together to create larger panels.

- Matching: Veneer is matched for grain, color, and texture to achieve the desired aesthetic.

- Pressing: Veneer is pressed onto a substrate material, such as plywood or MDF.

- Finishing: The finished veneer is sanded, stained, and sealed to protect and enhance its appearance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Lathe Operators work in a manufacturing environment, primarily responsible for operating and maintaining veneer lathes that cut wood into thin sheets of veneer. They ensure the smooth and efficient operation of the lathe, while adhering to safety regulations and maintaining high-quality standards. Their primary duties include:

1. Inspecting Raw Materials and Equipment

Before commencing operations, Veneer Lathe Operators inspect raw logs and equipment to ensure they meet specifications. This involves checking log quality, size, and moisture content, as well as verifying that the lathe and its components are in good working order.

2. Operating the Veneer Lathe

They operate the lathe to cut logs into thin, continuous sheets of veneer. This requires precision and skill to ensure the veneer is uniform in thickness and quality. Operators adjust machine settings, monitor the cutting process, and make necessary adjustments to maintain optimal performance.

3. Maintaining Veneer Lathes

Veneer Lathe Operators are responsible for maintaining the lathe and its components to ensure its continued operation. This includes regular cleaning, lubrication, and minor repairs. They also conduct routine inspections to identify potential issues and take preventive measures.

4. Monitoring Veneer Quality

During the cutting process, Operators monitor the quality of the veneer being produced. They inspect the veneer for defects, such as knots, splits, or discoloration, and make adjustments as needed to minimize waste and maintain product quality.

5. Observing Safety Regulations

Veneer Lathe Operators prioritize safety by adhering to established safety protocols. They wear appropriate protective gear, such as gloves, safety glasses, and earplugs. They also follow proper lifting techniques and avoid operating the lathe under unsafe conditions.

Interview Tips

To ace the interview for a Veneer Lathe Operator position, candidates should prepare thoroughly and showcase their knowledge and skills. Here are some interview tips and preparation hacks:

1. Research the Company and the Role

Familiarize yourself with the company’s history, operations, and industry reputation. Research the specific role and its responsibilities to demonstrate your understanding of the job’s requirements.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating veneer lathes or similar machinery. Quantify your accomplishments, using specific metrics to demonstrate your productivity and efficiency.

3. Practice Responding to Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about your experience operating a veneer lathe” or “How do you maintain a lathe for optimal performance?” Practice your responses to ensure clarity and confidence.

4. Be Enthusiastic and Professional

Show your passion for the industry and your eagerness to contribute to the company. Maintain a positive attitude throughout the interview and ask thoughtful questions to demonstrate your engagement and interest.

5. Prepare Questions for the Interviewer

Preparing questions to ask the interviewer shows your interest in the company and the role. Questions about training opportunities, career advancement, or the company’s sustainability practices demonstrate your proactive approach.

6. Dress Professionally and Arrive on Time

Make a good first impression by dressing appropriately and arriving on time for your interview. This reflects your respect for the company and the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!