Feeling lost in a sea of interview questions? Landed that dream interview for Veneer Layer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Veneer Layer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

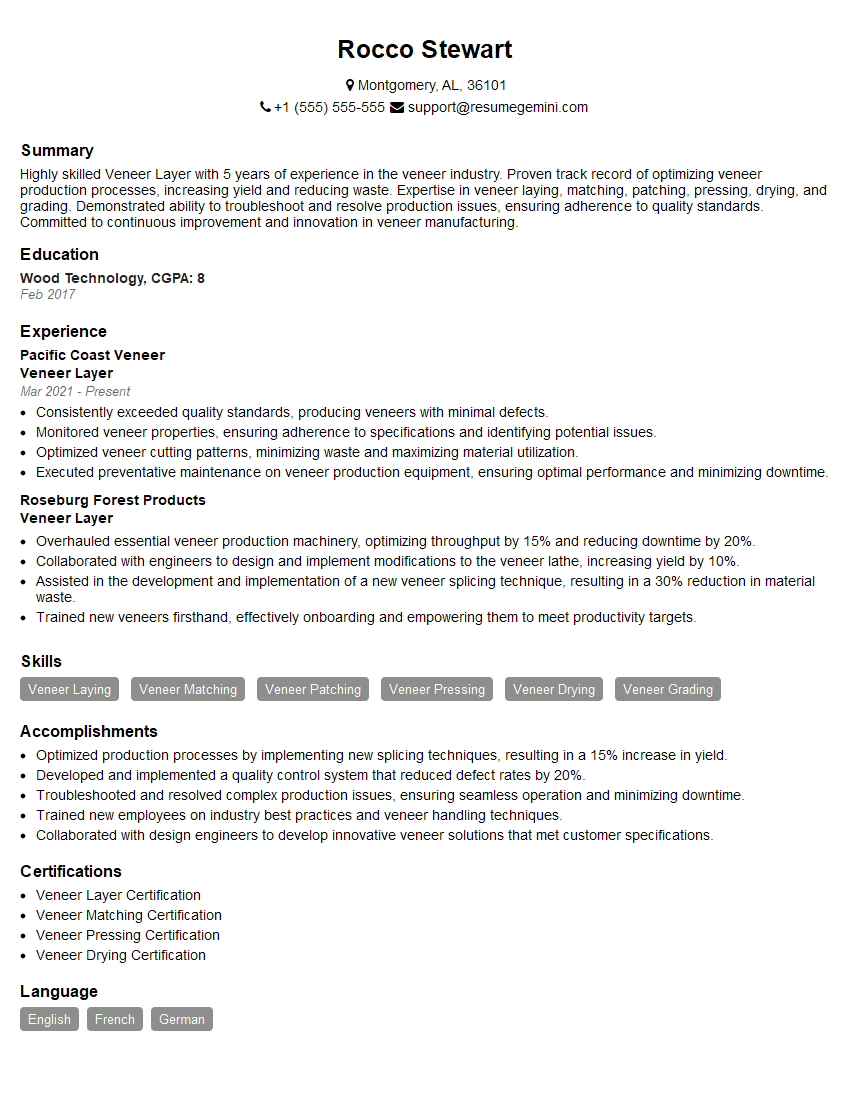

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Layer

1. What are the different types of veneer?

There are three main types of veneer: sliced veneer, rotary veneer, and half-round veneer. Sliced veneer is made by slicing thin sheets of wood from a log. Rotary veneer is made by peeling a continuous sheet of wood from a log. Half-round veneer is made by cutting a log in half and then slicing sheets of wood from the half-log.

2. What are the advantages and disadvantages of using veneer?

Advantages of veneer

- Veneer is a relatively inexpensive way to add the beauty of real wood to a project.

- Veneer is available in a wide variety of species, colors, and grain patterns.

- Veneer is easy to work with, making it a good choice for DIY projects.

Disadvantages of veneer

- Veneer is not as durable as solid wood.

- Veneer can be damaged by heat and moisture.

- Veneer can be difficult to repair.

3. What are the different types of adhesives used for veneer?

There are three main types of adhesives used for veneer: water-based adhesives, solvent-based adhesives, and hot-melt adhesives. Water-based adhesives are the most common type of adhesive used for veneer. They are easy to use and cleanup, and they provide a strong bond. Solvent-based adhesives are stronger than water-based adhesives, but they can be more difficult to use and cleanup. Hot-melt adhesives are the strongest type of adhesive used for veneer. They provide a very strong bond, but they can be difficult to use and cleanup.

4. How do you prepare a surface for veneering?

To prepare a surface for veneering, you will need to sand the surface smooth and clean it with a tack cloth. You will also need to apply a coat of veneer adhesive to the surface. The adhesive should be applied evenly and thinly.

5. How do you apply veneer?

To apply veneer, you will need to place the veneer on the surface and press it down firmly. You will need to use a veneer hammer or a rolling pin to press the veneer into place. Once the veneer is in place, you will need to trim the edges of the veneer and sand the surface smooth.

6. How do you finish veneer?

To finish veneer, you will need to apply a finish to the surface. The finish can be a clear finish, such as polyurethane, or a colored finish, such as stain. The finish will protect the veneer from damage and give it a beautiful shine.

7. What are some common problems that can occur when veneering?

Some common problems that can occur when veneering include: bubbles, wrinkles, and tears. Bubbles can be caused by air getting trapped between the veneer and the surface. Wrinkles can be caused by the veneer not being applied smoothly. Tears can be caused by the veneer being torn during application. These problems can be avoided by taking care when preparing the surface, applying the veneer, and finishing the veneer.

8. What are some tips for veneering?

- Use a sharp knife to cut the veneer.

- Apply a thin, even coat of adhesive to the surface.

- Press the veneer into place firmly.

- Trim the edges of the veneer carefully.

- Sand the surface of the veneer smooth.

- Apply a finish to the surface of the veneer.

9. What are the different types of veneer machines?

There are three main types of veneer machines: veneer saws, veneer jointers, and veneer presses. Veneer saws are used to cut veneer into strips. Veneer jointers are used to join strips of veneer together. Veneer presses are used to press veneer onto a surface.

10. What are the safety precautions that should be taken when using veneer machines?

- Wear safety glasses and a dust mask when using veneer machines.

- Keep your hands away from moving parts.

- Do not use veneer machines if you are not properly trained.

- Follow all manufacturer’s instructions when using veneer machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Veneer Layer, your primary focus will be on cutting, handling, and assembling thin sheets of wood veneer to create decorative and protective surfaces.

1. Preperation of Veneer Sheets

You will ensure that veneer sheets are properly cut and prepared before applying them to surfaces.

- Plan and lay out the veneer sheets based on the required design and specifications.

- Cut veneers to precise dimensions using a variety of cutting tools, including saws, knives, and guillotines.

- Prepare veneer surfaces by sanding, scraping, and finishing as needed.

2. Veneer Application

You will skillfully apply prepared veneer sheets to surfaces using appropriate adhesives and techniques.

- Select and apply adhesives suitable for the veneer and substrate materials.

- Position and align veneer sheets on the surface, ensuring proper alignment and matching of patterns.

- Carefully apply pressure using clamps, rollers, or vacuums to bond the veneer to the surface.

3. Finishing and Maintenance

You will perform finishing and maintenance tasks to ensure the veneer’s durability and aesthetics.

- Sand, seal, and finish veneer surfaces to enhance their appearance and protection.

- Repair or replace damaged veneer sections as required, maintaining the integrity and beauty of the surfaces.

- Inspect veneer surfaces regularly to identify and address any maintenance needs.

4. Machinery Maintenance and Safety

You will be responsible for the proper maintenance and safe operation of equipment used in the veneering process.

- Perform routine maintenance and cleaning of cutting tools, compressors, and other equipment.

- Adhere to safety protocols and use appropriate personal protective equipment while operating machinery.

- Report any equipment malfunctions or potential hazards to ensure a safe work environment.

Interview Tips

Preparing for an interview for the Veneer Layer position requires careful research and a strong understanding of the role’s responsibilities and the industry.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and reputation. Research the veneer industry, including current trends, challenges, and technological advancements.

2. Highlight Relevant Experience and Skills

Emphasize your experience in veneer cutting, application, and finishing. Quantify your accomplishments and provide specific examples of projects where you demonstrated your skills.

3. Demonstrate Attention to Detail and Precision

Veneer work requires precision and attention to detail. Highlight your ability to work accurately and take pride in your craftsmanship.

4. Emphasize Safety and Quality

Safety and quality are critical in the veneer industry. Emphasize your commitment to following safety protocols and delivering high-quality results.

5. Show Enthusiasm and Passion

Demonstrate your enthusiasm for working with veneers and your passion for creating beautiful and durable surfaces.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Veneer Layer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.